Tall Buildings

Steel Core System Could Transform Office Tower Construction

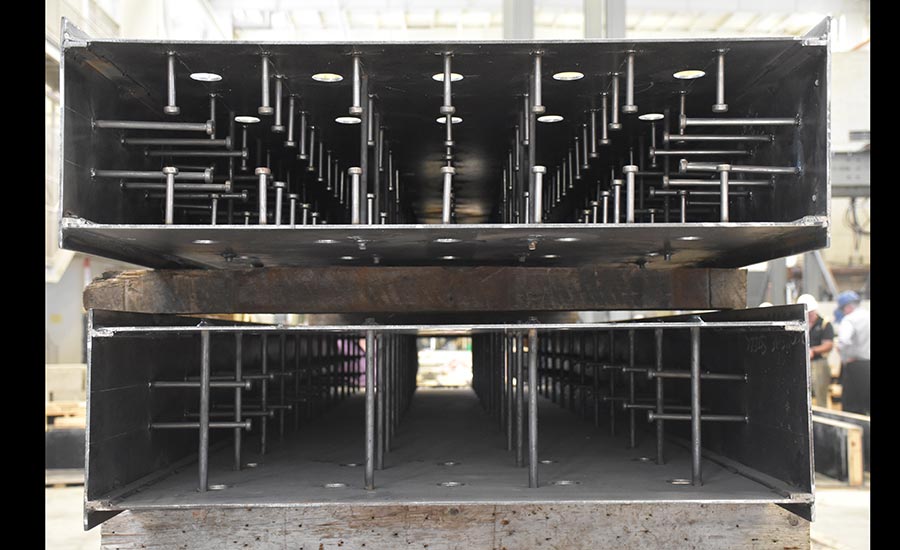

Coupled steel-plate test specimens, shown before concrete filling is added, have various spacing and quantities of cross ties and shear studs.

Photo courtesy of AISC

A radically different shear-wall core system for simpler and speedier construction of steel-framed high-rise office buildings is about to make its debut. The coupled steel-plate composite wall system—a sandwich of plates filled with concrete liberated of reinforcing steel—provides the strength, stiffness, safety and serviceability of a reinforced concrete core but is not burdened by rebar congestion and complex formwork, say structural engineers testing the system.

The sandwich wall, appropriate where either seismic or wind loads prevail, “fundamentally changes the game,” says Ron Klemencic, chairman and CEO of Magnusson Klemencic Associates (MKA) and the structural engineer pioneering its use. MKA predicts the system can slash superstructure construction time in half.

There is no time lost to install rebar—the plates serve that function. There is no formwork—the plates serve that function, as well. Absent formwork, rebar and curing time for the concrete, the core and perimeter steel can rise in concert, rather than the slower core leading—and delaying—the quicker steel, says Klemencic.

Another plus is that core wall sections are prefabricated into modules, complete with tie rods that separate the plates and shear studs. And the modular walls do triple duty as falsework for construction loads before the concrete filling is added.

The conventional hybrid system—a reinforced concrete core with perimeter steel columns and floor systems of steel beams supporting a composite metal deck—also results in tolerance issues where the beams connect to the core. Steel tolerances, set by the American Institute of Steel Construction (AISC), are tighter than concrete tolerances, set by the American Concrete Institute. Under the steel-plate system, steel connects to steel, eliminating tolerance issues and overlapping trade issues.

Faster, Simpler, Safer

All told, construction is faster, simpler and safer than it is with a hybrid system, says Klemencic. “If successful, the new approach will transform the marketplace,” he predicts.

A $600,000 study, jointly sponsored by the Charles Pankow Foundation and AISC, is under way to adapt the composite steel walls—first used in the U.S. in the nuclear powerplant sector because they are virtually impenetrable—for high-rise buildings.

Tests were needed for commercial applications because nuclear structures have long squat walls, dominated by shear, and high-rises have tall slender walls, dominated by flexure, says Amit H. Varma, director of the Robert L. and Terry L. Bowen Laboratory at Purdue University, which is conducting the three-year research program in conjunction with the University at Buffalo. Varma, who began testing the system in 2005 for nuclear powerplants, is principal investigator for the current study, working with UB’s Michel Bruneau.

The research is subjecting six specimens to axial force and cyclic lateral loading and evaluating the structural behavior, including stiffness, strength and drift capacity. The specimens have different variables, such as spacing and numbers of cross rods and shear studs.

Preliminary results of the first of six physical tests on coupled steel-plate composite shear-wall specimens indicate excellent behavior and cyclic performance. Photo Courtesy of AISC |

The goal is to generate experimental data and numerical models that will provide insights into the behavior of the system and allow the development of seismic and wind design provisions. “We are trying to optimize the design so it becomes more cost effective,” says Varma.

The team completed the first physical test late last month. Preliminary results indicate “excellent behavior and cyclic performance of the specimen,” says Varma.

The limit states are as expected, but the specimen strength is even greater than that calculated using simple methods, code equations or even finite element models, he adds.

Five more tests will be conducted at Bowen to evaluate the influence of parameters such as the axial load level, tie bar spacing and the use of shear studs along with tie bars.

Limitations

The sandwich does have some limitations. It is easier to cut into concrete in the field. With the steel wall system, it is best to plan, coordinate and detail all openings before shop fabrication, says Klemencic.

In addition, there are issues relating to detailing the module-to-module connections and the design and detailing of the coupling beams that separate and link modules to create doorways and other large spaces between modules.

Also, the system is not covered in the prescriptive provisions of the building codes. To date, to use it, engineers must do performance-based design, which requires peer review.

The AISC steel specification addresses the walls, based on research performed for the nuclear powerplant sector. The new studies will result in expanded information in AISC specifications, says Varma.

In addition to the Purdue-UB research, AISC and the Pankow Foundation are co-funding a FEMA P-695 computational study at UB, also with Purdue, set to wrap up next year. Researchers expect that coupled systems are more ductile and have more redundancy, but the American Society of Civil Engineers (ASCE), which develops the design standard for structures, currently does not assign coupled systems higher seismic response factors, called R-factors.

This study uses the FEMA P-695 methodology to substantiate the R-factors for the sandwich system. The additional research, costing $166,000, is expected to demonstrate that the sandwich systems are rated with the highest R-factor of any shear wall system of any material—an R-8 factor, says Lawrence F. Kruth, AISC’s vice president for structural engineering and research. The seismic factors developed will eventually be incorporated into the ASCE structural standard—known as ASCE 7.

Regarding the Bowen tests, Varma expects to have test data on the first six specimens by the end of the year. The second phase of testing, at UB, will begin on C-in-plan-shaped walls, which consist of three connected wall modules. The final tests, at Purdue, will be on composite dual-plate coupling beams, which, like doorway headers, connect separated modules and dissipate energy during an earthquake. The $600,000 study concludes in 2019.

“The goal is to have the wind design provisions in the main AISC specification and the seismic design provisions in the AISC seismic specification,” probably by 2022, says Varma.

First Use

MKA is eagerly anticipating the research results, which it hopes will support less-expensive walls with fewer ties. But it is not waiting for the design guidance to move on the first use of the system in a tall building. It already has approval to use the system in an 850-ft-tall office and residential tower in Seattle, set to start construction in January. Absent the research, MKA’s performance-based design for the tower, called Rainier Square, is conservative.

Klemencic figures the system is most cost-effective for a building 40 stories or taller, mostly based on the required thickness of the steel plate. For the 58-story Rainier Square project, the team, which includes Lease Crutcher Lewis as the contractor, the Supreme Group as steel fabricator and the Erection Co. as the steel erector, is working out the construction details by building a full-scale mock-up.

The team expects to have the self-consolidating concrete filling—cast a floor at a time through openings at the tops of the walls—trail all the structural steel framing by four floors. The plan is to field-weld the modules together. Klemencic expects the building to be finished by late 2020.

The hope is that, as a result of the research, the next high-rise using the system will be more refined in its design and more efficient and economical, says Klemencic.