The Rueter-Hess Water Purification Facility (RHWPF), located in Parker, Colo., southeast of Denver, celebrated its grand opening in late October. The water treatment plant, which serves a community of approximately 50,000 residents, uses new technologies that have enabled the owner—Parker Water and Sanitation District (PWSD)—to convert from rapidly declining groundwater sources to a renewable water supply, including surface water, groundwater, alluvial well water and reclaimed wastewater.

Designed by Dewberry, the RHWPF is the first plant in the world to incorporate a trio of cutting-edge technologies to meet EPA drinking water standards, according to the designer. The process includes three key stages:

- A coagulation, flocculation and sedimentation chamber that uses micro-sand to enhance particle sedimentation while reducing the chamber’s surface-area requirements.

- A recirculating powdered activated carbon (PAC) chamber that cuts costs by sending used PAC back through the system, increasing the amount of contact time between PAC particles and dissolved organic compounds for a more aggressive and efficient treatment.

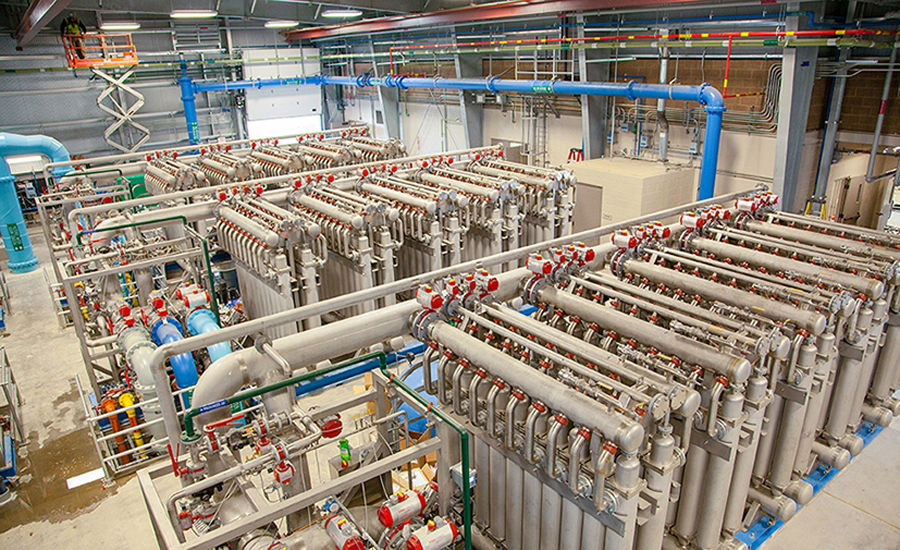

- Treated water that is then pumped through ceramic membrane filters to remove remaining particles larger than 0.1 microns in size and any remaining micro-sand or PAC.

In the first-such application in a drinking water system in the U.S., the 600 ceramic-membrane modules were specifically chosen for their ability to withstand impacts from the abrasive sand and PAC particles used in upstream processes and then be cleaned back to like-new condition. The ceramic membrane filtration system is anticipated to last much longer than conventional polymeric membranes.

“The ceramic membranes are very durable and can withstand impacts from sand and powdered activated carbon, which is very abrasive,” said Alan Pratt, Dewberry design project manager for the RHWPF. “The ceramic membranes can be cleaned back to a new condition, whereas polymeric membranes typically deteriorate over a life of six to 10 years and need to be replaced.”

Multiple Phases

The completion of the 10-mgd RHWPF (expandable to 40 mgd) is part of a multi-phase plan for the water district, where district leaders had long recognized groundwater as a diminishing resource within the rapidly developing area. The new network features a 50-cfs pump station that brings surface water from nearby Cherry Creek and Cherry Creek alluvial wells into the 75,000-acre-ft Rueter-Hess Reservoir, completed in 2012. Water stored in the reservoir flows by gravity into the RHWPF.

After moving through the two ballasted sedimentation chambers and the ceramic membrane filters, the disinfected water is pumped into the PWSD through a distribution-piping network for use by customers. Wastewater is returned to nearby reclamation facilities and then to Cherry Creek for reuse.

In addition to Dewberry, the project team included Western Summit Constructors Inc. as the primary contractor, Garney-Weaver for construction management and Kruger Inc. for the ballasted sedimentation and ceramic membrane-filter technologies.

“The ability for us to turn many different water qualities into a high-quality potable water supply has been made possible only with the combined effort of many different companies coming together,” said PWSD District Manager Ron Redd. “Dewberry, Western Summit and Kruger have all worked very hard to make this plant a reality.”