Vineyard Commuter Rail Station

Vineyard, Utah

BEST PROJECT

Submitted By: Stacy and Witbeck Inc.

Owner: Utah Dept. of Transportation

Lead Design Firm: HW Lochner Inc.

General Contractor: Stacy and Witbeck Inc.

Systems and Communications Subcontractor: Rocky Mountain Signal Systems

Subconsultant: CSRA

The project added a new station to the existing FrontRunner commuter rail system, which shares a corridor with the Union Pacific Railroad (UPRR) freight main line. The station provides commuter rail access for residents of the growing city of Vineyard. The design incorporates elements identified by the city—a nearby lake, a former steel mill, the city’s railroad history—which are displayed on glass panels that connect to the canopies protecting commuters from the elements.

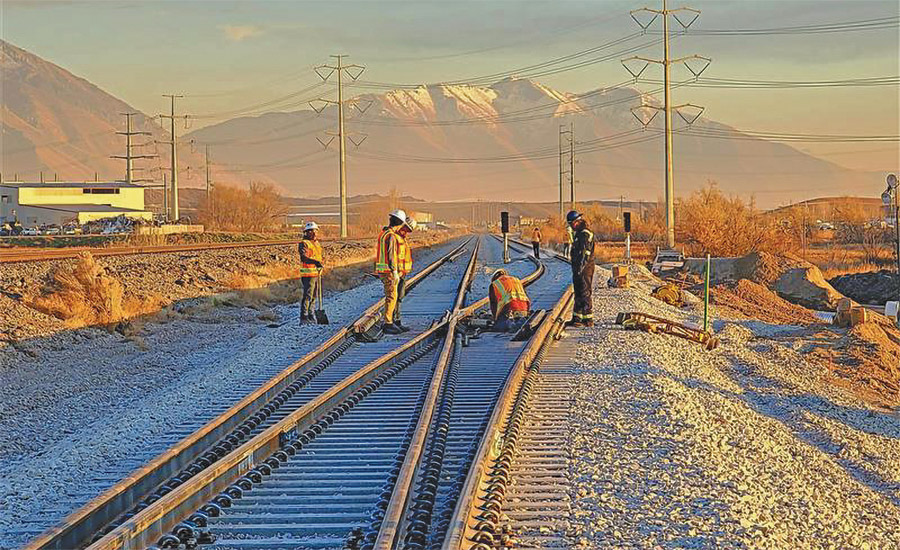

The project was built concurrently with a master-planned mixed-used development in downtown Vineyard that includes walking and bicycle access to the station. The station is the first to double-track rails on the 90-mile FrontRunner system to help facilitate efficient operations and route schedules. The project scope included earthwork, the addition of a new platform and canopies, nearly two miles of new ballasted track adjacent to the existing main line, along with a new number 24 turnout. Station amenities include a hydronic system that pumps a mixture of glycol and hot water to melt snow and ice during winter months.

Photo by Mike Brown, courtesy Stacy and Witbeck Inc.

The Utah Transit Authority (UTA) built the foundation for the platform for the station during the construction of the initial FrontRunner project in 2012, which saved time and money for the station addition. Construction occurred on a shared corridor where UPRR had as many as 40 trains a day running at speeds up to 79 miles per hour. This ongoing activity required coordination with multiple stakeholders to coordinate train movements and minimize downtime for construction operations. A team of 40 people completed the project’s most complicated operation over the Thanksgiving holiday—the installation of the new number 24 turnout and the signal system commissioning, including positive train control during an eight-day shutdown. The team completed this around-the-clock operation 12 hours early.

The project is the first UTA platform to use a rubber gap filler technology at the edge of the station platform. The 915 linear ft of filler improves safety by bridging the gap from the platform to the train, preventing injuries from falls as well as improving ADA access.

Photo by Mike Brown, courtesy Stacy and Witbeck Inc.

The project team navigated a complex relationship between the Utah Dept. of Transportation (UDOT) and the UTA, the agency operating the commuter rail. The contractual relationship placed project management responsibilities with UDOT, whose staff was less familiar with rail construction and operations. The team made establishing clear communication channels a priority, creating an atmosphere where all parties were comfortable asking questions and discussing concerns.

Photo by Mike Brown, courtesy Stacy and Witbeck Inc.

Regular site walks with quality inspectors were key to meeting quality expectations and contract requirements. Test trains were used to demonstrate how the train cars would react traveling at different speeds through the newly installed track during multiple phases of the inspection process. All testing was performed in partnership with UDOT and UTA.