Nearly a decade ago, early in conceptual design for the 230,000-sq-ft infill addition to the American Museum of Natural History in Manhattan, talks with potential contractors made it apparent that conventional rigid formwork for the undulating and nonrepetitive interior bearing walls—designed in concrete to evoke an 80-ft-tall canyon—would be prohibitively expensive and wasteful.

“Concrete is fluid but formwork isn’t,” said Jeanne Gang, founding principal and a partner of design architect Studio Gang, after a briefing April 26 at the museum's $465-million Richard Gilder Center for Science, Education and Innovation, set to open May 4. “The barrier to curves is often the formwork,” added Gang.

The design team soon found a better way to shape the myriad curves of the six-story atrium lobby. According to Gang, during brainstorming sessions, project structural engineer Arup said, “What about shotcrete?”

A trip to see work-in-progress on the arched shotcrete walls of Manhattan’s East Side Access rail tunnel followed. Gang was sold on the method.

The bearing walls of the lobby atrium, designed to evoke a canyon, presented complexities for the design and construction team thanks to the amorphous forms.

Photo by Nadine M. Post/ENR

“I saw with my own two eyes” the potential for shotcrete walls to shape the canyon, she says, adding that shotcrete also lent itself to expressing the canyon structure and the “skill and craft of the people who made it.”

There is no argument that shotcrete—concrete slurry under pressure sprayed onto reinforcing steel backed by dense metal mesh—was a simpler solution than rigid formwork for the six levels of description-defying curvilinear bearing walls that surround the 468,000-cu-ft skylit atrium.

But the team charged with realizing the landscape—complete with nonrectilinear “stone” bridges across the volume at two levels and amorphous “cave entrances” into the conventional building—found itself between a rock and a hard place. Not only are the canyon walls literally off the grid, there is no repetition in the shotcrete structure. There also was no precedent for an architecturally expressed asymmetrical shotcrete structure on such a scale.

So the team pulled all the stops—including 3D modeling every single bar in the undulating walls as well as modeling the extensive temporary works required for construction.

The shotcrete structure, fabricated and built by COST of Wisconsin under a design-assist contract, drove the project but “it wasn’t easy,” says Carla Sciara, an executive vice president of AECOM Tishman, the construction manager. It was so demanding that Tishman had three staff on site daily, simply to monitor the operation to ensure quality.

The original project budget was $383 million. The museum attributes the $82-million cost increase to construction escalation, resolved litigation relating to the encroachment of the building on the surrounding park, and the impacts of COVID-19, including supply chain disruption. Funding is from city, state and private sources, including from donor Richard Gilder.

The 230,000-sq-ft building, designed by Studio Gang with Davis Brody Bond as executive architect, consists of a 190,000-sq-ft addition and 40,000 sq ft of existing-museum renovated space. Gilder creates 33 connections to 10 existing museum buildings, some of which date to 1874. That removed dead ends in the museum tour, which improves circulation and the visitor experience, says Gang.

Three buildings were removed for the project. That allowed about 80% of the addition to be located within the footprint of the existing museum. And that translated to intruding on only 11,600 sq ft of the 18-acre campus’ Theodore Roosevelt Park, says the museum.

Among the new galleries and exhibits are a 5,000-sq-ft insectarium, a 2,500-sq-ft butterfly vivarium, a 5,800-sq-ft immersive theater, a restaurant, a museum shop, and a library and learning center. But the visual attention-getter of the design—and the toughest nut to crack for the team—is the canyon.

The interior shotcrete walls of the reinforced concrete structure, with flat-plate floor slabs, range from 6 in. to 14 in. in thickness. The walls have amorphous openings for circulation into the building’s corridors and rooms.

The perimeter of the tucked-in new building, except for the west-entrance shotcrete wall, has ordinary concrete columns. The structure of the undulating west wall, which supports Milford pink granite panels set in a diagonal pattern and the windows—with fritted glass to thwart bird collisions—is also shotcrete but is only exposed on the interior face.

Shotcrete is often used for curved shapes for it needs no rigid formwork. For the Gilder Center's bearing walls, the material was applied under pressure to the curved rebar.

Photo courtesy of AMNH / D. Finnin

Shotcrete is an up-close method of applying wet concrete projected at high velocity. The mix is pumped through a hose onto a receiving surface, according to the American Concrete Institute. The impact created by the application consolidates the concrete.

Though the hardened properties of shotcrete are similar to those of conventional cast-in-place concrete, “the nature of the placement process results in an excellent bond with most substrates, and rapid or instant capabilities, particularly on complex forms or shapes,” says ACI.

Shotcrete is commonly used for nonrectilinear forms, such as exhibits in museums, theme parks and zoos. Taxidermist Carl Akeley invented the application method, first called gunite, in 1907, a couple years before he began working at the American Museum of Natural History, according to the museum and history books. The first application was a plaster mix used to repair the crumbling façade of the Field Museum of Natural History in Chicago.

Shotcrete dispenses with conventional two-sided rigid formwork. Instead, a flexible dense metal mesh—which stays in place after the shoot—serves as a backdrop to keep the shotcrete from spilling out the back face as it is “shot.” At the museum, reinforcing steel shapes the wall, in essence serving as the form.

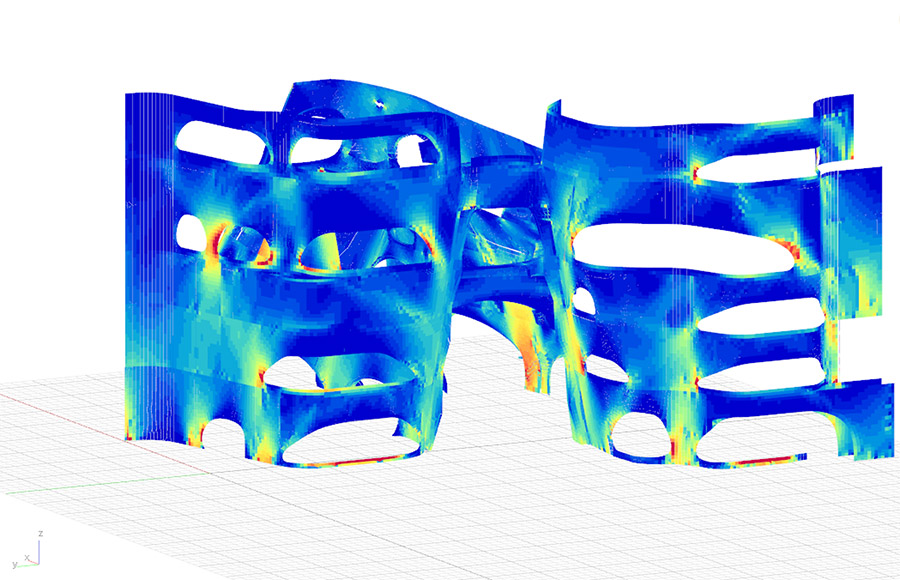

Structural design of the canyon walls was complicated by the need to find load paths to only six main touchdown points, thanks to an existing service yard directly below the building. The analysis of the shotcrete bearing walls that form the canyon show the two bridges (center of model) that span the atrium.

Structural analysis model of canyon walls courtesy Arup

Crews first built the conventional reinforced concrete perimeter columns around three sides of the building, followed by flat-plate floor slabs, also conventionally built except they temporarily spanned from the perimeter structure to falsework before the shotcrete walls were in place.

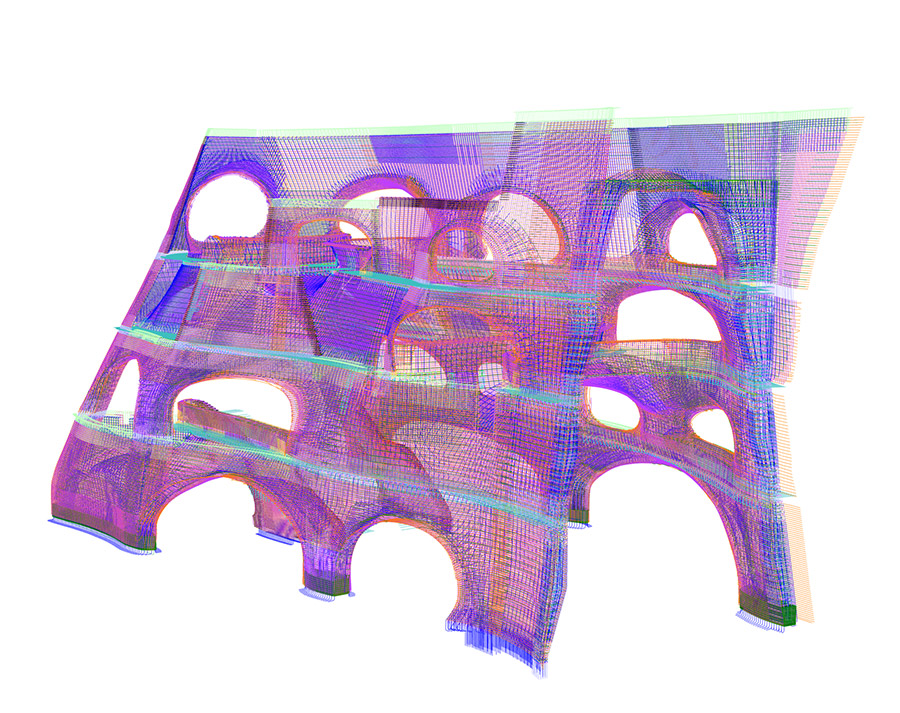

The construction manager had the temporary works modeled in 3D, which is not typical, says Michelle Roelofs, Arup’s associate principal. Arup then overlayed the temporary works model on its own 3D models for the overall structure and for the canyon wall rebar.

Arup modeled every single piece of rebar in the canyon walls.

Canyon wall rebar model courtesy Arup

The canyon work overshadowed the project. But there were other issues. A major impediment was the site. The building, about 250 ft x 200 ft in plan, sits on the underground service yard replete with active utility runs and the loading dock for the entire 18-acre campus, which remained open during the four years of construction. All building systems had to remain operational.

AECOM Tishman knew from the start that delicate hand-digging, rather than excavators and earth movers, would be required in certain areas to mitigate the risk of damaging sewer pipes, power lines and other utility runs. “It was almost as if we were doing salvage rather than demolition,” says Sciara.

The basement conditions also tied the hands of the structural engineer, for they limited locations for the canyon wall basement columns and their foundations to six main points, says Roelofs.

After hand-drawing the load paths, Arup ran its own 3D model, using a 3D geometry model generated by Studio Gang, and converted that to the structural analysis model. “It was a push and pull” during design to locate the wall openings and canyon bridges based on programmatic needs and still create logical load paths to the touchdown points, says Roelofs. “The shear act of modeling was a technical challenge,” she adds.

The layout of the canyon reinforcing steel, which serves as the form for the amorphous contours, required applying coordinate geometry. Many of the bars had to be prebent. Tolerances were tight for wall embeds both to receive the flat-plate floors and to hang the granite exterior cladding panels.

COST of Wisconsin prefabricated the rebar cages for the west entrance wall at its plant but conventionally installed rebar for the canyon walls.

For the walls, the first major step on site was the installation of vertical pipe forms, following the general contours of the future walls, to guide the landing path of the prefabricated rebar cages. Crews hung the pipe forms, which spanned from floor to floor, off the bottom of the slab above or set them on the floor below.

Each pipe form was surveyed into an exact position. Pipes, spaced every foot or two, had standoffs—welded threaded nuts, each color-coded to assign it to a similarly coded bolt on a rebar cage.

Crews attached the metal mesh “back splash” to the standoffs and then the rebar—also precisely laid out to shape the geometry. Every bar was individually labeled and tagged to go in a certain location.

A certified nozzleman then followed with the gray layer of shotcrete, starting at the base. There was no typical sprayed section. Size varied on the complexity of the section, from 5 ft to 20 ft in length, though height of a lift was typically 8 ft. Depth also varied.

Curtain wall panels are hung from embeds set in the shotcrete of the curved exterior wall of the addition, set between existing buildings.

Photo courtesy AMNH

Work on the gray layer started at the base and proceeded up to the top of the building. Crews started on the white finish coat at the top and worked their way down.

The gray layer was designed to support the building in the temporary condition, under construction loads, so that shoring could be removed.

There were two crews working on the shotcrete, says AECOM Tishman. The rebar had to be enveloped by a 1/2-in. thick cover of gray material.

During construction of the two bridges that span the atrium, temporary steel beams supported the weight of the shotcrete. The sequence of bridge construction was steel beams, rebar, shotcrete and beam removal.

The shotcrete operation was complicated by the cold weather and the need to heat the work area so the concrete could cure properly. The structural walls took about 30 days to cure.

There were no control joints required, says Arup. But COST of Wisconsin had to work out the cold joints for the architectural white layer with the architect, which did not want vertical or horizontal seams to interfere with the natural look.

COST had planned to begin the wall construction, including pipes, rebar and the gray layer, on the north side of the atrium space at level one and work to the south side, moving in a corkscrew fashion up the building before coming down with the white finish coat. But mostly, the shotcrete followed the complex rebar installation, which drove the schedule. The canyon walls contain 453 tons of rebar.

Workers accessed the space through a temporary platform in the atrium void, called a dance floor, and other means. Each shoot was 5 cu yd to 50 cu yd, depending on what was available.

General construction started in the spring of 2019. Prior to that the museum and AECOM Tishman worked for more than two years to clear the site and/or reroute, where necessary, “live” critical infrastructure from the museum’s service yard.

Excavation and foundation work started in May 2019 and wrapped up in October 2020. But there was a construction suspension for about 4-1/2 months, from mid-March through mid-August 2020, due to COVID-19. There were other COVID-19 delays to the project related to interrupted supply lines, but none of that completely suspended construction, according to the museum.

Conventional superstructure concrete, including perimeter columns, and slabs supported by temporary deck and dynamic shoring for the slab ends prior to the structural shotcrete installation, took place from September 2020 to April 2021.

Crews then installed the pipes and rebar for the shotcrete walls, followed by the structural layer, from April 2021 until last September. When that was complete, crews removed the dynamic shoring for the slabs. Then, working from the top down, they shot the white shotcrete layer, which was trowel finished.

From November 2021 until last December, workers built the curtain wall. As of January 2021, the building was closed in and weather tight, says the museum. Substantial completion was last month, including most fit-out work.

In the minds of the design and construction team, though there were myriad challenges, the shotcrete operation is imprinted as the most difficult. All the constraints were known at bid time, says AECOM Tishman’s Sciara. She adds, “We knew about the impediments in advance and worked them into the schedule.”

Editor's note: This article was updated on May 5.