Hyperion Headworks Odor Control Upgrade

Los Angeles

BEST PROJECT

Submitted by: City of Los Angeles Bureau of Engineering

Owner/Lead Design Firm: City of Los Angeles Bureau of Engineering

General Contractor: Murray Company Mechanical Contractors

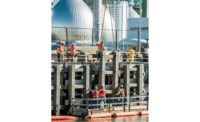

To significantly improve air quality and reduce odor emissions at the Hyperion Water Reclamation Plant, crews replaced outdated odor control equipment with advanced technologies, specifically four biotrickling filters (BTFs) and eight carbon scrubbers to effectively remove hydrogen sulfide and foul-smelling gasses from the influent sewer and headworks areas.

The BTFs utilize biological processes to break down hydrogen sulfide and other pollutants in a sustainable and environmentally friendly manner. This approach enhances odor removal effectiveness and reduces reliance on hazardous chemicals, promoting a safer working environment for plant operators.

Additionally, the eight new carbon scrubbers use activated carbon to adsorb and remove residual odorous compounds, ensuring the treated air released into the environment is virtually odor free. The integration of BTFs and carbon scrubbers creates a robust odor control system capable of handling varying levels of odorous emissions.

by Kenneth Frere

The extracted gasses from the influent sewer and headworks will be treated sequentially through the BTF system and activated carbon units, ensuring maximum efficiency in odor removal and mitigating potential impacts on the surrounding community. Scope also included installing advanced monitoring and control systems to continuously assess the performance of the odor control equipment, allowing for real-time adjustments and optimization.

During construction, a major flooding event threatened to derail the team’s progress. From the onset, the flood created a chaotic and high-pressure environment. The first priority was ensuring the safety of all personnel. Clear and consistent updates were crucial as crews coordinated efforts to evacuate nonessential staff and secure sensitive equipment. The rapid response highlighted the importance of having a well-prepared emergency protocol and a team that could execute it flawlessly.

The focus then shifted to recovery and construction restart. As the waters receded, the facility not only returned to its original operational state but also incorporated enhancements made during the flood that made it better able to withstand future events.