Installing a new headworks at an existing wastewater treatment plant is much like trying to perform a head transplant while keeping the patient alive, says Jignesh Desai, senior project manager of the project management bureau at the San Francisco Public Utilities Commission (SFPUC). But that’s exactly what’s happening at the utility’s Southeast Treatment Plant (SEP), which was first built in 1952 and is the largest of the city’s three treatment facilities.

A $718-million effort is replacing SEP’s two existing headworks—a 150-million-gallon-per-day dry weather headworks and a 100-mgd wet weather headworks—with a consolidated all-weather 250-mgd headworks facility that has improved performance, seismic reliability and operational flexibility, Desai says.

As part of the first stage of wastewater treatment, a headworks removes debris and grit from the flow, preventing damage to critical downstream equipment.

This project is just one part of a more than $3-billion investment in modernizing the SEP. The new headworks will better protect downstream processes and equipment and reduce operation and maintenance requirements. It is designed to withstand up to a 7.8 earthquake and anticipated sea level rise of 36 in. by 2100.

However, the new headworks facility required some creativity to fit the scope within a limited footprint while ensuring wastewater treatment operations could continued uninterrupted throughout construction.

The odor control system consists of biotrickling filters and carbon absorbers to eliminate waste odors from the headworks building. Clean air is then released into the atmosphere at the end of the odor cleansing process.

Photo courtesy of Sundt

Years in the Making

A combined sewer system spanning more than 1,000 miles and three treatment plants serve the city and county of San Francisco, treating an average of 40 billion gallons of wastewater and stormwater each year.

Back in 2012, the SFPUC, the third-largest public utility in California with a current wastewater capital program portfolio of more than $6.8 billion, endorsed Levels of Service Goals under its sewer system improvement program—a 20-year, multibillion-dollar citywide effort to upgrade aging sewer infrastructure.

“The major challenges on this job were keeping the plant operational and building such a large facility in a really small footprint.”

—Sam Reidy, President, Water & Wastewater, Sundt Construction

For the SEP headworks, “we brought on design consultant Carollo Engineers in 2016 to help SFPUC complete the planning phase, resulting in a conceptual engineering report and support for the subsequent design phase,” Desai says. Under a construction manager/general contractor (CMGC) contract, “we onboarded the Sundt/Walsh joint venture in 2017 to provide constructibility support during the detail design phase and to construct the 250-mgd facility,” he adds.

CMGC allowed for the contractor and core trade partners to collaborate early with SFPUC and the design team. Preconstruction efforts ranged from constructibility reviews and real-time cost estimates, which resulted in a major redesign and cost savings, says Sam Reidy, president of water and wastewater at Sundt.

“SFPUC has used traditional design-bid-build delivery methods, however, and in the last decade, we have started using alternative delivery methods,” Desai says.

The Southeast Treatment Plant’s headworks is designed to treat both sanitary and stormwater flows and provide better screenings and grit removal to protect downstream equipment. It was designed and built to fit within a 31,500-sq-ft site.

Image courtesy of Carollo Engineers

Demo to Build

SEP is situated right in the middle of a mixed industrial, commercial and residential area, with some homes located just across the street.

“The major challenges on this job were keeping the plant operational and building such a large facility in a really small footprint and allowing operators access to the surrounding facilities. This required a lot of coordination with engineers and plant operations staff,” Reidy says. “There’s not a lot of laydown space, so it was build something to tear something down to build something else.”

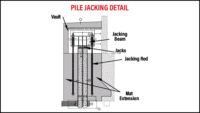

To that end, work is being delivered across three phases. First, the team prepared the site, demolished the existing dry weather headworks and installed in its footprint a temporary 100-mgd bypass. This allowed for demolition of the wet weather headworks. Second, crews completed upgrades on the Bruce Flynn 150-mgd wet weather pump station located across the street from SEP.

The third phase saw construction begin on the 50-mgd SEP 008 influent pump station—which will move sewage from local sewers to the influent junction at the new headworks—and the all-weather headworks facility itself. For the SEP 008, crews replaced everything mechanical and electrical within the station, modifying it from a dry pit pump station to a pump station that utilizes submersible pumps in the wet pits, Reidy says.

Meanwhile, a large-scale odor control facility was relocated to another space on the site, allowing the team to refurbish an existing pump station while also drastically reducing smells. “There had been complaints from the surrounding public, so the client made a significant investment in odor control technologies,” Reidy adds.

At just 31,500 sq ft, the site presented multiple logistical challenges. It’s also bordered by transportation corridors to the east and north, with other process buildings both south and west.

This made coordination critical; stakeholders—from neighboring businesses to plant operations crews, subcontractors and Union Pacific Railroad—were closely involved and aware of construction activities. The team prepared maintenance plan operations with hour-by-hour schedules if construction was expected to affect plant operations and utilized daily subcontractor meetings and a last planner system to offer one- to six-week look-aheads.

Because some work occurred along the property line and adjacent railroad tracks, the project team had to obtain special permitting, utilize third-party flagging and plan work around scheduled train times, Reidy says.

The grit gallery is where grit pumps and appurtenances collect grit and pump it downstream for removal. This equipment is currently going through operational testing.

Photo courtesy of Sundt

Building Upward

Not only does SEP treat about 80% of the wastewater for the city and surrounding areas, but it also handles both sanitary and stormwater flows, explains Jim Hagstrom, executive vice president and managing director of technical practices at Carollo Engineers. Such a combined system means there are high flow variations—on average, the plant treats about 80 mgd, but that flow can go as high as 250 mgd during storms.

One of the ways to mitigate such a wide range of potential flows is by having large storage capacity in the collection system, “but that allows a tremendous amount of grit to be retained,” Hagstrom says.

Peak grit loads at SEP can exceed 6,000 lb/mg—nearly two times the industry standard, Desai adds.

Meanwhile, construction is also underway on biosolids digester facilities downstream of the headworks, set for 2028 completion, with very strict limits on grit content.

“Instead of adding more screens, we actually changed the water level.”

—Jim Hagstrom, Executive Vice President, Managing Director, Technical Practices, Carollo Engineers

“The challenge is you’ve got these high flow variations, really high grit loads because it’s a combined system, and the performance has to be higher than most wastewater treatment plants because of the biosolids system that they are putting downstream,” Hagstrom says. “So you have to have really good grit removal or high efficiency grit removal from the headworks component.”

To figure out which technologies would be best for the headworks, SFPUC conducted a full-scale, side-by-side 5-mgd pilot to test different grit separation and grit washing technologies.

“We selected the head cell for grit removal that provides a much higher level of grit removal than the typical industry standard,” Hagstrom says. “Then we take that grit and we wash it to reduce both odors and the overall weight that gets hauled away.”

Another challenge was finding a way to install an appropriate amount of screening, given the site’s constraints.

“Instead of adding more screens, we actually changed the water level. So under high flow conditions, we increase the hydraulic grade line through the screen so that we don’t get too high a velocity through them,” Hagstrom says. “What limits effective screening is velocity through the screen. As the velocity goes up, you have to add more screens. But we didn’t have that luxury, given the footprint, so we added depth.”

Instead of the eight screen channels specified in the original concept, the team installed just four screens that complete the same work by simply using hydraulics. “I think that’s probably one of the most unique things that we did on the headworks to try to fit it on the site,” he says.

Vertical construction and stacking processes proved a vital solution in other areas as well, from odor control to grit washing and handling and electrical support facilities, ensuring installation of these vital elements while staying within the site lines.

A top view of the grit tanks under construction. Gates will control flow into the grit tank chambers when the plant is operational. Crews also applied coatings to protect the concrete within the tanks and chambers.

Photo courtesy of Sundt

Critical Impacts

Improved aesthetics at SEP are helping the facility be a better neighbor throughout construction and beyond. Since 2020, four temporary public art installations have been featured on construction safety fencing, while a permanent 335-ft-long by 35-ft-high mural was recently installed, referencing the headworks treatment process.

Since LEED certification wasn’t quite the right fit for this type of facility, the design team suggested to SFPUC that Envision, designated by the Institute for Sustainable Infrastructure, would be a better fit, Hagstrom adds. In addition to being the first project the city of San Francisco has implemented with Envision, the headworks also recently won an Envision Gold award.

Construction is nearing completion and start-up was underway in late August. The project is within budget and substantial completion is on track for December, with final completion set for May 2025.

“The headworks project will be a critical element in achieving SFPUC’s commitment to protecting public health in our community,” Desai says.