"By using only half the normal reeving, it allowed us the additional wire rope necessary to increase the below-grade capabilities while still maintaining the same drum capacity," says Jerry Studer, Mi-Jack's Southeast sales manager. He estimates the firm manufactures less than a dozen gantry units of any size per year for highway work, making this project unusual in more than one way.

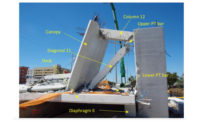

Occasionally, the cranes have worked together. On August 7, crews performed tandem picks of six 84-ft-long precast concrete beams weighing roughly 69,000 lb each. Though each crane can lift up to 92,000 lb, other factors dictated using both cranes.

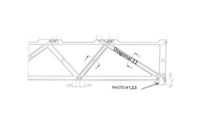

First, the method reduced the direct loads to the cranes, their rubber tires and the bridge structures by distributing the beam load across multiple spans. Picking the beams with a single crane would have required installing a spreader bar, while a tandem pick required no below-the-hook modifications.

"There's not much rigging involved," Savage says. "There's just one hook [on each crane] and a 55-ton shackle that screws right into the beam [at each end]— no other slings or anything else."

Quick Picks

Within a couple of minutes during the tandem lifts, each crane operator had his respective hook connected to the shackle and lifted the beam up close to the units' 25-ft, 5-in. maximum hook height, to minimize load sway. Once both cranes drove onto the bridge structure, the operators only needed to concentrate on keeping the units moving in sync. GPS handled the rest.

The units were speedy, too. The contractor estimated three hours to place the six beams, but crews completed the work in two and a half, Savage says.