Home » 3d printing

Articles Tagged with ''3d printing''

Design

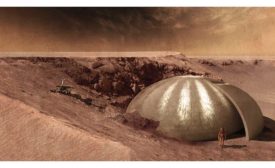

Office Built Out of 3D-Printed Components Opens in Dubai

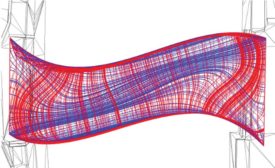

Demonstration Project Tests New Large-Scale 3D Printing Process

Read More

ENR FutureTech Shines With Innovations

Annual construction technology conference in San Francisco crackles with new ideas, advice, cautions and optimism

Read More

The latest news and information

#1 Source for Construction News, Data, Rankings, Analysis, and Commentary

JOIN ENR UNLIMITEDCopyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing