Dynamics Duo Gives Forward Push to Giant Kinetic Structures

|

| SILBERMAN |

Self-anointed professional dreamer Cyril J. Silberman and grounded structural engineer Lawrence G. Griffis prove opposites can attract. They have become a duo of dynamic roofs—and walls and playing fields—in sports construction. In a decade, they have collaborated on a half-dozen projects in the U.S. and chased several dozen in places as far flung as China. In doing so, they have helped thrust kinetic stadium architecture forward.

“We started with simple horizontal motion, then got brave going with mild slopes and now the slopes are getting steeper,” says Griffis, senior principal in the Austin office of Walter P Moore.

|

Silberman’s dream is to change the direction of rolling roofs from biparting panels rolling on parallel rails set on high structure to a sloped wall-roof assembly that slides, like a pocket door, level and sideways on a grade beam. For a decade, Silberman, CEO of kinetic architecture supplier Uni-Systems LLC, Minneapolis, has been spinning his wheels seeking a taker for his down-to-earth scheme, which he claims would offer 75% of the roof opening size for 50% of the cost of high-rolling panels, which rely on heavier, less-constructible structure. Sloped systems also need more complicated drives, such as cable-drum “yo-yos” and rack-and-pinion “tractors.”

| + click to enlarge |

Uni-Systems

|

| + click to enlarge |

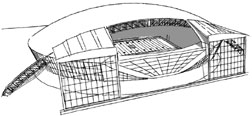

Manhattan Construction Wall-roof assembly (top) would ride on grade beam, easing construction and reducing steel tonnage and cost. Cowboys job (bottom) uses first rack-and-pinion drive.

|

Griffis greets Silberman’s vision with characteristic pragmatism. It might be useful in cold climes because, with the right angle, snow would slide off, thereby reducing snow loads. But the trade-off is that the required 250-ft height would increase wind loads, says Griffis.

Silberman is not letting grass grow underfoot until his giant door finds a home. WPM and Uni-Systems have already collaborated on three completed facilities with rolling roofs, all done on time and budget. In 2000, a ballpark for the Houston Astros opened. Next, in 2002, came Houston’s Reliant Stadium. A venue for football’s Arizona Cardinals—the first with a retractable field—followed. The team’s first project with movable roof panels and a retractable, glass end-zone wall opens next month in Indianapolis for football’s Colts. And a venue for the Dallas Cowboys, with the first rack-and-pinion drive and the steepest slope so far, plus the two biggest retractable-glass end-zone walls, is to open a year later.

Indiana Stadium & Convention Bld Authority |

Tish Cowan Photography |

Colts stadium is first with panels sliding down pitched roof (left). Houston ballpark was first for Griffis-Silberman team. | |

|

| GRIFFIS |

WPM and Uni-Systems see improvements to rolling roofs through folding fabrics such as high-strength expanded polytetrafluoroethylene. Its light weight reduces the massive support structures. High-strength structural steel also is on the horizon, which would reduce weight and effective loads, along with mechanization costs.

Griffis dreams about portable systems that could be dismantled and stored. That would likely free the structure to be designed to resist operating wind loads rather than the 100-year windstorm.

Walter P Moore / John Aniol Cowboys’ stadium panels will roll on tracks along parallel arches that rise 292 ft. Silberman wants to bring tracks down to earth.

|

Tensegrity cable roof structures, more common outside of the U.S., would allow lighter and more economical structural systems. But there is a bias against cable structures among most U.S. builders of sports facilities, says Griffis. “We hope to change that,” he says.

WPM and Uni-Systems haven’t stopped with back-and-forth motion or with sports work. If all goes well, the duo’s first occupied ride a 400-ft-dia Ferris wheel for Orlando will start spinning in 2010.

Related Links:

Related Links: