5. For a local university law school project, our project team is utilizing BIM for energy modeling to verify Title 24 and ASHRAE 90 baseline calculations. In addition, facilities management will use BIM and the integrated building control system (i.e., HVAC, ceiling fans, operable windows, shade controls, lighting, etc. to “fine-tune” energy performance results, based upon trend data.) The projected BIM savings per year is nearly 15%.

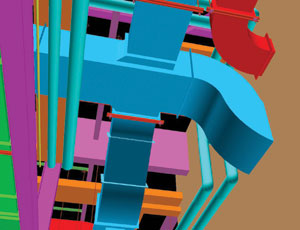

6. During a biotech manufacturing expansion project, we used the BIM animation feature for equipment setting, given the limited space constraints. Mechanical, process piping, plumbing, electrical and fire protection scopes of work were coordinated using Autodesk Navisworks 2010. The resource-loaded scheduling approach for MEP rough-in phase was based on BIM model information.

7. For a biotech pilot plant project, we used BIM to coordinate a new structural roof platform vs. the air handling units and process air handling units to ensure proper access was achieved and unnecessary piping and ductwork offsets were avoided, causing pressure drops and increased energy consumption. And we used BIM for air filtration, specifically HEPA filter location for air flow characteristics vs. process equipment and user interface.

8. For a biotech isolator/scale-up project, we used BIM for a Class 100 or Grade A room to ensure proper air flow was maintained throughout the space vs. process equipment. In addition, this model was used for mechanical, plumbing and electrical/controls interface, given the limited building height.

9. On a biotech project we were able to use the model to expedite the design and fabrication process by using the model to finalize appropriate routings in highly complex spaces and move directly into fabrication of all duct and piping materials. The model allows for direct usage in creating validation documentation (ISOs, weld logs, etc.) and to bypass lengthy reviews of individual isometric drawings.

10. On a local university project, the BIM model provided for a detailed review of the finished product to the client for verification that the design was satisfactory. We were also able to confirm the functionality of the private offices because our model integrated the ceiling fans, lighting, operable windows and control systems.

Overall, the advantages of using thoughtfully applied, smart building practices yield cost savings, as well as easier-to-access and more maintainable facilities, schedule reduction, improved accountability and better coordinated vendor management. BIM helps bring projects in on time and on budget much better than traditional paper-driven management methods of the past.

Melody Spradlin is a graduate of the U.S Naval Academy BS, Southern New Hampshire College MBA and Stanford University MS Civil Engineering, Construction Engineering and Management. Spradlin has worked in the construction industry since 1986 and in the Bay Area construction industry since 1988. She has taught in the Design Construction Integration masters program at Stanford University as a consulting professor and guest lecturer.

Post a comment to this article

Report Abusive Comment