Safety Product Engineers To Offer Contractors New Lineup of Finger-Saving Table Saws

|

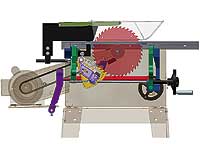

| SKIN DEEP Safety mechanism stops blades. (Illustration courtesy of Sawstop) |

After four years of promoting a clever safety device and failing to license it to power-tool makers, a small engineering team in Wilsonville, Ore., is entering the manufacturing business. It will start producing its own line of professional-grade table saws with a device that stops the blade instantaneously when it makes contact with flesh. They will be available next year.

"We will be competing with everyone else, but well have a feature that they dont have," says David Fulmer, electrical engineer, patent attorney and vice president of SawStop. The small-companys president, Steve Gass, a physicist and recreational woodworker, invented the SawStop safety mechanism in 1999. Two years later, the U.S. Consumer Product Safety Commission awarded a special commendation to the company, saying that more steps needed to be taken to prevent the more-than 30,000 hand and finger injuries from table and bench saws annually in the U.S.

Why major manufacturers refused to adopt the technology is unclear and they are not talking about it openly. SawStop believes that retooling costs and product liability concerns are the main objections. "They told us people do not want to pay any more for safety," says Fulmer, who estimates that the SawStop feature would add 15% to the cost of contractor saws.

The device operates by charging blades with 3 volts of alternating cur-rent. A sensor within the braking mechanism looks for fluctuations in the signal that occur when the saw strikes a conductive materiallike skin. In this event, the sensor activates a spring-loaded, aluminum pawl that stops saw teeth in about 5 milliseconds, leaving fingers only nicked. According to Fulmer, the devices only limitation is that SawStop can work only with wood and not metal.

![]()