Three ocean engineering firms in January completed testing of wave energy converters in a unique wind-wave test basin at the University of Maine, gauging how they will respond to severe offshore storms.

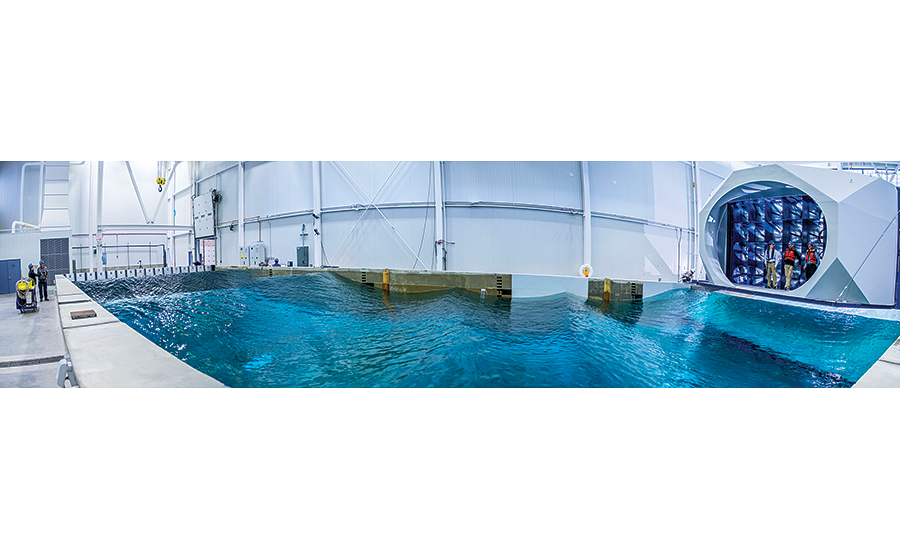

The Harold Alfond W2 Ocean Engineering Lab, which opened on Nov. 23, houses the world’s first offshore wind-wave test basin with a rotating open-jet wind tunnel over a multidirectional wave basin that mimics severe storms at sea, says Habib Dagher, director of the university’s

Advanced Structures and Composites Center (ASCC) in Orono. The 98-ft x 30-ft test basin uses 32 fans and 16 paddles to generate 100-plus-ft-equivalent waves and winds of more than 200 mph.

The 8,940-sq-ft W2 lab is one of five U.S. facilities selected to conduct 1:50-scale testing as part of the U.S. Dept. of Energy’s $2.25-million Wave Energy Prize competition. The 20-month design-build-test competition seeks to drive innovation in wave-energy devices through a rigorous testing program.

“Helping to identify the best ideas in the U.S. to convert wave energy into electricity is yet another way that UMaine participates in developing clean, low-cost, domestic renewable energy,” Dagher says.

In mid-December, RTI Wave Power, York, Maine, tested its sixth-generation 1:50-scale RTI F2 wave energy converter (WEC) at the lab. “The university’s wave-energy-prize test team ran 31 tests over two days to determine the capture efficiency of our device under varying wave conditions having up to 20 watts per meter of wave energy,” says John Rohrer, founder of RTI. “We’re comfortable our device performed as expected.” A DOE panel of judges will evaluate the 10 competition finalists in February and announce the results in March.

“We tested to see if our computational fluid-dynamics model was simulating what was actually happening with the device in the wave tank,” Rohrer adds. “It tested well, confirming our model.”

Oscilla Power, Seattle, and Float Inc.-BergerABAM, San Diego, also are testing WEC devices as part of the program led by Krish Thiagarajan, the university’s principal investigator on the project. “Additional projects are lined up, and inquiries are coming in daily,” says Josh Plourde, spokesman for ASCC.

The ocean engineering lab accurately simulates towing tests, accommodating water depths from zero to 16.4 ft, as well as scaled wind and wave conditions that represent some of the worst storms possible anywhere on earth, Plourde explains.

These capabilities will assist businesses worldwide in developing vessel hulls, wind and tidal energy generators, and deepwater aqua-culture technology, such as offshore fish holding pens with moorings. Other research areas comprise oil-and-gas structures, including those for seafloor extracting, and waterfront infrastructure— bridges, causeways, piers, docks and port facilities—that can withstand waves and scour. Scientists and engineers also will examine systems to protect coastal cities from the effects of erosion and extreme storms.

The lab will test bridge models for state departments of transportation, Dagher says. “This [lab] can assist engineering firms and city planning boards with future infrastructure plans,” he adds.

The attached, 3,725-sq-ft Advanced Manufacturing Lab for Structural Thermoplastics Composites, which Pittsfield, Maine-based Cianbro is constructing, is scheduled to open this summer. It will feature robotics and other equipment to study and develop thermoplastic composites. Crews have begun installing equipment, including the Stratysys Fortus 900 3D production system for printing accurate, repeatable parts as large as 914 x 610 x 914 millimeters (36 x 24 x 36 in.), Plourde says.

The W2 lab and the integrated Advanced Manufacturing Lab—both a part of the existing ASCC—were funded by a $5-million voter-approved bond and a $3.9-million grant from the Harold Alfond Foundation, along with nearly $10 million the university received from the U.S. Economic Development Administration, the National Science Foundation and the Maine Technology Institute, among others.