Using powerful nanotechnology tools, a research team led by the Massachusetts Institute of Technology has successfully modeled the complex structure of calcium silica hydrate (CSH), the main binding material in cement and concrete. Industry officials say this modeling could lead to more sustainable and durable concrete-mix designs.

In a paper published on Feb. 23 in the Proceedings of the National Academy of Sciences, researchers from MIT, Georgetown University, France’s CNRS and other universities in the U.S., France and the U.K. stated, “Our study delivers, for the first time, to our knowledge, a quantitative description of the meso-scale texture of CSH.”

Franz-Joseph Ulm, director of MIT’s Concrete Sustainability Hub (CSHub), Cambridge, and one of the paper’s 10 authors, says, “This [model] offers an opportunity to translate results from the fundamental scales of cement paste to the macro scale of concrete’s engineering properties.”

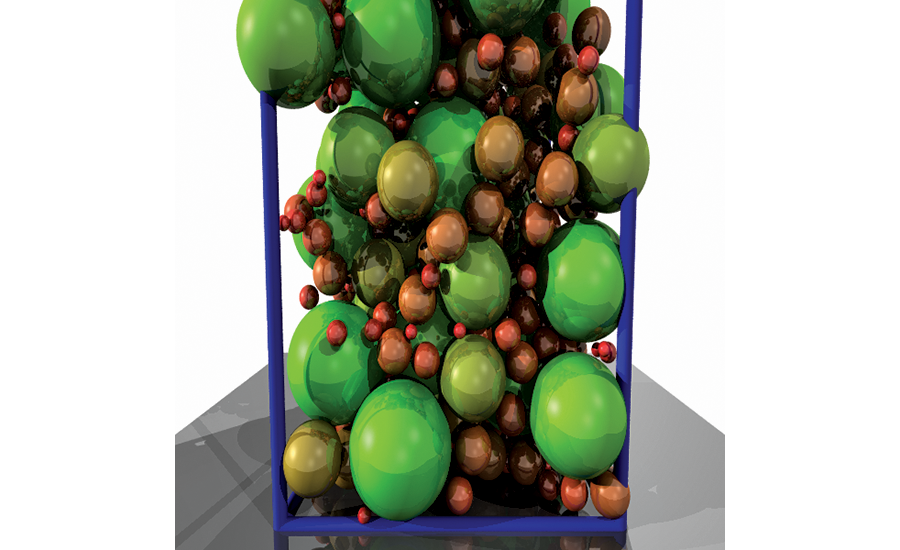

During investigations of different cement-paste specimens, the team said, “We used simulations that combine information of the nano-scale building units of CSH and their effective interactions, obtained from atomistic simulations and experiments, into a statistical physics framework for aggregating nanoparticles.”

“Small-angle neutron scattering, EM [electromagnetic] imaging, and mechanical nanoindentation experiments [to test hardness at the nano scale] all suggest [that] an even more important role may be played by the meso-scale organization of the CSH structure that extends over hundreds of nanometers,” the paper states.

Konstantin Sobolev, associate professor of civil engineering at the University of Wisconsin, Milwaukee, and chairman of the American Concrete Institute’s Nanotechnology Subcommittee 241, says that, until now, “the molecular structure of CSH was a mystery because we always thought it was amorphous CSH gel. We were not able to really quantify it.”

“Today, with AFM [atomic-force microscopy tools], we can prove that CSH has a nanocrystalline structure,” Sobolev says, adding that understanding the structure of the CSH gel increases the capability to manipulate and improve it.

Jim Toscas, CEO of the Portland Cement Association, says the modeling increases the potential to reduce the amount of heat and grinding energy required to produce cement and the overall environmental impact of manufacturing cement, a leading source of greenhouse-gas emissions.

This research builds on prior work that included, in collaboration with France’s CNRS, the first atomic-scale model of CSH at MIT’s CSHub. One key question was whether the solidified CSH material, comprising particles of many sizes, should be considered a continuous matrix or an assembly of discrete particles. The answer is a bit of both, since almost every space between grains is filled by yet smaller grains that approximate a continuous solid.

The analysis of the structure of hardened concrete found that pores of different sizes play a major role in determining how susceptible the material is to water infiltration, which can cause cracking and, eventually, structural failure. Using real concrete samples, the meso-scale simulations enable the values of key characteristics, such as stiffness, elasticity, and hardness, to be matched. This tactic could help to guide research on new formulas, including ones that reduce the required amount of water in the initial cement powder mix. Fine-tuning the amount of water also could improve the material’s durability, the researchers found.

As nanotechnology emerges from basic research, full-scale applications are still limited but eventually could include smart concrete, to provide early warning of structural deterioration at a lower cost than existing sensor systems; superhydrophobic concrete, which is extremely durable and repels water; and concrete with Si02 nanoparticles, to improve strength, Sobolev says.

Future use of nanomaterials and nanodesign, or the molecular design of material, could extend the durability of concrete buildings and infrastructure by a factor of five and service life by at least a factor of two, Toscas says. “The impact of MIT’s collaborative research could be enormous.”

In addition to MIT postdoctorate student Katerina Ioannidou, the lead researcher, the team included participants from MIT; the University of California at Los Angeles; Newcastle University, U.K.; Sorbonne University, Aix-Marseille University, and CNRS. The work was supported by Schlumberger and the French National Science Foundation (ANR) through Labex ICoME2, as well as the CSHub at MIT. Since its launch in 2009, CSHub has received $20 million from industry partners PCA and the Ready Mixed Concrete Research Education Foundation.