Water/Environment Best Project - Sutton Brook Disposal Area Superfund Site Remediation

Photo courtesy Charter Contracting Co. LLC

Photo courtesy Charter Contracting Co. LLC

Photo courtesy Charter Contracting Co. LLC

Photo courtesy Geosyntec Consultants

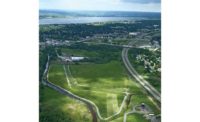

Sutton Brook Disposal Area Superfund Site Remediation

Tewksbury, Mass.

Best Project

Owner Engineering Management Inc.

Lead Design Firm Geosyntec Consultants

General Contractor Charter Contracting Co. LLC

Specialty Geotechnical Contractor Geo-Solutions Inc.

For three decades, municipal and industrial waste was dumped in the Sutton Brook Disposal Area Superfund Site. Waste material was burned, drum barrels were buried, debris and machinery were exposed and multiple contaminants and metals littered the 53-acre multilobe landfill.

The project team consolidated, capped and closed the landfill lobes while restoring surrounding wetlands and removing contamination from groundwater, sediments, soils and waterways. The team relocated and capped 39,415 cu yd of contaminated drum burial materials, reshaped and compacted 230,000 cu yd of aggregate and waste materials and installed almost 2 million sq ft of multilayer landfill cap.

To isolate groundwater contamination and remediate Sutton Brook, the team also built a nearly 60,000-sq-ft soil-bentonite slurry wall that was installed to a depth of 48 ft along the banks.

Additional water quality improvements included bypassing Sutton Brook to remove contaminated sediment. The team also installed a 37-ft precast culvert crossing, installed a groundwater extraction system with a new force main and discharge pipe, constructed nearly 90,000 sq ft of stormwater basins and treated 107,000 gallons of contaminated water.

The project’s schedule was maintained despite an access agreement issue that delayed mobilization by six months. Early issue identification revealed the slurry wall as a potential bottleneck. The project team developed a staging platform, soil support system and erosion controls that allowed long-reach equipment to safely achieve 48 ft depths while working along an active waterway with access from only one side. Working through weekends, the team accelerated slurry wall installation to maintain the schedule and allow landfill capping to continue unimpeded.

The project required installation of capping materials on sloped surfaces of two landfill lobes, including 270,000 tons of cover sand and 1,760,000 sq ft of geosynthetic clay liner on each geomembrane. A series of drainage benches and down chutes directed stormwater runoff through designated flow areas into lined stormwater basins. Water bars were also installed to control and manage water entering the site, protecting cap layers prior to vegetation.

The project team collaborated to create a combined earth support and geosynthetic installation system to construct 6,822 linear ft of lined anchor trench installed to a depth of 16 ft. The design allowed for two different rolled geosynthetic materials to be installed vertically in a trench to a depth of up to 16 ft more safely than the original design and at a rate that was more than seven times faster than the initial pace. The team targeted winter months for anchor trench installation when capping was no longer feasible. Working through a record snow year, crews made a significant schedule savings by installing 5,000 linear ft in freezing conditions.