The World Infrastructure

The 10 Largest Drinking-Water Treatment Plants in the World

Clean water requires investment in infrastructure

1. James W. Jardine Water Purification Plant, Chicago; capacity of 1.4 billion gallons per day. Designed and built by Chicago’s Bureau of Engineering, the plant began operating in 1964. It stands on a man-made, 61-acre peninsula that extends into Lake Michigan. The original 1,100-ft-long, 180-ft-wide plant extended from 36 ft below lake level to 25 ft above. Water is drawn into the plant from two crib structures two miles offshore and transported through tunnels located almost 200 ft beneath the lake and ranging in diameter from 10 to 20 ft. Inside the plant, rotating screens catch fish and debris. From there, giant pumps lift the water 25 ft, after which it is chemically treated with chlorine to kill microbes and activated carbon to remove objectionable tastes and odors. Next, fluoride is added for healthier teeth. Finally, aluminum sulfate, or alum, is mixed in about an hour into the process to increase the stickiness of microscopic solids, which then adhere to each other, creating floc. Large paddles—flocculators—assist with the mixing of alum and water. One of the very last chemicals added, polyphosphate, is used to coat the inside of Chicago's pipes, preventing the lead in old plumbing from leaching into the water supply. Then, the water is pumped into settling tanks, where the floc sinks to the bottom. This sedimentation phase eliminates roughly 90% of the particulate matter from the water. Finally, the water is filtered in one of 96 swimming-pool-sized tanks that are filled with a layer of coarse gravel under an upper layer of fine sand; together, these layers effectively filter much of the remaining floc and debris from the water. Construction lasted 13 years and cost $105 million. It supplies about 64% of the city’s residents.

Photo Courtesy Chicago Dept. of Water Management

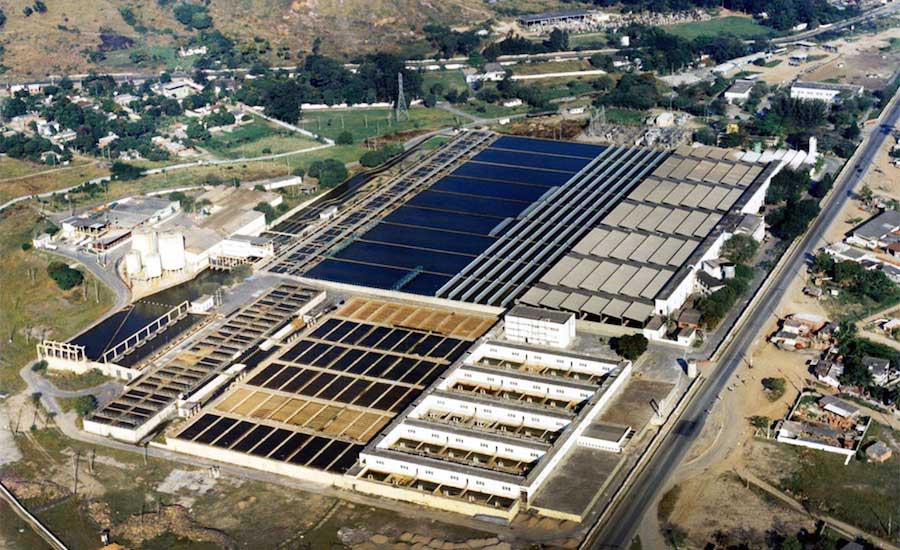

2. Guandu Water Treatment Plant, Rio de Janeiro; capacity of 981 million gallons per day. The plant was built in 1955. The raw-water supply for the plant originates in the nearby Paraiba do Sul River Basin, north of the city. Pumped 50 meters uphill, the water is used first to generate hydroelectric power as it flows downhill; next, it flows into the man-made Guandu River and then to the treatment plant. It is a conventional plant that employs chemical coagulation, flocculation, sedimentation, filtration and disinfection, as well as pH correction. The first phase of construction was done by Empresa Brasileira de Águas (EBA), and the second phase was constructed by Yamagata Engenharia. It has nine settling basins. Owned and operated by Companhia Estadual de Águas e Esgotos (CEDAE), the plant supplies 9 million people.

Photo Courtesy CEDAE

3. General San Martín Water Treatment Plant, Buenos Aires, Argentina; capacity of 894 million gallons per day. The plant was designed by the Technical Office of the National Commission for Sanitation Works. The reserve filters and new intake tower were built by the Roversi, del Bono&Cía firm; the settling basins by Fernández Poblet y Ortúzar; the impeller pump buildings and the water lifting stations by Broggi Hermanos and the office buildings by Carlos H. Martini. More challenging works like the subfluvial tunnel were built by the Societé des Grands Travaux de Marseille. The metallic coating of the tunnel, machinery, pipelines and other materials that were not yet being manufactured in Argentina were supplied by the Legación Argentina en Londrés through a private tender. The plant features 20 settling basins: 12 of them with static technology of horizontal flow, and 8 of them dynamic of upward-flow. The plant opened in 1913. Of the total population of the province and the city of Buenos Aires, 18 million, the San Martín plant supplies 32% of the population. The plant’s owner is Agua y Saneamientos Argentinos S.A (AySA)

Photo Courtesy AYSA

4. Prospect Water Filtration Plant, Sydney; capacity of 792 million gallons per day. Because it is a high-rate contact filtration plant, it does not contain any settling tanks. For this plant, hydraulic flash mixing was developed at a scale never before attempted. Due to the limited amount of head available, mixing via radial and axial agitators was discounted in preference for a hydraulic mixing arrangement. A jet of the chemical is pumped into the path of a jet of water to disperse the dosed chemical within the process water. Prior to the construction of Prospect, this technology had been implemented only on smaller-scale plants. Prospect supplies 85% of Greater Sydney’s drinking water. Greater Sydney now has a total population of just under 5 million, so Prospect is supplying drinking water to around 4 million people each day. On average, it supplies 337 million gallons per day. Prospect Water Group, a joint venture of Australian consultants CMPS&F and Sinclair Knight Mertz. is the plant's principal designer. It was built under a 25-year build, own, operate and transfer (BOOT) contract between Sydney Water Corp. and the Prospect Water Partnership, a consortium consisting of Lyonnaise des Eaux (now Suez), Ondeo and Unisuper. Degrémont, a subsidiary of Suez, is the plant operator. The project manager during construction was Civil & Civic, now trading as Bovis Lend Lease. The construction cost was $240 million. The plant opened in 1996.

Photo Courtesy of Sydney Water

5. Guarau Water Treatment Plant, Sao Paulo; capacity of 750 million gallons per day. Serete Engehnaria and James M. Montgomery Consulting Engineers (now known as MWH) designed the plant and the latter built it. The plant began operating in 1973. It receives raw water from the Cantareira system, a complex of six reservoirs in the hills north of the city. The plant uses alum to coagulate and flocculate particles, which are removed by settling and filtration. It has six settling basins. Chlorine is added to kill any bacteria. The plant’s original capacity was 250 million gallons per day, but it was later expanded several times to its present scale. When the region is not experiencing drought, the plant supplies nine million residents of the Sao Paulo metro area. Companhia de Saneamento Básico do Estado de São Paulo S.A (Sabesp), a state-owned water and wastewater utility, is the owner and operator.

Photo Courtesy CEDAE

6. Joseph Jensen Treatment Plant, Los Angeles; capacity of 750 million gallons per day. Designed by James M. Montgomery Consulting Engineers and constructed by Peter Kiewit Sons' Co. in 1972, the plant's original capacity was 450 mgd and featured 12 settling basins. The Hyman-JWP West joint venture's 1995 expansion increased its capacity to 750 mgd. The upgrade doubled the number of filters and tripled the sedimentation basins and filter washwater reclamation treatment capacity. The 125-acre plant uses the 444-mile-long California Aqueduct to treat water supplied from northern California. In 2005, an ozone disinfection system went on line; in 2008, the plant added a chlorine containment system and a fluoride system. Converting to ozone from chlorine disinfection was done to meet a state mandate; it also reduced tastes and odors in the tap water, perhaps caused by algae growth in the source water. Metropolitan Water District of Southern California is the owner and operator of the plant.

Photo Courtesy Los Angeles Metropolitan Water District

7. Bhandup Water Treatment Plant, Mumbai, India; capacity of 739 million gallons per day. The plant occupies 365 acres at the edge of Sanjay Gandhi National Park, a 40-sq-mile expanse of wooded hills that is home to deer, porcupine, leopards, antelope, monkeys, crocodiles and many species of snakes and birds. In July 2015, an 11-ft-long alligator wandered onto the plant grounds but was trussed up by guards within hours and returned to nearby Tulsi Lake. The park encompasses two lakes, Vihar Lake and Tulsi Lake, that serve as the plant's reservoirs. In 2016, a 15-kilometer-long, 5.5-meter-dia tunnel was completed in order to phase out aboveground pipelines bringing water to the plant from four reservoirs northeast of Mumbai. Crews are currently at work installing a 12.5-MW solar power plant at Bhandup that will supply a third of the power needed to operate the plant. Brihanmumbai Municipal Corp. owns and operates the plant, which is staffed by 450 workers.

Images Courtesy of Google Maps

8. Eugene Sawyer Water Purification Plant, Chicago; capacity of 720 million gallons per day. The Chicago Bureau of Engineering designed the plant, which was originally known as the South Water Filtration Plant. Opened in 1947, it was renamed in 2016. The original plant featured four settling basins and 80 filters and had a capacity of 280 million gallons per day. In 1964, a fifth settling basin and 40 more filters were added, swelling the capacity to 480 million gallons per day. Operational improvements over the past 20 years further increased its capacity to its present state. Built on a 45-acre site at the edge of Lake Michigan, the plant supplies about 36% of the city's residents, in addition to many of the southwestern suburbs. When it opened, a large part of the treatment plant was constructed with a green roof that covered more than 10 acres.

Photo Courtesy of Chicago Dept. of Water Management

9. La Mesa Water Treatment Plant Complex, Manila, Philippines; capacity of 700 million gallons per day. The La Mesa treatment complex consists of three plants. Designed by Camp, Dresser & McKee (now known as CDM Smith), La Mesa Treatment Plant 1 is a conventional plant with a capacity of 396 million gallons per day. Designed by Degrémont (now a part of Suez) and constructed in 1993, La Mesa Treatment Plant 2 is a pulsator-type plant with a capacity of 264 million gallons per day. La Mesa 2 is supplied by the Angat impounding reservoir and features pulsator-style clarifiers and sand filters. The latest expansion to the complex is the East La Mesa treatment plant, which has a capacity of 40 million gallons per day. Arup managed the engineering, procurement and construction. Maynilad Water Services owns the plants.

Image Courtesy of Google Maps

10. F.E. Weymouth Water Treatment Plant, Los Angeles; 520 million gallons per day capacity. The plant was originally designed by Hoover & Montgomery Consulting Engineers (a predecessor to MWH), and the primary contractor was the Griffith Co. The plant is located in the eastern suburb of La Verne, at the base of the San Gabriel Mountains. Completed in 1940, it is far more stylish than most treatment plants, with its Mission Revival-style architecture. It treats water from the Colorado River and the State Water Project, which imports supplies from Northern California. The original plant capacity was 100 million gallons per day. It was expanded in 1949 from two basins and 12 filters to four basins and 24 filters. In 1962, it was expanded to its current size with eight basins and 48 filters. The Walsh Group recently completed a $117-million retrofit to the plant to enable it to treat water with an oxygen-ozone system. Compared to chlorine, ozone destroys a wider range of micro-organisms, produces fewer byproducts and more effectively removes unpleasant tastes and odors. The plant is owned and operated by the Metropolitan Water District of Southern California. A 3-MW solar farm was added to the plant last summer, which will be used to offset about 45% of the electricity used to run the plant.

Photo Courtesy Los Angeles Metropolitan Water District

The drinking-water treatment market is facing financing challenges.

"Restoring aging water infrastructures is a challenge due to cost. Only about one-third of water systems earn enough revenue to cover replacement costs," says Blair Lavoie, president of MWH Constructors. "The U.S. has a big water infrastructure gap—the level of treatment should be improved," comments Marie-Ange Debon, group deputy chief executive officer in charge of the international division of Suez. "In the U.S., it's a fragmented market with many small plants, which makes it difficult to share utilities and equipment. There is still a lot of investment needed in the U.S. to improve water quality."

Suez acquired GE Water & Process Technologies for $3.7 billion in September 2017 and now has approximately $10 billion in annual water revenues. The firm is involved in constructing water facilities in 70 countries and operates water or wastewater plants in more than 40 countries.

Investment needs differ in accordance with levels of development.

Investment needs differ in accordance with levels of development. "In developed countries, we see growth in rehabilitation work and projects to improve the quality of installations," says Debon. "Emerging countries have greater need for new primary infrastructure. China and India have more than 5% growth, and Southeast Asia, Africa and Latin America are also growing. There is also a second level of development to improve the quality of rivers in many countries."

Financing approaches are also shifting. "Many countries that have been postponing investment in water programs due to other priorities or budget constraints have started looking at implementing ambitious plans by way of recurring to private financing," says Silvio Oliva, chief executive officer of Fisia Italimpianti, a subsidiary of Salini Impregilo Group. "Argentina and Peru are two countries [that are going in this direction]. In order to succeed with this approach, there needs to be a valid legislative scheme and adequate guarantees."

"We are seeing an increase in alternative or integrated delivery, program management and other approaches to bring water infrastructure projects to construction faster," says Jonathan Pressdee, vice president and drinking-water market-sector leader at AECOM. "We are not just talking a traditional P3. This can be debt financing to kick-start projects and performance contracting for shared risk."

New Treatment Technologies

New treatment technologies are being adopted or evaluated. "One new method is using membrane filtration differently, reducing the need for chemical cleaning and less frequent backwashing to simplify operation, reduce life-cycle costs and, consequently, much reduced risk of fiber breakage," says Pressdee. "We also see developments with ceramic filtration materials as alternatives to polymeric membranes and potentially as a replacement for conventional media filtration over time. The enhanced pathogen-removal capabilities of these filtration systems are a major benefit when protecting public health. Reengineering of ion exchange resins targeting dissolved organic material also holds promise, as we treat increasingly challenging surface waters as we diversify our water supplies."

Automation also is bringing greater efficiencies to treatment plants. "More and more digital technologies [are being implemented] that allow real-time and remote detection and remote management of equipment and plants," explains Debon. "These technologies allow fully remote operation of pumping stations."

The aging workforce in the water sector is creating interest in plant automation. "Water-plant operators are retiring, and the public sector is losing experienced personnel," says Pressdee. "[The water industry struggles] to attract younger people to operate facilities. This struggle has made facility automation an attractive alternative. The trend is driving automation concepts—smarter controls, algorithms, data-driven approaches to managing infrastructure and so on."

"Data is in buckets now," comments Bob Hulsey, global practice rechnology leader at Black & Veatch. "We can now get it to a place where people can get it quickly so people can use it in dealing with emergencies."

The Impact of Climate Change

Mother Nature is also having her say. "Another market driver we have seen this year is the impact of climate change on water availability and demand and the social perception of and responses to water-related risks, such as droughts, floods and pollution," says Lavoie. "The devastating droughts and hurricanes we have encountered this year have caused a lot of concern in areas [such as] water and disaster risk management, water supply and quality, drainage and flood management."

Pressdee points out, “Severe weather events—like the recent fires and flooding—impact our surface-water and water-treatment systems. These events can change the chemistry of the water in the systems that can result in water-quality issues like taste, odor, algae and so on."

One example of a project directly linked to climate conditions is an advanced water-recycling plant that Suez broke ground on last month in Perth, Australia. The Perth region has experienced more than a decade of dwindling rain, which has impacted groundwater supplies. "This re-use plant will allow the city to treat water and achieve a drinking-water quality level while putting water back into the aquifer," comments Debon. The plant will employ ultrafiltration, reverse osmosis and ultraviolet disinfection, while recharging up to 3.7 billion gallons per year. It should be operational in 2019.

"Having come out of the long drought—at least temporarily—California is a good example of looking to alternative sources for water supply," says Hulsey. "The Orange County Water District is expanding their groundwater replenishment system. One of our inland clients is expanding its brackish water supply and looking to recover more of the water for potable use," producing less brine to discharge to the brine line.

"Whether highly treated wastewater effluent or brackish inland sources or seawater desalination—all [these types of reuse] are expected to be a growing and significant part of our water portfolio for the foreseeable future," says Pressdee.

Another emerging threat is algal blooms, a seasonal phenomena during the past five years on Lake Erie. "Concern for toxins produced from harmful algal blooms has resulted in an organized approach that regulators are adopting to ensure control of these chemicals in potable water," says Hulsey. "For instance, the state of Ohio has a requirement that utilities that measure mycrocystin in their raw water above a trigger value have to come up with a plan to address how those toxins would be removed through their existing treatment processes and/or additional treatment processes to be included in the future."

One nation making big strides is India. "It has been a very active market for the past two years," says Debon. "The country is trying to optimize its networks in order to use less water: improving water pressure by replacing pipes and installing new meters." The effort is taking place in Bangalore, Mumbai, Kolkata, Delhi and Pune.