An economic development corporation based in Cleveland has selected a Danish mono-bucket foundation design that will resist extreme ice loads and require no pile-driving for an 18-MW Icebreaker offshore wind turbine demo project in Lake Erie.

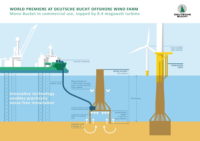

Developed by Denmark-based Universal Foundation, the foundation support is an all-in-one steel structure consisting of a monopile shaft attached to a 52-ft-dia bucket, according to Lake Erie Energy Development Corp. (LeedCo).

"Universal Foundation's mono bucket recently emerged as one of the most promising technology developments in the European offshore wind industry," says Lorry Wagner, LeedCo president.

LeedCo says installation uses "a unique suction system that requires no pile-driving or dredging, eliminating noise and soil disturbance." Final design completion is expected next year.

The team designed for worst-case winter conditions. "We designed an ice cone that will surround the foundation. If ice impinges on the foundation, it will move up the ice cone and fracture—that's how we will keep the forces off the foundation," Wagner says.

The mono bucket will achieve significant cost savings while meeting the technical performance requirements for Lake Erie's soil and winter weather conditions, Wagner adds, saying, "It is lighter than our original concept, requires significantly less time on the water during construction and can be fabricated locally."

Based on LeedCo's evaluation as well as other European market studies, the non-profit has concluded that, compared to the 2013 monopile concept, using the mono bucket can reduce fabrication costs by 10% to 15% and save 30% to 50% on installation costs.

To evaluate the mono-bucket design, LeedCo considered its technical performance, manufacturing costs, installation costs and comparative risks. Evaluators included veteran offshore-wind engineers from U.K.-based Offshore Design Engineering and wind-industry supply-chain experts from Cleveland-based GLWN, formerly Great Lakes Wind Network. Fred Olsen Windcarrier of Norway is a key partner in the installation of the first offshore wind project in Lake Erie.

LeedCo selected Cleveland-based American Tank & Fabricating Co. to represent U.S. fabricators during the final design process.

"This is yet another innovation we are bringing to the U.S. offshore-wind industry that will help meet the U.S. Dept. of Energy's cost of energy targets," Wagner says. "Not only does it move Icebreaker forward, it enables the Lake Erie region to become a central hub of the U.S. offshore-wind industry."

To date, the project has received $6.8 million in funding from DOE.

The U.S. Army Cold Regions Research Lab in Hanover, N.H., has completed studies of statistical distribution of annual maximum thermal ice growth. Steve Daly, a researcher at the lab, says that involved "studying weather conditions around the lake and developing a model to estimate ice thickness from thermal growth." His team is working on historical satellite tracking of ice ridges using satellite imagery and creating models to help with predictions to assist with the unique challenges of designing offshore wind turbines for a lake that freezes.

Dr. Esa Eranti, owner of Eranti Engineering, Finland, and Leedco research partner, evaluated the conditions in Lake Erie and used his experience along with the design codes to develop the appropriate solution, Wagner says. "He has been testing ice structures in Finland for over 35 years."

Eranti was responsible for the ice-cone design for the Pori I project in fresh waters in the Bay of Bothnia, Finland, which sees much greater ice loads every year than in Lake Erie.