What Can AI Do For You?

Artificial Intelligence Sees New Connections in Project Data

The Digital Grotesque II project is a 3D-printed architectural grotto based on the output of a computer tasked with generating a complex structure to fit a set of preset parameters.

PHOTO BY MICHAEL LYRENMANN, COURTESY OF DIGITAL GROTESQUE II

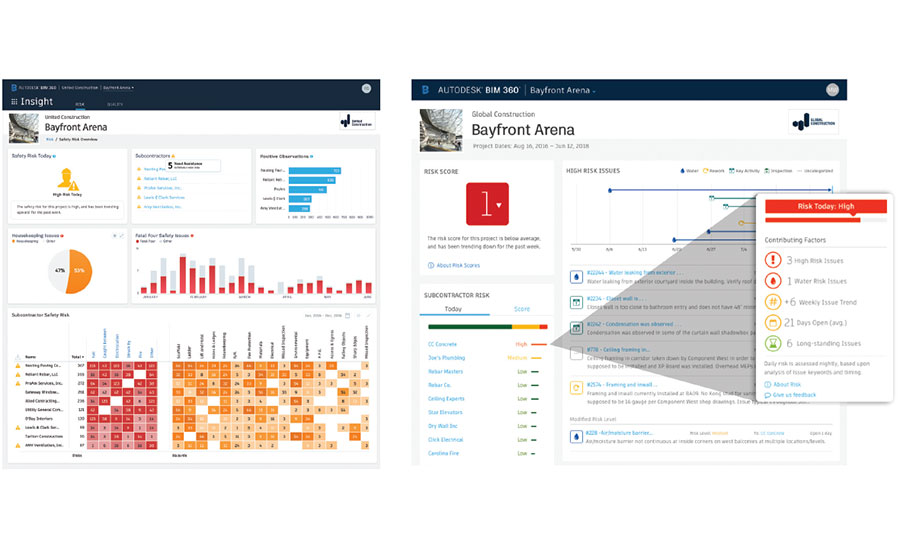

Project IQ for Autodesk BIM 360 applies advanced machine learning to construction data to anticipate delays and safety issues.

IMAGE COURTESY OF AUTODESK

The ALICE algorithm was used to settle a project team’s dispute over construction sequencing on a building project. Two competing methods were mixed together and another crew was added at the right time to speed the project along.

IMAGE COURTESY OF ALICE TECHNOLOGIES

Designing a building, developing a constructible model from a design or working out how to go about constructing a complicated model are all tasks that already contain some degree of automation. So when researchers and others in the architectural, engineering and construction world start talking about bringing artificial intelligence into the mix, many say it’s already here. But recent advances in generative design, safety analysis and 5D scheduling are only the first hints of what sophisticated algorithms and deep-learning AI can bring to construction.

Getting smart algorithms and other AI-derived technologies onto the project team may not be as far-fetched an idea as it once was. But rather than having a computer that takes over the existing job duties of an architect or engineer, those professions may soon have some form of AI-based assistant offering options and providing clarifications all along the way. But letting a computer process project data and spit out answers will probably not come in a single-button-press solution.

“People are losing their minds about it, but it’s just an algorithm.”

– René Morkos, Alice Technologies

“I think the discussion of AI in the AEC industry right now falls into three categories,” says Michael Bergin, Autodesk principal research scientist and head of the company’s industry research team for architecture, engineering and construction. “You can have a dashboard that provides feedback as you make necessary changes, a design tool that is itself generating and proposing suggestions, or a space you enter problems into and the computer sends back solutions.” None of these options is designed to do the entire job of a designer or engineer, says Bergin, but he notes the development of these AI-based tools is moving much faster than many in the industry realize. In the same way 3D rendering advanced by leaps and bounds in recent decades to change the way models are iterated upon, Bergin says computer algorithms that “solve” the problems in design and constructibility of buildings and structures are due relatively soon.

“All of these tools are still very new and not yet deployed at scale, but we look at them the same way we do any tool: How does it allow us to work more efficiently? How does it deliver value?” says Alan Robles, associate at Gensler. He and his team have been evaluating various technologies to improve an architect’s workflow, and he says AI may not only offer ways to free up architects’ time to explore more design possibilities, but even automatically include elements of the constructible model far earlier in the process. “We could come out of the game much more informed on areas where we used to need consultants,” he says. “Lighting, MEP, all the things we traditionally push down the line, can be addressed much sooner.”

But for Robles, the aim isn’t for AI to become the architect. Instead, he sees it as one more way to speed the iterative process, giving architects more time to consider their options. “It’s this ability for us to go from examining a site condition to considering multiple versions of how we could solve for the design challenge within that site. Then we’re deciding which one we want from a generative test fitting, then push that model to a virtual reality environment for further exploration,” he says. “All of that in minutes, rather than hours of working in the model like today.”

Robles says architects and other designers shouldn’t resent the advances of generative design and other AI-related fields in their practices. “AI has the potential to dramatically change an organization, and it’s really important to look at how we transition into those tools,” he says. “It’s important to look at them as tools. AI is not a designer—it helps us execute.”

Just Let the Computer Do It

The public perception of what computer-generated architecture would look like tends to evoke inhuman, even monstrous shapes. When a computer is given a set of parameters to solve within a space with few other constraints, unusual, alien shapes can result. The 2017 art exhibit known as Digital Grotesque II (seen above and on the cover of this issue) is the result of Swiss architect Michael Hansmeyer and his team using computer-generated designs and 3D-printing techniques to fulfill an unusual commission from the Centre Pompidou museum in Paris.

Digital Grotesque II . Printing Architecture - Full Version from Digital Grotesque on Vimeo.

“We wanted to explore what kind of forms could be conceivable using a purely algorithmic approach—forms that would have been undrawable, and also unmanufacturable, using traditional means,” Hansmeyer told ENR. “The computer thus became more than a tool for efficiency—rather, it became a partner in design and a tool to expand our imaginations.”

Instead of having a computer riff on existing architectural styles, Hansmeyer’s team developed an algorithm that would focus on two concepts—depth complexity, or how often light bounces off surfaces before it meets the eye, and “experiencability,” their term for how much the visitor has to move around the form or change perspective in order to see all of it.

When Autodesk’s internal studio the Living was designing a new research office in the MaRS innovation district in Toronto, it took the opportunity to allow for applying some generative design principles to “solve” the space for daylighting, employee work styles and interconnectivity, and even their desire for proximity to more scenic outside views. Autodesk began moving into the completed space in 2017. Images Courtesy of Autodesk

These parameters and the team’s algorithm were fed into the EULER supercomputer cluster at ETH Zurich, which then generated thousands of complex 3D designs that met these preset instructions. The team then blended the 10 results that most satisfied the two parameters and used a sand-based, additive manufacturing process to 3D print a 3.5-meter-tall, seven-ton rendition of the final design.

While the eerie forms from Hansmeyer’s exhibit are technically computer-designed, they fall more into the field of parametric design, where computers are given a few specific qualities to meet and grind away at, finding a result that satisfies the values. This technique has existed in design software for some time, and is one of the underlying technologies in many popular design suites.

But much of the recent work in AI that has garnered attention in the architectural and design world is in generative design and so-called “deep learning” algorithms. Here, a computer is tasked with a set of fairly complex problems to resolve, and the most successful of each solution set can then be fed back into the system to improve and refine future results.

“The term ‘generative design’ has been around for decades,” says Autodesk’s Bergin. “Where we’re putting a lot of effort right now is taking generative design to where not a great deal of rework will be required at the end.”

Autodesk has invested heavily in recent years in improving its generative design software so that industrial designers can put complex physical requirements into the algorithm, allowing computers to come up with designs for bicycle frames and aerospace components that maximize structural strength. Autodesk developed these in what it called Project Dreamcatcher, and some of the fruits of that work are now found in its commercially available program, Generative Design, an add-on for the Autodesk Fusion suite.

According to Bergin, this initial focus on industrial design was due to the freedom modern 3D printing offered in producing the shapes generative design algorithms spat out. “We realized we can build anything with additive metals, and we have an algorithm that can come up with wild designs,” he recalls. “So the Autodesk executive team put rocket boosters on that project, and here we are four years later.”

The company has not yet released a true generative design product for the architectural and engineering market, but Bergin and his team believe that may be the next natural step for the technology. “The exciting thing about the architecture and engineering field is that it’s an order of magnitude less complicated in the number of parts,” he says. “Compared to the level of complexity found in automotive or aerospace engineering, you have relatively primitive components—doors, walls, ceilings.”

While he does then concede there’s more to the industry than placing a few doors and windows, Bergin still thinks the industry will be warming up to AI as new products come to market. “I see greater opportunities in the near term for AI and machine learning to accelerate the AEC field. I see it coming in the next few years. The companies acting the most aggressively in this will see big changes.”

While the architect’s practice may continue to change as AI-derived systems advance, the rest of construction may also see benefits. Rather than teaching a computer algorithm to keep up with the creativity of designers, there are more tedious and repetitive tasks further along the project life cycle that are better suited to smarter automation, says Burcin Kaplanoglu, senior director of product and industry strategy for Oracle’s construction and engineering global business unit. “Rather than seeing more advances in generative design up front, I think in the next few years there will be more traction in the engineering side, in selecting the best design based on what’s needed,” he says.

Kaplanoglu says Oracle is currently looking to bring AI and machine learning to a broader array of its offerings for the AEC industry. But he says the hardest part—gathering the sheer volume of raw project data that is necessary to train and improve the computer algorithms to a usable state—is already happening. “The cloud is the space where this is all going to happen, making sense of all the data and getting what is useful,” he says. “The real challenge is that you can go so many different directions with all of this, and we need to find where is the best value for construction.”

Oracle already offers some machine-learning insights in its enterprise cloud services, but these are mostly focused on providing advice on better targeting customers for sales and managing client lists. But that is expected to change. “Right now we have Primavera P6 in scheduling; we’re dominate in the market,” says Kaplanoglu. “So for us, there’s a lot of opportunity for machine learning in terms of scheduling, best practices, and identifying risks on projects that are hard to see.”

While Oracle considers how best to bring AI to its existing software, Kaplanoglu is careful to point out that this isn’t about trying to replace any of the existing jobs in engineering and construction. “It won’t eliminate people; it’ll just change the skill mix of the workforce we need,” he says. “If I do a repetitive task all day, it’s pretty boring! If the machines do that repetitive work, it’ll make our industry much more attractive for the younger generation.”

Algorithms don’t get bored, and can quickly compare large quantities of project data to see connections a human analyst might otherwise miss.

Image Courtesy of Alice Technologies

Getting Cleaner Data To Feed Your AI

But what insights will AI-based systems be able to produce from analyzing project data, which is often disorganized and changes terminology and frameworks from company to company and project to project? “The best thing you can do right now to prepare for this is get your data in order,” says Oracle’s Kaplanoglu. “There will be some tools down the road to make that process easier, but good data hygiene in design and documentation is crucial. I know it’s not very sexy, but it’s the best thing you can do to get on board.”

Making sense of project data to glean fresh AI insights is also the focus of Patricia Keaney, director of Autodesk’s BIM 360 enterprise products, who has been leading the research team developing the AI-based advisor Project IQ as well. The system uses AI-based deep-learning techniques to analyze past and current projects for safety and efficiency and provide targeted warnings about delays and threats to workers’ safety.

“Our most proactive customers started using BIM 360 almost a decade ago, collecting data on sites,” explains Keaney. “So we have this checklist, literally 30 million times someone or something went wrong on a project that the customer felt the need to document.” This information is the seed for the deep-learning engine behind Project IQ, and several large customers have signed up for a pilot to have their vast stores of project data ingested by the system. “Prior to applying AI, we could run reports and do basic analysis: how many issues are open, per project—anybody can query a data set like that,” says Keaney. “But with AI or machine learning, we can take that data and transform it by applying techniques to find patterns and correlations at a volume and a rate that normal humans simply cannot possibly process.”

“With the pilot today, folks out on project teams can log in each day and get daily risk assessment of their projects,” says Keaney. The projects in the pilot are running on the BIM 360 environment, and all of the project files are being analyzed by the Project IQ algorithm to identify risk factors.

Improving safety and learning from mistakes in project management are clear targets for machine-learning insights, but why not let the AI take a crack at redoing your whole construction schedule? That ambitious leap is the focus of Alice Technologies’ system that analyzes project data to make specific suggestions on sequencing and scheduling approaches. “People kind of lose their minds about it, but it’s just an algorithm,” says René Morkos, CEO of Alice Technologies. “It’s all based on continuous improvements from more usage, like a speech recognition algorithm that eventually learns human speech.”

Alice Technologies’ AI assistant, ALICE, works on some of the same principles used in generative design. Give it a construction schedule and the problems to be addressed as a sort of “recipe,” and it will try to meet it based on past analysis of similar projects.

Mortenson Construction is one of the companies testing out Alice Technologies’ scheduling assistant in its work on a hospital project. But the project team was facing a problem as different stakeholders argued over sequencing. “It was core-out versus a wedding-cake sequence,” recalls Morkos. “The superintendent insisted core-out was faster, but we ran both through the algorithm and there was no difference.” But ALICE is good for more than winning arguments with other team members; it also found that adding additional crews on certain phases of the wedding-cake sequencing approach did save time, and was able to suggest a hybrid plan that mixed the two approaches, shaving weeks off the project’s overall schedule.

“What we want is for the schedulers to be tweaking this rule set, because it can only be improved,” says Morkos. “Does it learn from the rules we give it? Yeah, sure. It’s a very powerful tool, no question. But it still needs someone somewhere to tell it how to fly.”

Related Article: Machine Learning Offers Insights for Assembling Project Teams