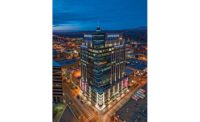

Hogan & Associates Selected as 2018 Intermountain Contractor of the Year

The new Farmington High School, recently completed by Hogan & Associates, is among the more than 300 school projects the contractor has performed during its history.

PHOTO COURTESY OF HOGAN & ASSOCIATES

Hogan & Associates relies on the ability of its people to self-perform many critical tasks— such as placing concrete—to move a job forward.

PHOTO COURTESY OF HOGAN & ASSOCIATES

The completion dates for Hogan & Associates’ projects are often more tangible than numbers on a contract or dates highlighted on a jobsite calendar.

“‘The kids are coming! The kids are going to be here, and we have to be done!’ That is what we always start telling our people when we’re close to finishing a project,” says Cris Hogan, president of the firm.

Hogan is the third generation of his family to lead the company, now the leading builder of K-12 facilities in Utah. The firm was founded in 1945 by his grandfather Eric Hogan and Darrell “Bud” Tingey. Operating as Hogan and Tingey Construction, the company built homes to meet the post-World War II demand but soon ventured into commercial building with its first school project. In 1995, Hogan and Tingey split into separate companies.

For the past three years, Hogan & Associates has earned the No. 6 spot on ENR Mountain States’ Top Contractors ranking. The firm, which has built major projects for 31 school districts in Utah, Idaho, Wyoming and Nevada, had $290 million in regional revenue in 2017.

In 1988, it became a pioneer in construction management with the first construction manager/general contractor contract in Utah for Northridge High School in the Davis School District. Since then, Hogan & Associates has delivered 398 CM/GC projects, the majority of them school buildings.

“Doing work for school districts and building schools became important from early on in the history of the company because in Utah, we have a lot of kids,” Hogan says. “The payment is also more secure than some other segments, and it has become one of our core markets. At some point, we and our clients decided to try out CM/GC because it is more collaborative and, working with the architect, you can have more feedback as far as the constructibility of the project.”

He adds that over the years, the delivery methods and relationships the firm has developed have become even more important as timelines to complete projects have shortened.

“It used to be there might be a bond election to build a new school and then if it passed, you’d see the projects come out for bid a year later,” he says. “Today, the districts might already have the architects on board before the election. Sometimes we’ve been along too as construction managers. It can give the public a better idea of what the project will be and how much it’s going to cost. If the bond passes, we might break ground the next week.”

Aaron Metcalfe has been the firm’s chief marketing officer for the past 12 years. He attributes some of the company’s success and its ability to meet compressed schedules to its increasing capacity to self-perform a significant amount of the work.

“Self-performing work has been critical to our success.”

– Aaron Metcalfe, Chief Marketing Officer, Hogan & Associates

“We have the ability and the manpower to push projects and keep them on budget,” Metcalfe says. “We can pour concrete, erect steel and self-perform other work because a lot of our people have been brought up through the trades and they know how to do a lot of different things. Self-performing work has been critical to our success.”

Building solid client relationships has been even more important, Hogan says. “We try to keep in touch with decision makers and attend board meetings. We want to stay involved with the districts and the architects.”

Architect Jeanne Jackson specializes in designing educational spaces, particularly K-12, at Salt Lake City-based VCBO Architecture. Jackson has worked with Hogan on the construction of nearly 20 school projects. Most recently, Hogan built the $75-million Farmington High School she designed in the city of Farmington, about 16 miles north of Salt Lake City.

“Hogan is really part of the team when we do these projects,” says Jackson. “They get involved early and help set the schedule. It has been great to have them involved in things, especially in helping work through the design and with site development.”

Jackson says the Hogan team was instrumental in site prep for the school. Built within a floodplain, the school site has loose soils and a high water table.

“They brought in almost 7 feet of fill material and surcharged the soil while we were working on programing and finishing drawings,” says Jackson. “That way, we were ready to go in the spring and start putting in footings. They were just very proactive.”

The 405,000-sq-ft school opens this year with innovative features such as modular, movable furniture in classrooms, dry-erase surfaces and private offices for teachers. Energy use will be decreased thanks to a ground-source heat-exchange system installed under the playing field adjacent to the school and through photovoltaic panels on the overhead canopies at a district-owned maintenance facility next to the school grounds.

Jackson says energy-saving systems were developed on previous VCBO-Hogan projects for the Davis district at the Odyssey and Endeavour elementary schools. She notes that Hogan takes extra care to build energy-efficient buildings and make them unique and appealing to students.

“Endeavour is named for the Space Shuttle and has a space-exploration theme,” she says. After the bid, the district said it wanted to hang some sculpted models of planets from the ceiling in the media center. Mike Hogan, the firm’s past president and the father of Cris Hogan, was the project manager.

“He sought out someone who could fabricate those for us and get that done for the client,” Jackson says. “We had these planets, and Mike said to me, ‘Don’t you want a Saturn-type planet with rings?’ and I felt like we’d already spent enough of the client’s money on this, and so I said I thought it was all right without it. I came back to the site one day and Mike had gone out and spent his own money to have a Saturn with rings built and put up there. They’re just always interested in finding ways to add special touches to a project.”

Jackson notes that the contractor also has been helpful with value engineering to contain costs.

Patrick Alcorn is facilities manager for the city of West Jordan, about 15 miles southwest of Salt Lake City, where Hogan is completing a $17-million, 130,000-sq-ft public-works facility. “[Hogan] did extensive value engineering on this project,” says Alcorn. “They suggested using an InsulTech block [an insulated structural block with a veneer finish] for the project and ended up saving quite a bit.”

He says the CM/GC project is running behind schedule because of bad weather earlier in the year. “Hogan is doing everything they can to get us in this building, and their onsite people have been great to work with,” Alcorn says.

Cris Hogan says the company plans to maintain its commitment to K-12 building and municipal projects but has been taking on more health care work lately.

“We’re not really looking to expand anymore geographically,” he says. “We’re really dedicated to the markets we have here in Utah and across the region. We want to stay focused on our product and the clients and our reputation of high-quality work for them.”