ENR MidAtlantic 2018 Best Projects

Best Cultural/Worship: Museum of the Bible

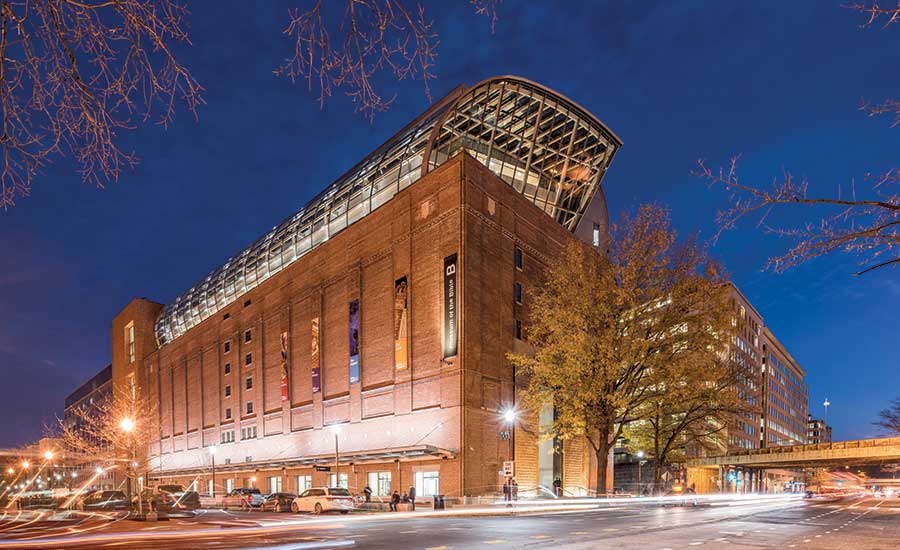

While museums can often require more than a decade of planning, design and construction, the $254-million, 430,000-sq-ft Museum of the Bible project took five years from concept to grand opening.

PHOTO BY ALEX FRADKIN, COURTESY OF CLARK CONSTRUCTION GROUP

While museums can often require more than a decade of planning, design and construction, the $254-million, 430,000-sq-ft Museum of the Bible project took five years from concept to grand opening.

PHOTO BY ALEX FRADKIN, COURTESY OF CLARK CONSTRUCTION GROUP

While museums can often require more than a decade of planning, design and construction, the $254-million, 430,000-sq-ft Museum of the Bible project took five years from concept to grand opening.

PHOTO BY ALEX FRADKIN, COURTESY OF CLARK CONSTRUCTION GROUP

Museum of the Bible

Washington, D.C.

Best Project

Owner: The Museum of the Bible

Lead Design Firm: SmithGroupJJR

General Contractor: Clark Construction Group

Structural Engineer: Tadjer-Cohen-Edelson Associates

Subcontractors: Southland (HVAC); Calvert (Masonry); Manganaro (Masonry and Drywall); Roschmann Steel & Glass (Galley Glazing); Icon (Non-Galley Glazing); Berlin (Structural Steel)

While museums can often require more than a decade of planning, design and construction, the $254-million, 430,000-sq-ft Museum of the Bible project took five years from concept to grand opening.

Portions of the museum occupy the Terminal Refrigerating and Warehouse Company Building, built in southwest Washington, D.C., in 1923. Over the course of the project, the team adapted 140,000 sq ft of warehouse space, performed 240,000 sq ft of infill construction and renovated an additional 50,000 sq ft of existing space.

To deliver the museum in an expedited 30-month construction phase, the project team says it maintained the original structure and removed every other floor, creating double-height floors.

The team also divided the museum into two separate projects. One group worked on demolition and new construction, while another handled the historic renovation. The team says that this plan enabled it to turn over exhibit spaces that were part of the historic renovation to the exhibit design team a year ahead of the grand opening.

The museum houses five floors of exhibit space, research laboratories, libraries, a lecture hall, a performing arts venue and a 500-seat ballroom.

Notable features include 37-foot-tall bronze entry gates with inscriptions from the Gutenberg Bible; a 140-ft-long LED arcade ceiling; a 117-ft-tall suspended monumental atrium stair with etched glass railings; and a 250-ft-long barreled curtain wall rooftop “galley” with views of the Washington skyline.

The new rooftop galley is a curvilinear glass-and-metal envelope, featuring visible structural ribs and a prow projecting over the entry facade. The roof is a system of curved AESS steel, clad with aluminum, segmented low-iron and fritted insulated glass units.

One Best Projects judge praised the building’s “extraordinary engineering and workmanship.” The judge also noted the “careful detailing done for a very complex asymmetric structure.”

Although a formal integrated project delivery agreement wasn’t used, judges also liked that the team adopted an IPD philosophy to help expedite the schedule. “That’s a trend of the future,” another judge said.

Architect SmithGroupJJR employed design-assist with HVAC contractor Southland to enable rapid feedback and expedited decisions. It also allowed work to overlap for several months.

To facilitate decisions, about 20 different mock-ups were created for spaces such as the atrium stairs, the decorative glass guardrail and various portions of the performance hall.

The project is located in a dense urban area with a CSX rail line to the south, a government office building to the east and an underground Washington Metropolitan Area Transit Authority (WMATA)rail line to the north.

The project team consulted with many agencies to review and get approval for the museum, including the Commission of Fine Arts, Historic Preservation Review Board, D.C. Preservation League, Advisory Neighborhood Commission, D.C. Dept. of Transportation and Dept. of Consumer and Regulatory Affairs, the D.C. Public Space Committee, electric utility Pepco, WMATA and CSX.

Related Article: ENR MidAtlantic's 2018 Best Projects: Region’s Top Work Sets High Bar