ENR Midwest’s 2020 Best Projects

Best Project Interior/Tenant Improvement: Starbucks Reserve Roastery

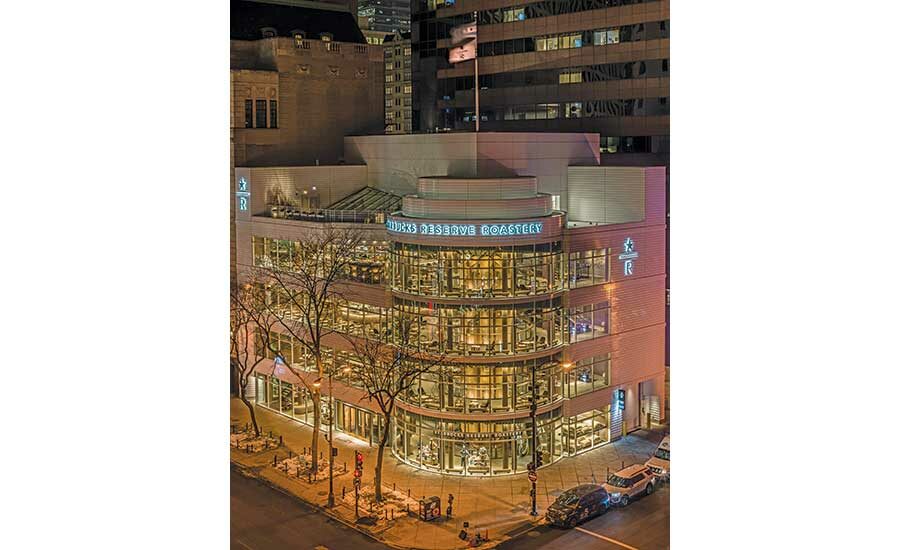

Starbucks Reserve Roastery Chicago

PHOTO BY MATT GLAC

Starbucks Reserve Roastery Chicago

Starbucks Reserve Roastery Chicago

Chicago

Best Project

Owner/Lead Design Firm: Starbucks Corp.

General Contractor: Pepper Construction Co.

Structural Engineer: CS Associates

MEP Engineer: Ove Arup Chicago USA

Architect of Record: Perkins and Will

The world’s largest Starbucks Reserve Roastery is on Chicago’s Michigan Avenue, and each year more than 200,000 lbs of coffee are roasted and served at the 43,000-sq-ft location.

When contractor Pepper Construction began work in September 2018, it had one year to turn a Crate and Barrel store into a customer experience that includes the region’s first curved escalator, a complex wood ceiling inspired by rays of the sun and a bronze colored 56-ft-tall steel and aluminum coffee cask.

Pepper also had to create a system to transport freshly roasted coffee beans throughout the five-floor roastery using bronze pipes that were connected to multiple coffee bars. All of the mechanical, heating and cooling systems that support the process were hidden in the walls and the ceilings thanks to a complex MEP design by engineer Arup.

Escalator fabrication took 18 months, another month to ship to Chicago and then six more months to assemble on site.

"Mitsubishi is the company that makes that escalator," says Brian Peter, Pepper's project executive. "We actually had a guy go visit their shop in Japan and see what was happening and learn about their fabrication process so that we could make sure we had all the tolerances that they required with the structure ready."

The existing structure’s walls and floor had to be modified to accept and support the showpiece. The installation tolerance was 1/64 of an inch. Pepper’s team worked with Mitsubishi to plot several hundred points on the ground to guide the curved escalator into place.

Each piece of the wooden ceiling had to be placed by hand in a specific order. Installation required six months of early coordination and the use of a laser positioning system during installation.

The project team knew that missing the grand opening or compromising the design couldn’t happen as Starbucks expected to have the store open for the holidays.

When a late change required the reconfiguration of the third floor and the redesign of the building’s mechanical system—one that normally would have resulted in a three-month schedule delay—Pepper Construction worked as a team with Perkins and Will, Starbucks and Arup to adjust its construction schedule.

"Starbucks initially wanted a packaging line on the third floor but, once they knew what demand there was for the Reserve Roasteries in New York and Milan, they realized they would need that space for customers," Peter explains. "We had already completed all of the structural modifications for the pack line and brought it into the building, we had reinforced the structure to hold it. Then we had to bring it into the building and then take it back out though the holes we brought it in."

The contractor instituted 20-hour workdays, seven days a week, from July through September to catch up. As a result, the project was completed in time for Starbucks’ grand opening in September 2019.