ENR New York’s 2020 Best Projects

Exoskeleton Keeps 53 West 53 Sturdy Atop Manhattan Museum: New York's Project of the Year

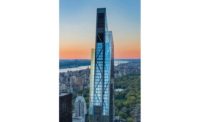

53 West 53’s concrete diagrid skeleton looms above the Museum of Modern Art.

PHOTO BY GILES ASHFORD

53 West 53 has a slenderness ratio of 1:12 because it sits on a tiny lot that used to house MoMA’s folk art museum.

PHOTO COURTESY LENDLEASE (US) CONSTRUCTION LMB INC.

Many of the building’s condominiums have views of Manhattan’s iconic green space.

PHOTO BY GILES ASHFORD

The diagrid columns that form 53 West 53’s exoskeleton double as an architectural feature in every room.

PHOTO: BY STEVEN KENT JOHNSON

Nothing was prefabricated except the apexes, Lendlease’s Mark Lubrano says.

PHOTO COURTESY LENDLEASE (US) CONSTRUCTION LMB INC.

The floor slabs’ became smaller as they went go up the building, making each slab’s shape unique and resulting in longer cycles to erect each story.

PHOTO COURTESY LENDLEASE (US) CONSTRUCTION LMB INC.

General contractor Lendlease used three self-climbing tower cranes, swapped out as construction climbed skyward, and two hoists.

PHOTO COURTESY LENDLEASE (US) CONSTRUCTION LMB INC.

53 West 53

New York, N.Y.

Residential/Hospitality Best Project

Key Players

Owners: Hines and Pontiac Land

Lead Design Firm: Ateliers Jean Nouvel

General Contractor: Lendlease Construction LMB Inc.

Civil Engineer: Langan

Structural and MEP Engineer: WSP USA

Architect of Record: Adamson Associates Architects

Interiors Architect of Record: SLCE Architects

Residential Interiors Design: Office of Thierry W. Despont Ltd.

The barely audible twangs of springs stretching and compressing can be heard when visiting the 75th floor of the 87-story 53 West 53 tower—aural evidence of its tuned mass damper at work, keeping steady the super-slender building that looms above Manhattan’s Museum of Modern Art. The condominium building, encompassing 730,000 sq ft on a footprint of just 17,713 sq ft, isn’t just susceptible to wind that can make residents feel like they’re on a swaying boat. Due to its design, it also lacks the normal number of interior columns typical in most similar buildings and needs the damper to keep from moving.

Making sure the building would remain stable despite its unusual design required exemplary teamwork. Structural engineers at WSP worked for more than a year to design an exoskeleton made up of irregularly shaped diagrids cast in concrete and connected via steel boxes called nodes—the building’s most visual exterior feature and its support system.

General contractor Lendlease used three self-climbing tower cranes, swapped out as construction work climbed skyward, and two hoists during construction. Geotechnical engineers at Langan conducted seismic planning and had to solve unexpected bedrock issues. Then there were the condos’ interiors, with high-end finishes that were customized for each of the 162 units, requiring lengthy modeling before installation.

“The entire team worked like a philharmonic orchestra,” says Silvian Marcus, WSP principal in charge. “Like violins, they played in unison.”

The innovations and extreme coordination among key participants and stakeholders are some of the reasons why 53 West 53 is ENR New York’s Project of the Year for 2020.

Making It Work

Developers Hines and Pontiac Land wanted to construct a “truly unique” building that exemplified cutting edge technology, materials and design philosophies,” says Hines managing director David Penick.

The slenderness of the tower, formerly known as 53W53, is enhanced with sloping facades on two opposing sides, which means the floors get progressively smaller as they rise. The building is topped with five pyramid-like apexes. Because architect Ateliers Jean Nouvel’s vision called for few interior columns, the team had to design another way to carry gravity and lateral loads, particularly those associated with wind and seismic demands. Enter the diagrid exoskeleton.

WSP’s engineers say they originally conceived an all-steel exoskeleton, which the client considered too expensive. So they had to figure out how to make the diagonals out of concrete, which “never at that time” had been done at such a scale, Marcus recalls. Starting around 2012, in daily morning meetings, he and Gustavo Oliveira, WSP vice president of properties and buildings structure, would discuss how to make it work.

A main issue was “when the diagonals converge, how to connect the rebar within the concrete,” Oliveira recalls. The engineering team used BIM models to test various scenarios of concrete and rebar aligned in many different directions, and physically tested the nodes. By 2014, a year before the project’s foundation broke ground, the team developed a “sort of steel box” dubbed “the glove” to be placed at 60 or so convergence locations, Marcus says, adding that the metal contractors “took our design and they improved that node … into something lighter and more efficient. The contractors get an A-plus.”

Oliveira says Legend Machine & Grinding fabricated the steel plate node assemblies, while SAS Stressteel produced large diameter bars; both were subcontracted by superstructure contractor Sorbara Construction.

“This is the first time that a diagrid structure of this magnitude and complexity has been done in concrete,” Penick says. “A significant amount of coordination had to be done when you consider a number of different technologies were used by a superstructure concrete subcontractor and the panelized curtain wall fabricator.”

Superstructure work did not begin until January 2016, more than one year after foundation work started.

What Lies Beneath

“The significant challenge at this site was getting to the depth of good quality bedrock, which varied by about 70 ft from east to west,” with zones of decomposed, weathered and poorer quality rock caused by a former stream, Langan geotechnical engineer Ronald Boyer says.

High capacity drilled caissons were needed at the site’s western end to transfer building loads to “competent bedrock” and below a tunnel structure under 53rd Street, he adds.

The lot for 53 West 53 once housed a folk art building. MoMA built three stories of new galleries on that spot, with this museum extension now directly underneath the condominium tower.

“The bottom first few floors of our building are MoMA gallery space, so we basically built a core shell for them,” explains Mark Lubrano, Lendlease vice president and project executive. 53 West 53’s two subcellar levels are directly below the galleries, and “our building rises above,” he says. The two buildings are not connected, however, with separate mechanical, electrical and plumbing systems, and an interstitial crawl space between the museum and the condo units.

It’s What’s Inside That Counts

The building is cast-in-place concrete, with custom built formwork and concrete poured into place, says Lubrano. “Nothing prefab except the apexes,” he adds.

“We had very elaborate custom systems for these diagrid columns,” Lubrano says. ”Each slab had formwork that was reused,” but was custom built. Also, because floor shapes changed as they rose and narrowed, it took the team about three to five days to erect each one, compared with two days for a building with equal size floor shapes throughout, Lubrano says.

The tower’s MEP systems are “pretty standard,” says Jonathan Policke, WSP vice president, mechanical designer and project manager. The team located cooling towers in the apexes, while mechanical systems equipment and duct routings are on floors 35-37. This roughly halfway point is ideal, says Gary Pomerantz, WSP executive vice president of building systems, because one loop for plumbing serves floors above and a second loop serves those below. This “keeps the pressures to something reasonable,” a challenge for very tall buildings, he says.

No matter what floor a condo occupies, all have a certain unique architectural element: the zig-zagging diagrid columns, each a different shape and angle within the apartment’s living rooms and bedrooms, looking like built-in modern art sculptures.

Other interior features were much more challenging to install. Finishes were almost entirely custom, so the team had to mock up and test each, sometimes repeatedly. It took more than a year to figure out how to install, without damage, materials and elements such as stone and onyx translucent with LED lights, highly polished walnut millwork on doors and trim, mirrors that a user can move up and down according to her height, solid nailed down oak flooring, motorized kitchen cabinet doors and glass front cabinetry from Italy.

Physical, Mental And Cultural Well-Being

Installing the facade of 53 West 53 also was a painstaking process, including use of a custom curtain wall by contractor Enclos. Its installation had to be coordinated with a heating system at the top of the building to prevent ice from accumulating on the dramatically angled apexes. A sudden cold spell last winter led to ice forming and falling “prior to the system being up and running,” Lubrano says.

The team quickly responded to prevent the ice from causing damage or injury. Crews also tailored most project sequencing around neighbors’ concerns of noise, light dispersion, traffic and other issues.

Jobsite attention to workforce safety and well-being was particularly strong, with workers able to access “Café 33” on the 33rd floor for food, phone charging, entertainment and rest.

But as a high-end luxury condo, 53 West 53 is most focused on amenities for its owners, including gyms, sports rooms, a pool bookended by “living walls” of plant life and more, not to mention the building’s biggest draw—MoMA itself.

“The close proximity to a world renowned art institution … allows us to offer a residential experience that” most condo developments don’t provide, Penick says, pointing to the “special benefactor” MoMA membership given to all residents.

Back to New York Region's Best Projects Display Innovation, Quality

.jpg?height=200&t=1637088509&width=200)