Robotic arms for tunnel boring machines, concrete rebar made of old wind turbine blades and machine learning to reduce concrete waste are among innovations emerging from the $16.7-billion civil construction program for the U.K.’s London - Birmingham high speed railroad, which began construction late last year.

These ideas are products of structured programs established by project owner HS2 Ltd. to stimulate innovation, mainly by small and medium enterprises.

One innovation involves cutting up old, composite wind turbine blades for use as concrete rebar, rather than burning resins off the blades to recycle them. If successful, the rebar would initially be used on non-structural elements.

“The wind industry has got thousands of blades being decommissioned,” says Graeme Jeremy, head of construction infrastructure at the National Composite Centre.

The center and the joint venture of Skanska Construction U.K. Ltd., Costain Ltd. and Strabag A.G. building high speed tunnels from the London terminal, came up with the idea last year and won HS2L support.

NCC is now preparing for some seven months of studies and development leading to trial manufacturing and testing. “A lot of fundamental questions” need to be answered, says Jeremy.

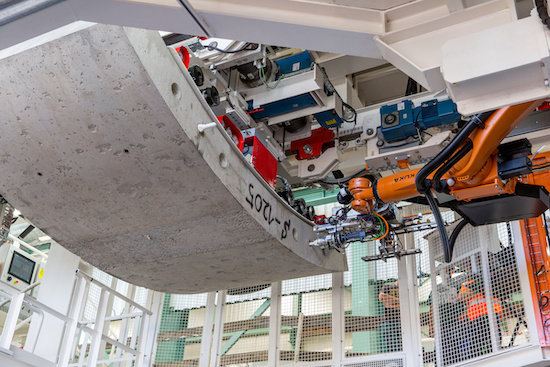

An innovation with more immediate application is due to be used this summer on two TBMs on the 16 km Chiltern twin tunnels.

The contract’s Align joint venture of Bouygues Travaux Publics, VolkerFitzpatrick and Sir Robert McAlpine developed a TBM-mounted robotic arm for repetitive and potentially dangerous work that would normally be done manually.

Tasks include removing wooden spacers between the tunnel’s 112,000 concrete lining segments and inserting connection dowels between them.

Having invested “a lot of work” in developing the device, “we would be happy to share with tunneling teams working on other projects across the world,” says Align's underground construction director Didier Jacques.

These innovations are among a 100 or so in HS2L’s portfolio drawn from the project’s supply chain, says Robert Cairns, HS2L’s innovation manager. About 70% involve SME’s, he adds.

SME’s from outside the railroad project are the prime targets for HS2L’s parallel Innovation Accelerator program. HS2L teamed up with the government’s Catapult innovation support program and Bruntwood SciTech, a private sector provider of technology space and resources.

About 100 applicants competed for the first five places on the program last summer, and another four similar cohorts will be recruited by the middle of next year, says Cairns.

The accelerator provides funding and four months support with resources and access to main contractors and other key industry players.

Among the first innovations to be chosen is one that aims to improve concrete delivery to work sites and eliminate waste, which amounts to 5% of the total production, according to its developer Cloud Cycle Ltd.

The system monitors in real time the slump and temperature of the concrete and location of ready mix trucks. “We can make sure the concrete is delivered right the first time and every time,” says the founding CEO Phillip White.

If applied across HS2, the ready mix concrete monitoring system could save 420,000 tonnes of concrete and 50,000 tonnes of carbon dioxide in its production, estimates White.

HS2L contributed nearly 30% of a $1.2 million grant to help Cloud Cycle commercialize its technology, with the government’s Innovate U.K. making up the balance. As well as funding, Cloud Cycle gains access to HS2’s contractors and suppliers to help develop its technology as part of the program.

Having built its business serving the ready mix delivery industry, Cloud Cycle’s horizon has now widened to include the whole supply chain, says White. Since gaining HS2L support, the company has grown from four staffers to 15, says White.

SMEs, such as Cloud Cycle, are “the lifeblood of innovation,” says Cairns. He won’t say how much HS2L will spend nurturing them but hints at “the low millions” annually on programs to make construction “smarter, greener and faster.”