Global Best Projects

Best Project, Airport/Port: Tema Port and Container Terminal Expansion Project

The new Tema port can handle vessels carrying 22,000 containers.

Photo courtesy of China Harbour Engineering Co.

Tema Port and Container Terminal Expansion

Tema, Ghana

BEST PROJECT

OWNER: Meridian Port Services Ltd.

LEAD DESIGN FIRM: Civil and Structural Engineer: CCCC-FHDI Engineering Co. Ltd.

LEAD CONTRACTOR: China Harbour Engineering Co. Ltd.

HARBOR ENGINEER: CCCC Fourth Harbor Engineering Co. Ltd.

PROJECT MANAGEMENT: AECOM

CONSULTANT: Artelia Group

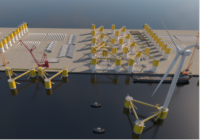

This project expands the capacity of a crucial West Africa freight hub in Ghana with four massive container vessel berths, 3,558 meters of breakwater and 1,400 m of wharf. This 127-hectare development will provide substantial economic benefits and growth for Ghana while providing 15 interns and 40 young local engineers with opportunities to advance skills and expand employment potential.

Team members from Ghana, South Africa, the U.S., U.K., Hong Kong, China, France, Ivory Coast and South Africa helped build the new port that can accommodate vessels with a capacity of 22,000 containers. Advanced testing methods and equipment helped optimize construction and minimize environmental impacts. The team tackled tough natural conditions such as hard earth material and strong waves, while protecting local sea turtles, marine mammals and fish.

Working within high surf and hard gneiss, the team used a multi-point berthing energy absorption design. “Normally in the fender design, it was assumed that berthing energy from one vessel will be absorbed only by one fender,” says Xie Shoupeng, a representative of China Harbour Engineering Co. “But actually, for a continuous berth, especially when the berthing angle of vessels is small, the vessel will be in contact with multiple fenders at the same time. By using multi-point berthing energy absorption design, the required fender performance can be significantly reduced.”

Use of Echoscope sonar technology with Trimble GPS real-time positioning and monitoring technology enabled placement of accropode blocks without human divers. “Echoscope provides installation image information, and Trimble GPS provides installation coordinate information to ensure the quality of block installation,” he says. “The measurement error can be controlled within centimeters. The installation coordinates can be compared with the design coordinates to ensure that the unit was installed according to the design coordinates. Real-time and visualized dynamic management of the whole process of the installation of the face protection block improved the quality of project construction.”

Drainage design and construction, performed by Eiffage Genie Civil, had to be integrated into China Harbour’s quay wall design to pass beneath the rear rail beam and between pile supports, notes Lucy McLane, AECOM communications coordinator for strategy & growth, Middle East & Africa. China Harbour designed special caisson units that accommodated precast concrete box culvert sections. The quay wall also was originally designed as a conventional gravity blockwork wall but was designed with 2,700-tonne caissons to save time. The caissons are approximately 19.4 m wide, 15.2 m deep and 19.3 m high. Seventy-four caissons were placed to form the wall rather than several thousand blocks, according to China Harbour and AECOM.

The project was completed below its $475-million budget and the fourth berth was completed several weeks ahead of schedule. “Ensuring that the full design package was completed in the first phase of the project allowed the construction teams to seamlessly continue activities without delay,” says AECOM’s McLane.

Hydraulic leveling (top left) and ground compaction (top right) helped assure accuracy in placing 2,700-tonne caissons for the quay wall; a breeding program and mItigation measures helped assure preservation of a sea turtle population.

Photo courtesy of China Harbour Engineering Co.

*Click the photos for more detail

Turtles and Training

The team took numerous measures to protect the local sea turtle population, such as raising a pipeline about 50 cm, minimizing underwater blasting and creating a breeding center on site.

McLane notes that a total of about 45,000 turtles were protected and hatched. “A long-term offset plan was put in place to improve and protect adjacent nesting beaches, leading to increased overall turtle hatchings,” she adds. “Programs included community and social education, awareness and interventions and nest protection from predators.”

The team also diverted existing stormwater discharge from the city of Tema from flowing onto the beach and into the ocean through a macro element/hydrocarbon separator structure, according to McLane. The team also monitored fish, marine mammals, ocean turbidity, sediment and water quality, as well as noise pollution and shoreline impacts.

Of more than 4,000 project staff, 90% were Ghanaians, notes McLane. “Having been exposed to international construction standards and health, safety and environment systems, the staff returning to the Ghanaian labor market have gained skills and training that will contribute to the growth of the economy,” she says.

The port itself is also key to Ghana’s economy, positioning the country as a key shipping and transshipment hub in West Africa. The layout allows for future expansion, and the semi-automated port, with a 100-year design life, has ISO 14001 compliance.