Amazon HQ2 Puts Concrete on an Embodied Carbon Diet

HQ2, in the National Landing Business Improvement District, is near the nation’s capital.

Photo by Sisson Studios courtesy of Clark Construction

Before the ground-breaking for Amazon’s 2.1-million-sq-ft Metropolitan Park office development across the Potomac River from the nation’s capital, Clark Construction Group’s John Swagart and Jeff King walked door to door, introducing themselves to shopkeepers near the MetPark site. The good-will ambassadors were pounding the pavement to inform MetPark’s neighbors of the plan to dig a 50-ft-deep hole—710 ft x 310 ft—and create two 22-story buildings.

The intros were a small part of Amazon’s community relations campaign. The Seattle-based e-commerce, cloud-computing and retail giant began implementing its good neighbor policies even before 2018, when it selected two Crystal City, Va., sites in Arlington County for Amazon HQ2—its $2.5-billion second headquarters that includes MetPark, and the planned 2.8-million-sq-ft PenPlace. HQ2 is by far the largest development in the National Landing Business Improvement District—a public-private BID that focuses on Crystal City and nearby Pentagon City and Potomac Yard.

Clark’s most novel neighborly gesture during the nearly two years of MetPark work has been to hand dog walkers some 600 treats, called Clark Barks. And the general contractor even set up an information booth at the farmers market and gave out dog-themed bandanas.

In addition to shops, the MetPark site is surrounded by nine buildings with more than 4,000 apartments and hotel rooms. To keep neighbors informed, Clark has held town hall meetings—virtually because of COVID-19. It also has created videos, emailed progress reports and posted alerts on its website about upcoming disruptions.

The event center contains mass timber (above). A batch plant near the MetPark site helps lower the concrete’s carbon footprint (below).

Photo (above) courtesy of Clark Construction; (below) courtesy Miller & Long

The communication is “very valuable” for residents, who generally find the project “fascinating, once they understand it,” says King, a vice president, who declines to provide the amount of Clark’s guaranteed-maximum-price contract. “John and I handle community engagement on every job, but even more so on this project,” he adds.

The MetPark team also is doing “even more” regarding large-scale green buildings, thanks to a ground-breaking focus on sustainability that could become a model for others. For example, mixes for the project’s 200,000 cu yd of concrete, including for the 890,000-sq-ft basement parking garage, have less embodied carbon (EC) than is the norm.

“A concrete structure is typically 35% to 40% of a building’s total carbon footprint,” says Brian Earle, a principal in the Washington, D.C., office of MetPark’s ZGF Architects. “We had to have an impact on that to be sustainable,” he adds.

Tracking at Least a 15% Reduction in EC

With the two buildings cast to levels 17 and 18, ZGF is tracking at least a 15% reduction in EC in the concrete over the baseline for the region. Earle calls the reduction “an industry-moving endeavor to pull off,” especially considering the job’s scale.

“We learned a significant reduction in EC is possible with current technology” and without adding cost, but an owner’s commitment is important, adds Michael Cropper, a senior associate with Thornton Tomasetti (TT), MetPark’s structural engineer.

The job’s carbon diet intensified in September 2019, when Amazon launched the Climate Pledge with co-founder Global Optimism. Each of the current 217 signatories has committed to operations that balance the greenhouse gases (GHGs) put into the atmosphere with those taken out—also known as net-zero operational carbon. And they have promised to do it by 2040, a decade ahead of the Paris Agreement signatories.

Toward this, by 2025, Amazon aims to indirectly power its operations by investing in renewable energy. For HQ2 and other facilities in Virginia, Amazon has contracted 82 MW of a 120-MW solar farm in Pittsylvania County, Va., that will be completed this spring.

“We’d been evaluating opportunities to reduce the carbon footprint of [MetPark] since the very beginning” of the project’s design in December 2018, says ZGF’s Earle. “After the announcement of the Climate Pledge, it became an area of increased focus.”

For the design team, the pledge was exciting yet unsettling. “We were in the middle of construction documents and entitlements and had to reevaluate” the buildings and make changes, which meant more reviews, says Earle.

The January 2020 construction start was only 15 months away, yet it typically takes 18 months to get approvals in Arlington County. In the end, the team secured approvals in eight months. “We had a good partnership with the county,” says Earle. “Amazon and the officials want the same things for the neighborhood.”

Clark Construction treated the below-grade work as one project, though the development has two 22-story buildings.

Photo by Sisson Studios courtesy Clark Construction

Electric Cook Stoves

To meet the pledge, ZGF introduced low-friction chillers and heat pumps for domestic hot water. It reduced the percentage of vision glass and added louvers to direct daylight into the spaces. And it specified electric cook stoves. “This combined with the solar power reduced the buildings’ operational carbon to net-zero,” says Earle.

MetPark is designed to achieve LEED Platinum certification. It will have green roofs, graywater exchange and stormwater heat exchangers.

A gesture to a more sustainable material than concrete is a 700-person-capacity ground-level event center that sports a cross-laminated timber ceiling supported by ten, 80-ft-long glue-laminated beams. The space will be shared with the community.

To support the target of 10% less EC in the concrete, TT issued a performance-based specification. “Performance specs give subs and producers the opportunity to get creative by taking away the barriers” of prescriptive specs, which are very specific, says Mark Tamaro, TT’s principal-in-charge. “We didn’t want to hamstring them on mix characteristics, including pumpability, workability and cure time.”

With a prescriptive approach, “there is more risk” for the structural engineer, adds Tamaro. “You might open yourself up to mixes that don’t perform as intended.”

To explore lower EC, ZGF used its Concrete LCA Tool—a simple Excel calculator, offered free of charge to anyone, for rapid life-cycle assessments of concrete mix designs and comparisons to regional practices.

Mass Excavation

Mat Slab

Structure

Structure Top Out

Clark Construction mapped out a detailed work sequence, in part to help communicate the job to the subcontractors.

Graphics courtesy of Clark Construction

*Click on the photos to enlarge

“EC tracking and reduction in our region is extremely new,” says Tamaro. As a result, bid forms went out with a primer introducing Environmental Product Declarations (EPDs), global warming potential (GWP) and related subjects. And bidders could use ZGF’s tool.

The EC target created another evaluation data point, but that did not slow bidding. “We had planned for it,” says Clark’s King, “because we needed partners to achieve our goals.”

The bid process was “unique for us and sparked good conversation at bid time,” King adds. The formula used to offer and evaluate bids could be replicated for other jobs, he says.

The EC reduction is generally a result of using less portland cement, mixing in recycled slag as a binding agent and adding an admixture called CarbonCure, which accounts for 3% to 5% of the 15% EC reduction in MetPark’s concrete, says ZGF.

CarbonCure’s set-up adds liquid carbon dioxide under pressure. Once injected into the mix, the CO immediately undergoes a mineralization process and becomes permanently embedded in the concrete, allowing for lower cement ratios, says CarbonCure Technologies, one of the first companies to win a grant from Amazon’s $2-billion Climate Pledge Fund, launched in June 2020 to nurture new technologies that reduce GHG emissions.

Two Concrete Contractors

At a total of 200,000 cu yd, MetPark has about five times more concrete than a typical Washington, D.C., office building job. That prompted Clark to divide the concrete works between two contractors—Miller & Long Co. Inc. for the 1.2-million-sq-ft building at the south end of the site and Clark Concrete for the 925,000-sq-ft north building.

Using the ZGF tool, Miller & Long estimated some of the mixes, which vary in strength, would have at least a 28% better impact on global warming potential than the baseline. “We’ve actually refined our mixes further and our actual results will be better than this value,” predicts James J. Martinoski, a Miller & Long vice president.

For the job, Miller & Long set up its own batch plant two blocks from its jobsite, on part of PenPlace’s 11-acre lot. The local plant cut travel distance for the concrete mixers and the associated EC.

“Our average EC cuts were greater than 10% to 15% in all our mix designs, compared to our baseline of recent prior projects,” says Martinoski. He attributes this in part to CarbonCure but also to Miller & Long’s mix design partner, Swope & Associates, which helped optimize mix proportions for each strength requirement.

“Concrete break results exceeded even my expectations by reaching 3,000 to 4,000 psi above the required strengths during the curing period,” Martinoski adds.

Miller & Long has finished level 17 of its building and has placed 94,000 cu yd of 110,000 cu yd. The job is on schedule to top out during the last week of March.

On the north building, Clark Concrete has completed placing level 18, or 80,000 cu yd of 90,000 cu yd of concrete. The job is on schedule to top out during the first week of April, says Matt Smith, a Clark Concrete vice president.

There was not enough space on the PenPlace site for a Clark Concrete batch plant. Instead, the sub procured the concrete from Vulcan Materials Co., a ready-mix supplier with a plant several miles away.

Clark Concrete did not use the ZGF tool. It reduced the GWP 10% to 30% from the National Ready Mixed Concrete Association baselines and Athena-produced job-specific EPDs for Vulcan, which uses CarbonCure. Major mixes replaced 15% to 25% of Portland cement with Newcem Slag Cement. The mat mix was 75% Newcem to control the mass concrete heat of hydration, says Smith.

Both subs prefer performance specs because they allow flexibility in meeting mix requirements, including reducing EC. “They allow contractors and suppliers the freedom to use proprietary material and means and methods to produce the most productive and cost-efficient product,” says Smith.

He classifies most ready-mix specs as performance-based because Clark simply dictates the ultimate strength of the concrete, for example 5,000 psi, and specifies the materials must meet ASTM requirements.

Though Miller & Long bids most of its work based on prescriptive specs, Martinoski senses the design community is moving toward performance specs. “We’re being engaged earlier in the design process and there is increasing interest in how we achieve” more sustainable concrete, he says.

Both contractors are pleased with the EC reduction and hope to implement it again. Smith, who has already used carbon-reducing strategies on several jobs, says it is becoming more common for owners to ask about it. Several recent bid requests, other than MetPark, even had EC-reduction targets, he says.

Complicated Logistics

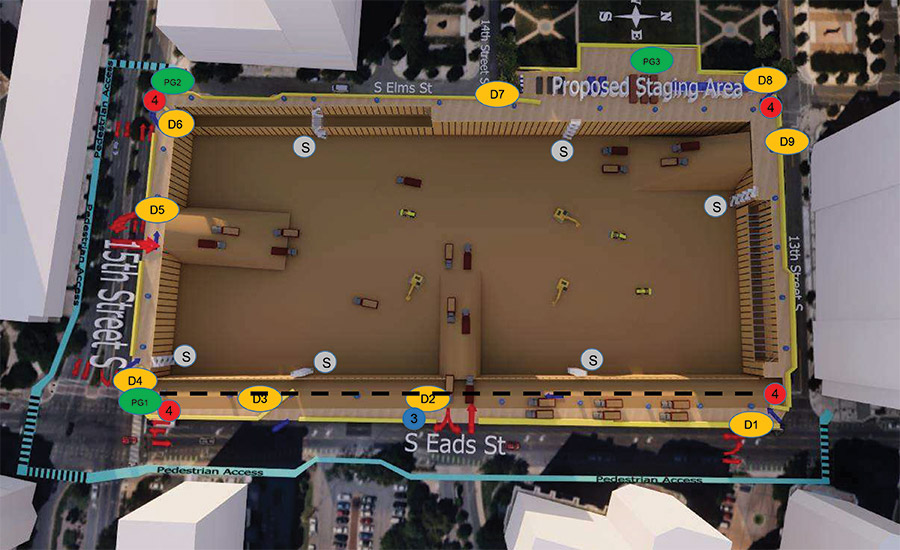

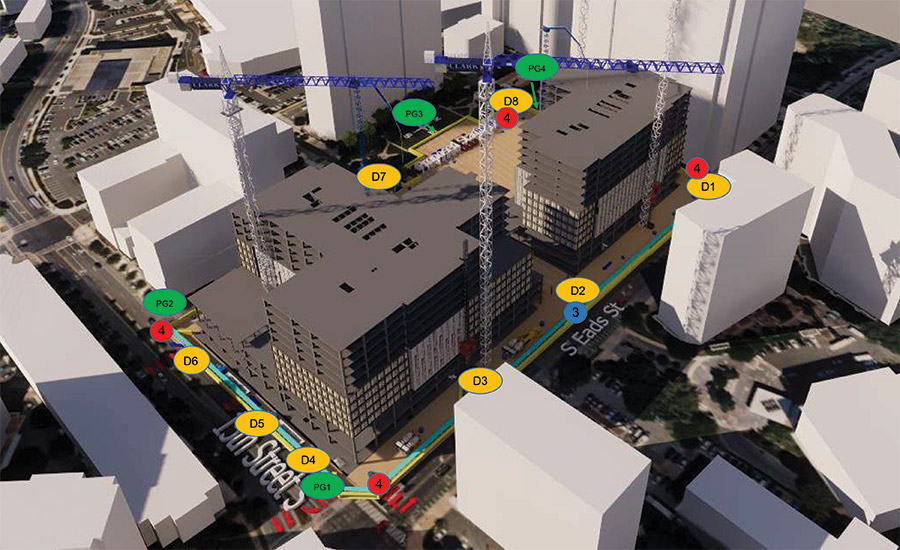

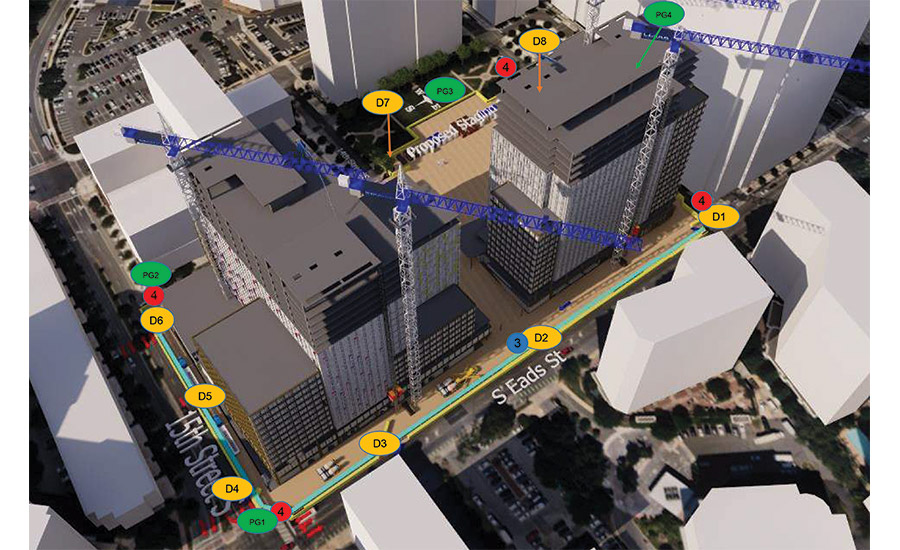

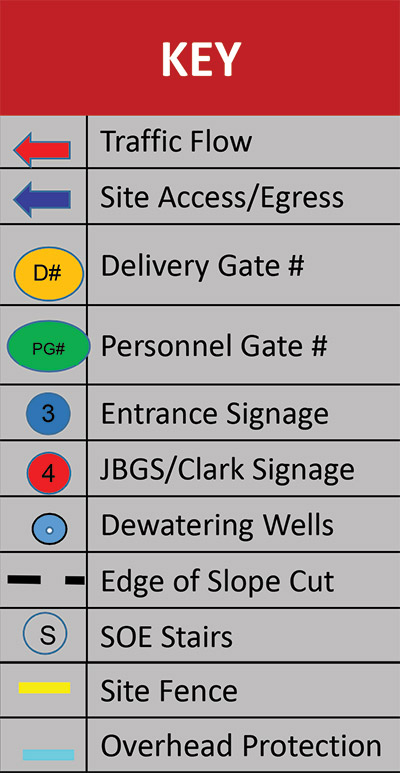

To deal with the complicated logistics, Clark Construction mapped out a detailed BIM-based work sequence, inputting restrictions. For example, the noise ordinance limits operations to 7 a.m. to 9 p.m. weekdays and 9 a.m. to 9 p.m. weekends and holidays. Crews would have placed the mat starting at 4 a.m., as is common, but couldn’t.

The 450,000-cu-yd excavation began in April 2020, as COVID-19 hit. Clark and its subs follow recommended pandemic protocols. There have not been any COVID-19-related shutdowns or worker deaths. The job is on schedule for substantial completion in the spring of 2023.

Clark ran the below-grade work as one job. During the peak of the excavating, there were 70 to 80 dump trucks, each making three or four daily runs in and out of the site. Clark staged the trucks both at the PenPlace site and at a lot a few miles away. “We did not want the trucks backing up on the local streets,” says King.

Miller & Long started casting the concrete, both pumped and bucketed, in the southwest corner in the early fall of 2020 and the last dirt came out of the pit at the northwest corner early that December. There are four concrete delivery stations near the corners of the site.

NBBJ designed the nearly four-year-old Spheres at Amazon’s HQ1 in Seattle (below) as a conservatory for tropical plants and the future Helix at PenPlace (rendering, above) as a double spiral of outdoor landscaped terraces that includes a hill climb.

Rendering courtesy NBBJ (above); Photo courtesy of Sounderbruce via Wikipedia (below)

Amazon’s Performance-Based Incentives

For its HQ2 investment, Amazon will receive direct performance-based government incentives of $573 million, determined by its projected creation of 25,000 jobs with an average wage of over $150,000. This includes a workforce cash grant from the commonwealth of Virginia of up to $550 million, based on $22,000 for each job created over a 12-year period. Amazon also will receive a cash grant from Arlington of $23 million over 15 years, based on the incremental growth of the local Transient Occupancy Tax on hotel rooms.

Virginia and Arlington will likely benefit from an estimated incremental tax revenue of $3.2 billion over the next 20 years, says Amazon, which also is supporting the region. The $2-billion Amazon Housing Equity Fund is helping maintain and develop affordable housing. And Amazon donated $1 million to four area foundations, including the Arlington Food Assistance Center (AFAC).

Amazon also is providing public outdoor green spaces and bike trails. And the future 350-ft-tall Helix, the centerpiece of PenPlace, will be open to the public.

As designed, the double-helix steel-framed building, inspired by a seashell or DNA, will have two spiralling outdoor terraces. One is a series of gardens and the other is a landscaped hill climb, says Dale Alberda, design principal for PenPlace’s NBBJ Architects.

The Helix, a 14-story atrium building, is purposely different from NBBJ’s iconic Spheres at Seattle’s Amazon HQ1, which opened almost four years ago. “We applied lessons learned on the Spheres to the Helix,” says Alberda, also HQ1’s design principal.

The three clustered glass-clad Spheres, as tall as 100 ft and reminiscent of soccer balls in shape, are more of a conservatory, with an interior environment that nurtures endangered tropical plants, says Alberda. The Helix’s atrium, which will contain indigenous plants, is designed first and foremost for human comfort, he adds.

ZGF and NBBJ collaborated on parts of each other’s HQ2 projects. The veteran of Amazon work sat in on some ZGF design meetings for MetPark to offer historical context. And ZGF advised NBBJ on PenPlace entitlements, which are expected in April. “Amazon HQ2 is the latest of many successful collaborations between ZGF and NBBJ,” says Earle.

Rendering shows the future three-office-building PenPlace in the northwest section of the village and the two-building MetPark, on course for substantial completion in the spring of 2023, in the south.

Rendering courtesy Amazon, ZGF, NBBJ

Clark Construction is currently in talks with Amazon about erecting the Helix, engineered by Magnusson Klemencic Associates. Meanwhile, Clark’s MetPark team remains a good neighbor, even beyond the job itself.

In a recent construction update, Clark wrote: “This December, we furthered our support of [AFAC] by hosting a food drive on the jobsite....We look forward to continuing our monthly volunteer events with AFAC next year, and to finding new ways to engage with and support the Arlington community.”

All Clark communiques end with an invitation: “If you have questions or concerns about ongoing or upcoming construction activities, contact our project team: metpark678@clarkconstruction.com.”