Transportation

Port of Long Beach OKs $170M Plan to Deepen Ship Channel

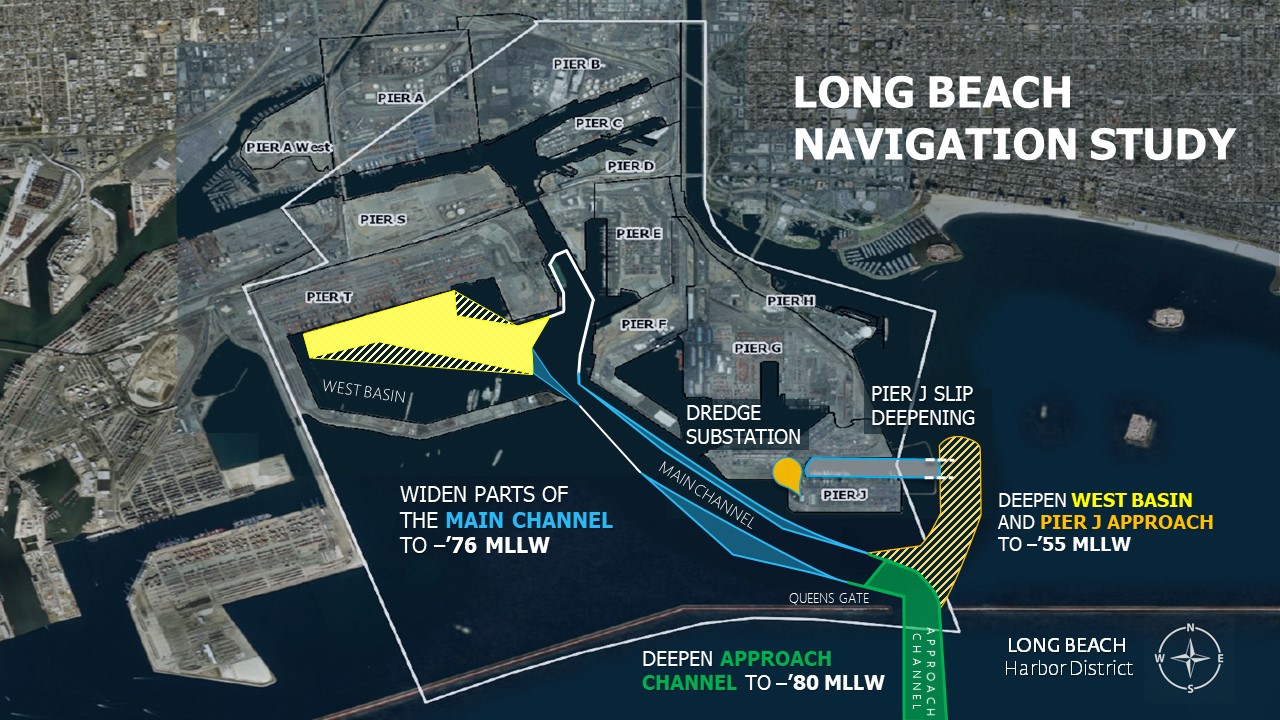

By deepening and widening the Port of Long Beach's waterways, the world's largest container ships can safely maneuver in and out of the port.

Photo courtesy Port of Long Beach

The Port of Long Beach's Board of Harbor Commissioners has unanimously approved an ambitious, $170-million effort to improve access to the port by widening and deepening its waterways.

Port officials say the proposed, $170-million Deep Draft Navigation Channel Deepening Project will give ships more room to maneuver efficiently and safely. It will deepen the Long Beach Approach Channel from 76 ft to 80 ft deep and remove 7.4 million cubic yards of sediment from the port’s various waterways.

“By improving navigation in Long Beach Harbor, goods will speed faster around the supply chain, yielding enormous economic benefits for our city, region and the nation,” said Harbor Commission President Sharon L. Weissman in the meeting.

The commissioners unanimously approved the project's environmental impact report on Sept. 12. In July, the U.S. Army Corps of Engineers issued a Record of Decision concluding the federal environmental review process for the project, clearing the way for federal funds.

The Port of Long Beach and the federal government will share the project costs, estimated at almost $170 million. The Port’s portion is estimated at $109 million.

Port officials will now seek the required permits and then move into the project's planning and design phases. Dredge operations could begin as soon as 2026 and will take approximately three years to complete, says Sean Gamette, the port's managing director of engineering.

Image courtesy Port of Long Beach

Long Beach ranks as one of the country's busiest ports, handling roughly $170 billion of cargo annually, according to the port. Some of the world’s largest ships enter the port, but tidal flows, weather and vessel size limit when they can drop anchor in Long Beach harbor given its current configuration.

When the dredging project is completed, the largest container ships will have increased access to the port while also carrying more cargo, which reduces the overall number of ship calls, instead of stacking fewer containers to clear existing channel twists and turns. Deeper, wider waterways will also reduce the need for lightering – the process tankers use to transfer their liquid bulk cargo to smaller vessels – so the bigger tankers have the under-keel clearance they need to enter the Port.

“We already accommodate some of the largest ships in the world here,” said Port of Long Beach Executive Director Mario Cordero in a news release. “Deepening and improving our waterways will give these vessels more room to maneuver, and to do so more efficiently by taking on more containers, reducing the number of ship calls and associated emissions.”

In addition to deepening the approach channel, the project would involve easing turning bends in the Main Channel to deepen a wider area to 76 ft, deepening parts of the West Basin from 50 to 55 ft, constructing an approach channel and turning basin to Pier J South with a depth of 55 ft, improving the breakwaters at the entrance to Pier J, and depositing dredged material in nearshore sites for refuse or in federally approved ocean disposal sites.

“With a project like this, nearly all of the work happens on the seafloor,” says Gamette. “It requires specialized equipment that can reach 80 ft below the water surface to remove sediment and move it to another location that is potentially miles away. It requires sophisticated surveying instruments to guide subsea excavation to ensure that the desired depth is achieved while not removing material beyond what is permitted.”

The dredges on the project employed within Queen’s Gate will be powered by electricity using miles of cable connected to a shore-side substation built for this purpose. The project also requires the installation of subsea structures to maintain the stability of existing dikes, breakwaters and wharves as the sediment around them is removed, deepening channels and ship berths.

The port intends to reuse as much of the estimated 7.4 million cubic yards of sediment to create new land within the Port as well as include replenishing sand on beaches along the coastline. If used to enlarge port space to promote construction of leasable terminal space, the dredged material would save the Port tens of millions of dollars, port officials say.

The project also has environmental benefits. More efficient maneuvering means ships burn less fuel as they transit the harbor, as do the port pilot vessels and tugs that escort them. Greater efficiency lowers ground-level pollution – diesel particulate matter, nitrogen oxide and sulfur oxide emissions – from ships, one of the largest sources of these pollutants associated with port operations.

![Pier B rendering[97] copy.jpg Pier B rendering[97] copy.jpg](https://www.enr.com/ext/resources/2024/03/11/Pier-B-rendering%5b97%5d-copy.jpg?height=200&t=1710191370&width=200)