East Africa Could Face Challenge of Multiple Railway Gauges

Construction of the $3.6-billion double-track standard gauge railway (1,435mm) linking Kenya’s Indian Ocean port city of Mombasa to the capital Nairobi could pose a fresh challenge for railway operators in East Africa interested in connecting with the modern rail line.

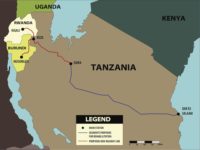

Railway transport experts say the 609-kilometre high speed railway line is being constructed in a region where existing railway gauges are predominantly meter-gauge (1000mm) and cape gauge (1067mm). Kenya and Uganda operates 2,351-kilometres of meter gauge rail network while Tanzania operates 2,600-kilometers of both meter gauge and Cape gauge. It may need additional investments to harmonize the gauges to enable a seamless intermodal rail transport in East Africa.

To integrate the standard gauge railway line, set to be completed in 2018 under a contract by China Roads and Bridges Company, it may require conversion of the existing gauge or transshipment, where containers and passengers from Mombasa en route to Uganda, Rwanda, or Burundi would have to be transferred from railroad cars on the standard railway gauge to another on the meter gauge, which links Nairobi to Kampala. The new modern railway is being built alongside the existing 100-year-old Kenya/Uganda Railway line, currently run by a concessionaire, Rift Valley Railways.

"The alternative could be for the East and Central Africa countries to run dedicated meter-gauge and standard gauge railway lines running from single origin to single destination if they do not need to harmonise the gauges,” said Heiko Ifland, senior consultant with Germany-based railway consulting and engineering firm Railistics.

The current railway network in the region is unable to meet the growing demand for increasing freight such as fuel, containers, bulky goods and raw materials, he said during the 5th East and Central Africa Infrastructure Summit in Dar es Salaam on August 27th. That's because “the infrastructure was built in colonial era to meet the requirements of respective colonial power and which could be served well with a narrow gauge lines. Whether the countries decide to go for the standard gauge or improve on the existing narrow gauge depends on what they want to carry but for them to increase intra-Africa trade there is need for coordinated logistics corridors,” he said.

Nathan Reese, vice president for engineering at Amsted Rail, based in Chicago, said the multiple rail gauges in Africa provide an opportunity for companies like Amsted to expand technological solutions to meet the need for harmonisation of the gauges, such as the high performance/low maintenance bogie systems “which the railway industry is looking to for the improvement of rail, wheel life and low life cycle costs.”

He said railway operators in Africa, just like in Europe and the rest of the world, well utilized railway capacity is critical and can be achieved through having longer trains, heavier axle loads, increased train velocity, more lading capacity, light railcars and paying more attention to load balance and vehicle stability in addition to “speed and track conditions, and railcar construction."

Railroad Association of South Africa chief executive officer Mr John Thompson, said East and Central Africa region stands to benefit more from a standard gauge railway system because it “is more stable and therefore can accommodate more of the anticipated increase in freight”.

He said the current narrow gauge (both meter and Cape) were not built to technical standards and can accommodate maximum axle loads of between 16 tonnes to 18 tonnes, yet the region is currently moving freight requiring maximum axle loads of 25 tonnes.

“With a standard gauge railway it is possible for one to have twice the load that he could in a metre gauge, can move at high speed because the wider the gauge the more comfortable the ride and can also run heavier axle loads,” he said.

“Kenya, Tanzania and Uganda may have a challenge carrying heavier loads on their current narrow gauge. If they want to do it, they have got to increase axle loads, change the rail and probably change the sleepers because they were not built for that kind of load. They could also convert the gauge or better still run more trains/hour which means they have to change their signalling system,” explained Thompson.