Bridges

Unique Suspension Bridge Takes Shape in Linz, Austria

Deck sections over water were lifted from barges, but on the river banks the last sections were assembled on platforms over the highways.

Photo courtesy of ASFINAG

Each suspension cable is formed by six rows of two cables held by steel clamps.

Photo courtesy of ASFINAG

Completed deck modules were delivered by barge for installation.

Photo courtesy of ASFINAG

View across the emerging bridge from the north tunnel portal approach last May.

Photo courtesy of ASFINAG

Tunnels connecting riverside roads with the bridge are part of the contract.

Rendering courtesy of ASFINAG

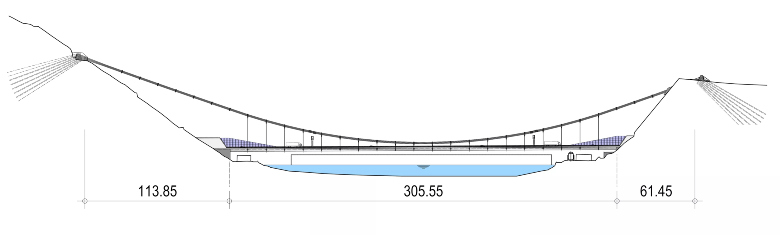

Being as invisible as possible was a key requirement for the suspension bridge emerging between the verdant south side of the Danube valley in Linz, Austria, and an up-market community on the other. Supported by cables anchored into the valley sides, the last two sections of the 1,000-ft-long deck are due to be placed this week and next.

As the bridge takes its shallow shape, the Italian-led joint venture is also completing 2 miles of new, tightly curving drill-and-blast tunnels through the valley sides to link riverbank highways with the new crossing.

To carry the A26 Linz western bypass over the busy waterway, the steel composite deck will be suspended by large cable clusters stretched between anchorages in the valley sides. More than 200 rock anchors, drilled with meticulous accuracy up to 230 ft into the ground, are holding down the complicated anchorages.

"We have a unique bridge, where all the loads are located right above the tunnel," says Franz Sempelmann, project manager with the state's toll road owner ASFINAG Bau Management GmbH. On the north side, "there [are] only 10 meters from the tunnel to the [ends of the] anchors of the bridge abutment...the bridge and tunnel are not allowed to influence each other," he adds.

Planned over many years by local authorities, the project lay dormant till ASFINAG took over some 15 years ago, providing most of the financing, says Sempelmann. To spread the investment over time, ASFINAG divided the project into three, starting with the bridge and linking tunnels. Another 2.9 miles of southbound tunnels to the main railroad station and beyond, plus a bridge will complete the program in two subsequent phases, probably starting in 2025, says Sempelmann.

Stretching 1,640 ft between anchorages, the suspension cables of the bridge support 20 pairs of hangers spread at 47.7-ft centers along the deck edges. The roughly 72-ft-wide concrete-topped deck comprises an 8-ft-deep trapezoidal box spine varying in width from 16 ft to 23 ft. Cross girders taper out from the spine to connect with 3-ft-deep edge beams and hanger anchorages.

A team led by German structural designer Schlaich Bergermann Partner (SBP) won the bridge's design competition nearly 20 years ago, offering the only structure without intermediate supports, says Sempelmann. A conventional bridge was not feasible “in this very sensitive…dense valley [bordered] by roads and railways,” explains Mathias Widmayer, SBP's construction engineering director.

Courtesy of ASFINAG

Courtesy of ASFINAG

Because of their shallow sag, "huge tension forces” are needed in the suspension cables, says Widmayer. Each cable comprises six stacked pairs of 5.7-in.-dia spiral locked coil cables held by cast steel clamps, which are about 6.6 ft tall.

Each of the 12 cables is fixed to a steel projection from elaborately shaped concrete anchor blocks. On the south side, the block is cut into the steeply inclined valley side. On the north, the contractor cut through the top of the valley wall to move the anchorage further back to better rock, but also close to homes. Both anchorages lie directly above tunnel ends.

Fixing suspension cables to the south anchorage early last year. Photo courtesy of ASFINAG

Fixing suspension cables to the south anchorage early last year. Photo courtesy of ASFINAG

To procure the project, ASFINAG invited separate offers for the tunnels and bridge, allowing bidders to combine the two. Joining both elements "was the best...decision we ever made," says Sempelmann. With two contractors working in cramped conditions by riverside roads and a railroad "the interfaces would have been terrible."

The successful Italian-led joint venture started work on its 49-month, cost reimbursable contract in January 2019. The team includes the medium-sized local firm F-Pile GmbH and Italy's Gruppo ICM SpA, which are handling tunneling and civil work. The third partner, Maeg Costruzioni SpA, is responsible for the steelwork.

Building the team was "really difficult at the beginning," says Bernhard Watzl, the joint venture's bridge project manager. The companies hadn't known each other, and Austria had no modern experience of large highway suspension bridges, says Watzl. And having the contract in German added to the cultural challenges. "All the engineering and the headquarters were actually in Italy," says Sempelmann.

Originally valued at $143 million, the contract cost has risen substantially, says Watzl. He cites difficult excavations among the causes. And “our price was too low...In the Austrian system you only get the contract when you give them the best price,” he says. Work is also running some six months late, largely because of pandemic lockdowns, says Sempelmann.

Lack of space and limited work hours demanded by nearby residents added to the challenges of building the anchor blocks, says Watzl. The multifaceted blocks containing rock anchors on one side, suspension cable fixings on the other and prestressing in between needed to be shaped with special formwork from Doka Österreich GmbH. The supplier "said to me this was the most complex formwork they had ever made worldwide,” he adds.

Elaborate formwork was needed for the north anchorage in late 2020. Photo by Doka Österreich

Elaborate formwork was needed for the north anchorage in late 2020. Photo by Doka Österreich

With anchorages done, the contractor placed the 24 cables forming the main suspenders in the first half of 2021, says Watzl. Set about 16 ft apart at anchorages, the cables are forced apart with temporary hydraulic struts in curving profiles to a maximum exceeding 65 ft at mid span.

When the inclined hangers and full deck are in the place, "the entire structure is that stiff that we can remove the temporary struts," says Sempelmann. Also, curving cables combined with inclined hangers "gives us a little bit more stability in the transverse direction,” adds Widmayer.

With the main cables and hangers placed late last year, the contractor’s plan to start deck erection was delayed by missing barges. Before the barge contract was inked, the operator diverted its vessels to ferrying goods to Ukraine, say Watzl. With alternative barges procured and remodeled, erection began three weeks later in early December, he adds.

Deck sections over water were lifted from a barge by strand jacks. Photo courtesy of ASFINAG

Deck sections over water were lifted from a barge by strand jacks. Photo courtesy of ASFINAG

Maeg fabricated deck steelwork in girders and boxes up to 44 tons at its facility at Vazzola, north of Venice. They trucked them close to a riverside site near Linz to be welded into seven complete deck modules weighing up to 309 tons. Barges then carried the modules to the bridge to be lifted with strand jacks into position over the river, raising the final one on Jan. 26.

For the deck's 150-ft- and 200-ft-long end sections, which are not over water, the contractor assembled the modules on temporary platforms covering the highways. Using mobile cranes, it plans to place the southern module this week and the northern next.

.jpg?height=200&t=1654624305&width=200)