Ford Motor Co. plans to spend $3.5 billion to build an electric vehicle component plant in Marshall, Mich., which it says would be the first U.S. automaker-backed facility to produce batteries made of lithium iron phosphate.

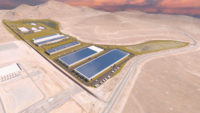

A Ford spokesperson says the automaker is now sourcing firms for design and construction of the plant, which it named BlueOval Battery Park Michigan and plans to have on line in 2026. The facility would have a 35-GWh capacity, enough to produce batteries for about 400,000 EVs each year.

A wholly owned subsidiary of Ford would manufacture battery cells at the plant with assistance from Chinese battery maker Contemporary Amperex Technology Co. Ltd, also known as CATL. Ford and CATL announced agreements last summer to cooperate on battery technologies, and for the Chinese firm to supply Ford with lithium iron phosphate battery packs for the automaker’s electric Mustang Mach-Es starting this year and for its F-150 Lightning next year.

The battery is more durable and uses less high-cost material than the nickel cobalt manganese battery, although the latter can handle longer distances between charges and offer better cold-weather performance, according to Ford. Charles Poon, its global director of electrified systems engineering, says in a statement that offering both types of batteries allows drivers to choose which best meets their needs.

But the link with Chinese technology has prompted congressional and state official concern. Virginia had been in contention to site the facility, but was withdrawn by Gov. Glenn Youngkin (R) in December. "We felt that the right thing to do was to not recruit Ford as a front for China to America,” he told reporters in January after his annual State of the Commonwealth speech.

Senate Energy and Natural Resources Chair Joe Manchin (D-W.Va) "has been clear about his grave concerns about vehicle supply chain reliance on China. Ford has serious questions to answer before Senator Manchin can fully evaluate the business partnership,” said a spokesperson on Feb. 14.

China also is reviewing the deal, citing competitive concerns, said a Bloomberg report.

“We certainly thought through that and those are provisions and things we’ve agreed with CATL in the course of our contract work,” Lisa Drake, Ford vice president of EV industrialization, told reporters. “Of course we thought about it and we’ve taken care of the optionality with that in the contract.”

Noting that “It’s really important to understand that Ford controls the plant,” she said CATL employees will assist in factory setup, but Ford "will operate the facility. It will be a Ford plant manager.”

Ford is currently building two other EV battery plant projects as part of a partnership with South Korean battery maker SK Innovation Co.

Detroit-based Walbridge is the general contractor for the $5.6-billion Blue Oval City manufacturing complex in Stanton, Tenn., which would include both battery and EV production. A team led by Southfield, Mich.-based Barton Malow and Lexington, Ky.-based Gray Construction is building the $5.8-billion, two-plant Blue Oval SK Battery Park in Glendale, Ky.

Ford says it aims to produce 2 million EVs annually by the end of 2026.