Manufacturer Entek picked Clayco as the design build contractor for a planned $1.5-billion plant to produce electric-vehicle battery components in Terre Haute, Ind., the companies announced April 20. Work is expected to start later this year or next year. Entek anticipates beginning operations between 2025 and 2027.

Chicago-based Clayco is providing design, engineering, procurement and construction services. It is also self-performing concrete work, including foundations, flatwork, tilt-up wall panels and paving. The contractor says it expects about 400 workers to be involved in construction at peak.

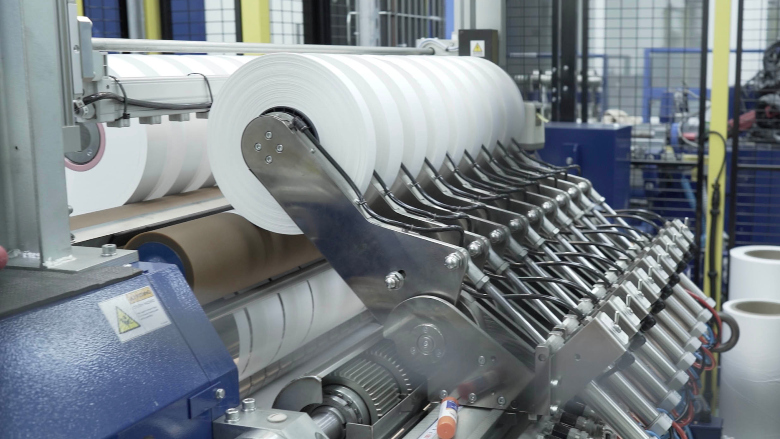

Entek plans to produce lithium-ion battery separators at the plant. The company says it is the only producer of “wet-process” separators—components used in electric vehicle batteries—with U.S. owners. Entek aims to provide components to support between 1.4 million and 1.6 million EVs annually by 2027.

The project is in the wake of the 2022 Inflation Reduction Act. The law includes clean vehicle tax credits as part of Biden administration goals for reducing greenhouse gas emissions. To be eligible for the IRA tax credit, a maker must manufacture or assemble 50% of EV battery components in North America. That increases each year to 100% in 2029.

Entek’s project is being supported by a $200-million grant from the U.S. Dept. of Energy via the Infrastructure Investment and Jobs Act, which set $2.8 billion for expanding facilities to process EV battery materials and manufacture components.

Larry Keith, CEO of Entek, said in a statement that the project would “have positive impacts on the local and larger economy, as well provide a key component required for the electrification of vehicles to further US climate goals.”

Clayco, which ranks No. 16 on ENR’s 2022 Top 400 Contractors list, has worked on a variety of other plants for the EV supply chain. The contractor is currently working on a project for Group14 Technologies in Moses Lake, Wash., that the owner says will be the world’s largest commercial plant for advanced silicon battery materials. The first two modules, of six planned for the plant, are expected to open in 2024.