ENR 2023 New England Best Projects

Best Project Renovation/Restoration: Union Mills 37

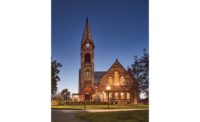

Photo by Elisif Brandon, Elisif Photography, courtesy Timberline Construction Corp.

Union Mills 37

Attleboro, Mass.

BEST PROJECT

Submitted by: Timberline Construction Corp.

Owner: 37 Union St. Attleboro LLC

Lead Design Firm: Davis Square Architects

General Contractor: Timberline Construction Corp.

Civil Engineer: Crossman Engineering

Structural Engineer: Souza, True and Partners Inc.

MEP Engineer: BLW Engineers Inc.

Subcontractors: Emond Plumbing & Heating Inc.; Superior Drywall Inc.

The project featured the redevelopment of a century-old mill complex into 59 apartments next to a commuter rail station on a line connecting Boston and Providence, R.I.

The renovation and adaptive-reuse of the multibuilding complex required meticulous attention to detail. The site, long named the Foster Buildings, had been home to a jewelry factory and was on the Massachusetts Register of Historic Places.

Replica windows were installed, while modern amenities have been “seamlessly integrated into the structure,” according to the project team.

Along the way, the team overcame some significant challenges, including a storm that ripped off roughly one-third of the walls of the complex as well as the roof on the fifth floor before construction even started. As part of the project, the section had to be reconstructed with the help of historic consultants to ensure that new materials complemented the building’s historic facade.

Photo by Elisif Brandon, Elisif Photography, courtesy Timberline Construction Corp.

That was hardly the only major obstacle the team overcame. The interior columns in the lower level of the building rested not on proper footings, but on large rocks. That posed a structural risk and complicated the work of the construction and design teams. To address the issue, they developed an approach to shore up the building to keep it stable during construction by removing the slab on grade.

Crews also undertook the complex task of removing the lower level of all 16 columns and footings, which required careful execution and top-notch engineering expertise, according to the project team.

In addition, the team had to grapple with uneven flooring throughout the building. The option of leveling the floors by filling them was ruled out due to concerns that it would create an excess load. Instead, the project team was able to almost bring the floors to flat condition and make them near level by rolling out a combination of insulation and gypcrete.

According to the team submission, the use of such lightweight materials, along with careful calculations, enabled the team to keep at a minimum additional strain on the historic structure while adjusting and transitioning the subfloors.

The team says it was also able to draw upon its collective expertise and skill honed over many years to explore options and analyze the various structural and design challenges that arose during the construction process. The team says its overall adaptability and efficiency under pressure was a major plus.

Photo by Elisif Brandon, Elisif Photography, courtesy Timberline Construction Corp.

Effective communication between the owner and the construction team, the structural engineers and architects helped minimize the impact of supply chain issues, the participants say. The team says unforeseen supply chain disruptions caused the approximately 18-month-long project to deliver behind schedule, but with owner approval of that delay.

Adjustments in resource allocation and procurement strategies, along with effective communication between the project team and owner, “ensured transparency and collaboration throughout the process,” the team says.

The team declined to disclose the project’s construction value but said the work was finished at budget.