Bechtel and Purdue University are testing out a budding HVAC technology that could cut the energy expended on air conditioning by 5% across the board.

The National Renewable Energy Laboratory estimates that 1,950 million tons of CO₂ are released annually—roughly 3.94% of global greenhouse gas emissions—to control temperature and remove humidity with air conditioning systems. What if some of the energy wasted during air conditioning could be recaptured, allowing an HVAC system to partially run off its own expended energy, similar to a combined-cycle gas-fired power plant running off its own steam? Bechtel is exploring this possibility with Crescendo, a technology that uses a “regenerative” cooling cycle to captures some of the energy lost by current HVAC systems. The system is being tested at Purdue University.

“What we’re really excited about is the broad applicability of this technology. It has wide applicability to all sorts of sectors,” says David Ladd, a solutions manager in Bechtel’s manufacturing and technology group in Houston. Ladd invented Crescendo in 2015 and has been refining it since. “Data centers is one [possible application], but [it could go] all the way down to small applications such as single-family homes.”

Ladd and the Purdue team’s research was published in the peer-reviewed Proceedings of the International Congress of Refrigeration in September. The paper explains that “the benefit achieved by better refrigerant distribution is quantified by a slightly different pinch point temperature in this paper, and the results show near 5% of power savings can be made possible.”

The pinch point is the temperature difference between a refrigerant and surrounding air. The technology could enable use of less-toxic refrigerants that emit fewer greenhouse gases or even using CO₂ as a refrigerant rather than the hydrocarbon-based ones in use today.

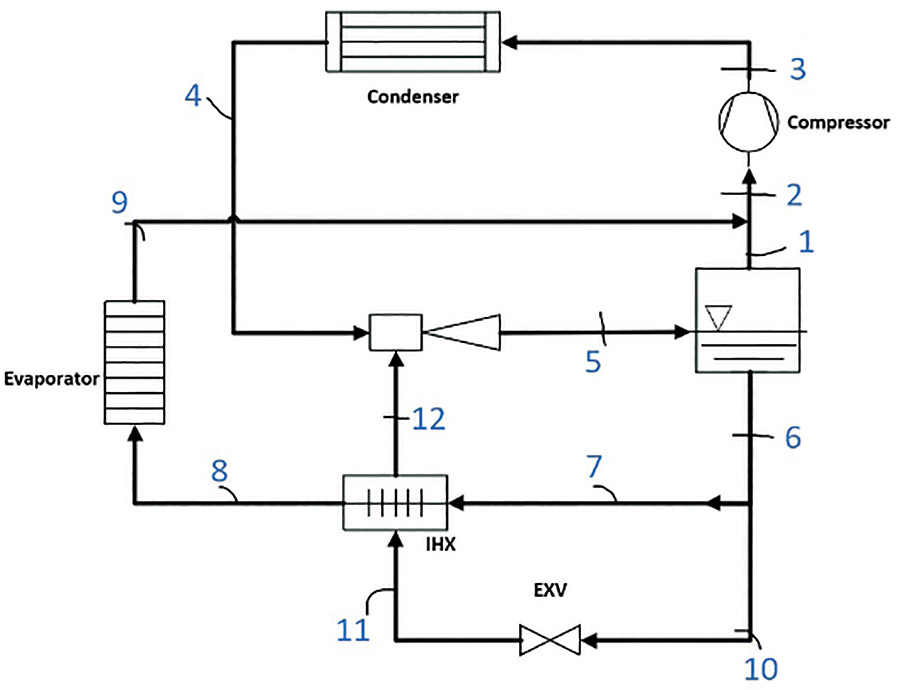

This diagram shows Bechtel’s single-compressor, ejector and evaporator layout.

Illustration courtesy of Bechtel

*Click the image for greater detail

A working prototype of the Crescendo system is being tested in a building on the Purdue campus in West LaFayette, Ind., as part of the ongoing research.“[Purdue University’s] Herrick Laboratories are at the forefront of assessing emerging refrigeration technologies,” said Dr. Davide Ziviani in a statement. Ziviani is an assistant professor of mechanical engineering and co-principal investigator of the Crescendo project at Purdue along with Dr. Eckhard Groll. “The collaboration with the Bechtel team led to the development of a state-of-the-art hydrocarbon-based experimental setup to demonstrate the feasibility of the technology,” he said.

Bechtel is also continuing research in its manufacturing and technology group. “David [Ladd] is a great example of an entrepreneur that’s really an intrapreneur that we’ve been able to encourage through our focused effort internally on developing new solutions and technologies,” says David Wilson, principal vice president and solutions manager at Bechtel. Development of Crescendo and other technologies will allow Bechtel to not only expand its offerings to clients, but enhance the company’s knowledge base for advanced manufacturing projects, such as semiconductor fabrication plants and battery production facilities.

Ziviani said the ongoing testing at the prototype facility and further research are still necessary before Crescendo can be deployed commercially. “Additional research is needed to optimize the cycle and its components,” he said. “The initial promising results can open the doors for next generation environmentally-friendly refrigeration systems for many applications.”