Best of the Best

Project of the Year: Microsoft Thermal Energy Center Showcases Geothermal Heating and Cooling

March 7, 2024

Best of the Best

Project of the Year: Microsoft Thermal Energy Center Showcases Geothermal Heating and Cooling

March 7, 2024Microsoft’s East Campus Modernization central utility plant is the tech giant’s symbol of its commitment to sustainability. Pump skids and other equipment were prefabricated.

Photo by Sean Airhart/NBBJ

Microsoft Thermal Energy Center

Redmond, Washington

Project of the Year

Submitted By: GLY Construction

Region: ENR Northwest

Owner: Microsoft

Owner’s Rep: OAC Services Inc.

General Contractor: GLY Construction

Lead Design Firm: NBBJ

MEP Engineer: Affiliated Engineers Inc.

Structural-Civil Engineer: Coughlin Porter Lundeen

The Microsoft Thermal Energy Center, a groundbreaking geothermal heating and cooling system that serves the buildings of the tech giant’s 72-acre East Campus Modernization outside Seattle, was truly two exotic jobs wrapped into one. Yet thanks to the synergy of collaboration, virtual design and construction, modular delivery and carbon reduction, the TEC team has set an example for smart sustainable project delivery that can be applied to many building types.

The heart of the TEC is the two-story central utility plant—on permanent exhibit as a symbol of Microsoft’s global sustainability commitment. Seventy-five percent of the plant’s mechanical and electrical equipment was prefabricated offsite in controlled environments.

The drastically different and most daunting part of the TEC is its 6.5-acre geothermal well field, consisting of some 900 bores drilled in the blind through unknown territory, mostly to 550 ft. Think of the well field as “a giant buried heat exchanger,” says Robby Oylear, project manager for the mechanical-electrical engineer, Affiliated Engineers Inc. Of AEI’s 15 completed geothermal systems, Microsoft’s is the largest.

Crews built the utility plant’s structure around its mechanical equipment.

Photo courtesy GLY Construction

The well field presented obstacles because the subgrade is strewn with remnants of buildings past and boulders, cobble and rock—none documented. The system also had to be built around existing utility lines and future utility lines, for other campus projects. “The subsurface conditions were a challenge,” says Ben Hamm, a senior project manager for general contractor GLY Construction.

The TEC plant was built from August 2020 to the end of June 2022; the geothermal system from February 2020 to March 2022. In spite of the obstacles, the team completed the project on time and under budget, reports GLY. Microsoft is not releasing the cost or any related details.

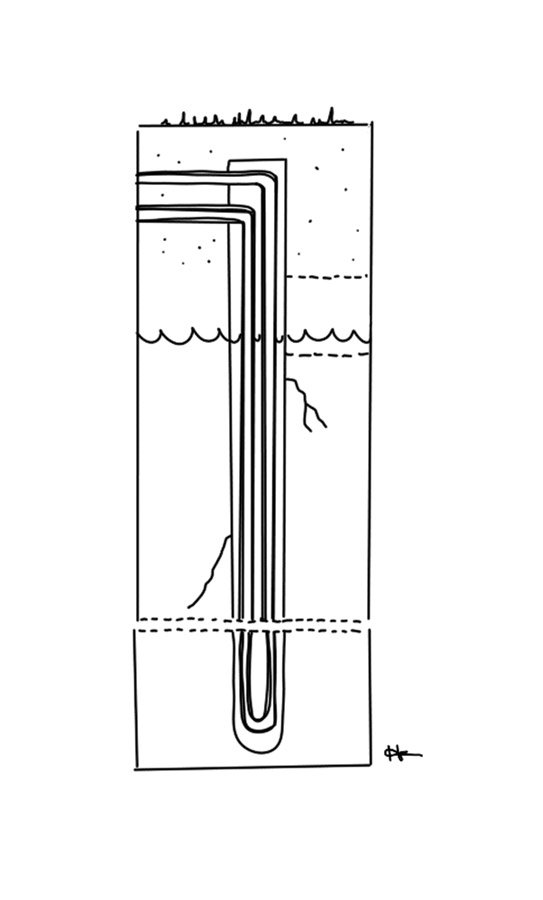

The closed-loop geothermal heating and cooling system sends either cool or warm water to exchange energy with the deep earth. The field has 6-in.-dia wells that each contain a water-filled pipe loop that absorbs the earth’s energy. The wells are connected at their tops, a minimum 6 ft below grade, by transverse piping to the 63,726-sq-ft central utility plant.

In addition to elbow grease, all credit the project’s success to a carefully choreographed effort that relied on team-wide collaboration and cooperation. This included a preconstruction phase for GLY and design-assist contracts for MacDonald Miller Facility Solutions for mechanical systems and Valley Electric. Some $15 million in savings came from value-engineering out redundant mechanical equipment, which likely would not have happened without design-assist, says AEI’s Oylear.

Rigs plowed through boulders, rocks and other obstructions, which slowed drilling productivity. In 25 of 900 cases, they could only drill down 400 ft and had to find other locations for 150-ft-deep wells.

Photo courtesy Dan DeLong for Microsoft

Virtual design and construction supported the activities. This included a 3D model detailed to 256th of an inch that became a digital twin, says Mike Green, building systems director for OAC Services Inc., the owner’s rep. A consolidated BIM execution plan, which laid out the project’s standards, was critical, he adds.

“BIM was the single source of truth for design and construction,” agrees Chris Beza, a principal for the architect NBBJ. “It was a game-changer for us,” adds Tim Brockway, a principal for the project’s civil engineer, Coughlin Porter Lundeen, also the structural engineer.

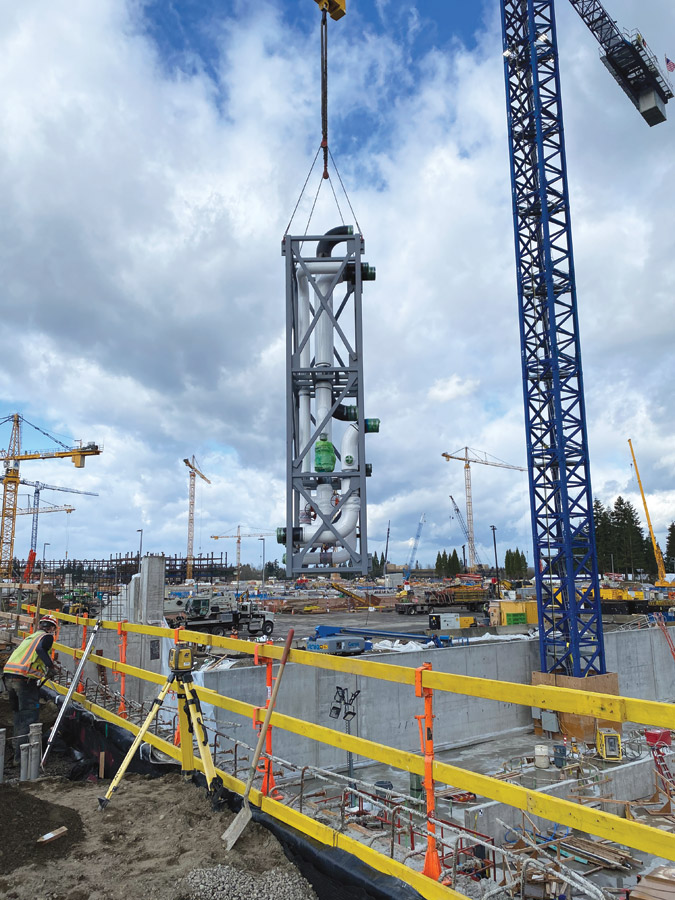

Offsite construction buoyed quality and safety and minimized fieldwork. For example, each steel-framed pipe riser represented six weeks of labor in the field but only took 10 days of work in a controlled environment, says GLY’s Hamm.

At the TEC, mechanical and electrical systems took precedence, which is a flip-flop. For example, the steel structure was built around the equipment. The steel erector had two 30-ft-square leave-outs in both the second level and roof of the two-story building to allow cranes to fly in the pump skids. Then, the erector returned to fill in the structure. Steel contractors prefer to mobilize and demobilize once.

The geothermal system exchanges energy from the earth’s depths through looped piping in wells.

Illustration by Hannah Olson

The combined strategies resulted in only 247 RFIs from the issuance of construction documents to commissioning, says Green. “There could easily be 2,000 RFIs for a project of this scale,” adds Green, who says each RFI cost $1,080.

The TEC’s heating capacity is 28 million Btus per hour. Its nine chillers can provide 9,000 tons of refrigeration. The system is sized to serve 3 million sq ft of office and amenity space in 17 new buildings, four of which are not yet built; two existing office buildings; and an underground garage at the Redmond, Wash., campus.

The well field is currently covered up by cricket and softball fields, basketball and pickle ball courts, roads and landscaping. Other contractors on the campus “successfully installed all of the [surface] elements after us, without any damage to date to the geowell system,” says GLY’s Hamm.

Work on the 6.5-acre geothermal well field could only be done a section at a time, in small zones borrowed from other contractors on the campus modernization project. That reduced productivity.

Photo courtesy Dan DeLong for Microsoft

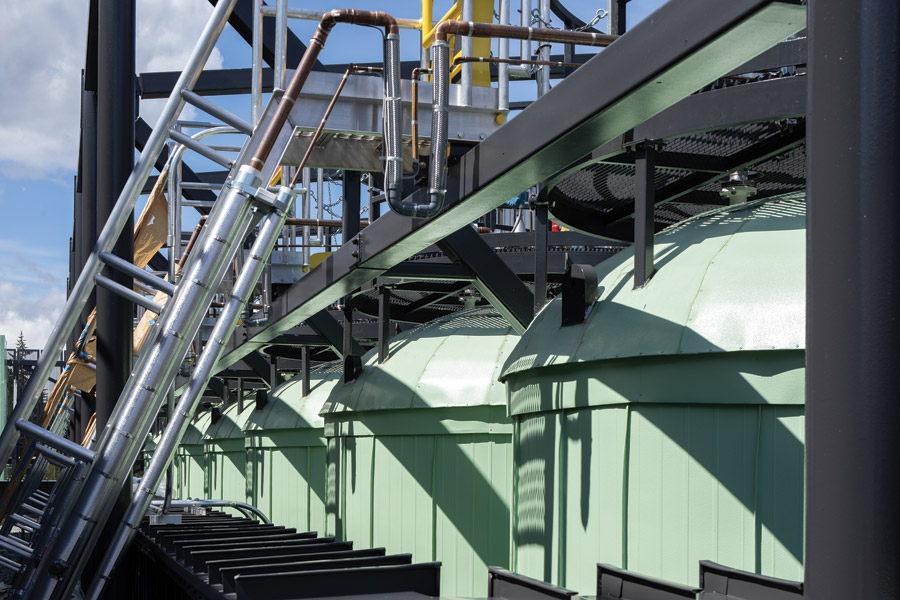

The TEC’s plant, which in addition to chillers, pumps, risers and electrical equipment for the geothermal system, includes emergency generators and other components, is paired with 280,000 gallons of thermal energy storage at maximum capacity, in seven tanks alongside the building. The water is distributed across four hot- and three cold-water storage tanks, each 65 ft tall and trucked in from across the country. A distribution system connects to the buildings to complete the heating and cooling system.

The primary role of the tanks is to allow the TEC heating and cooling equipment to operate in the most efficient way possible, rather than it having to respond to immediate changing needs of the campus, according to AEI.

Each of the seven 65-ft-tall thermal energy storage tanks was trucked to the site from across the nation and flown into position alongside the central utility plant.

Photo by GLY Construction

The closed-loop geothermal system consists of 24,000 lineal ft of water-filled plastic pipes in the deep geowells. The well piping is itself looped—one side for supply water and the other for return water (see sketch, opposite page).

The rationale for geothermal energy exchange as the main component of the heating system was based on the campus’ open green space, says Oylear. Though not the least cost solution up front, geothermal does ease the burden on the electrical utility, which saves on operating expenses, he adds. It is “very durable and resilient” and is highly efficient when compared to the base option of electric resistance heat/hot water boilers, says Oylear.

The project’s thermal energy storage tanks, four for hot water and three for cold water, contain a total of 280,000 gallons at their maximum capacity.

Photo by Sean Airhart/NBBJ

Operationally Carbon Neutral

Operationally carbon neutral thanks to renewable power sources, the TEC aligns with Microsoft’s global sustainability goals, which include becoming carbon negative and water positive by 2030. The project also incorporates about half the embodied carbon in construction originally predicted by the team, thanks to the use of the Embodied Carbon in Construction Calculator (EC3), released in 2019 and available for free download on the Building Transparency website.

One example of carbon reduction in transportation is the fuel for the TEC’s waste-hauling trucks—renewable biodiesel, made from repurposed fats, used cooking and inedible oils. GLY bought the fuel in bulk from Oregon and stored it in a tank onsite.

Pipe riser on its way into position was among 75% of the plant’s prefabbed components.

Photo by GLY Construction

Microsoft is using all the campus modernization projects as a coordinated pilot project to improve EC3, which allows teams to compare the embodied carbon in major construction materials and systems, from mining through construction. So far, the campus-wide EC3 pilot has been “a resounding success,” said Jeff Rovegno, senior development manager for Microsoft Real Estate & Facilities, in an email to ENR. “We integrated the tool into the modernization project’s core strategy with the five architects, three general contractors and multiple structural engineers, and are on track to reduce our embodied carbon footprint by a targeted 30%,” Rovegno added.

Microsoft expects the EC3 pilot to ease the way for teams all over to use EC3 to reduce embodied carbon. “We believe EC3 can drive broad improvements across the entire” construction industry, says Rovegno.

Offsite construction also reduces embodied carbon, in part because there is less waste in a factory environment, fewer deliveries and crew trips to the site and a shorter site schedule.

For owner’s rep Green, the TEC plant presented a rare opportunity to “set the table” to realize the potential of modular delivery for mechanical and electrical equipment. At an early team meeting on modular, “I saw the eyeballs of the design-assist ME trade partners get really big” with excitement, says the 40-year construction veteran, with a strong penchant for prefab because he came up through the trades as a pipe fitter. ME subs, eager to prefabricate, are often frustrated by a reluctance on the part of designers and contractors to embrace modular, especially in commercial development, Green has learned.

A validated BIM also empowered the ME trade partners to commit to more prefab than is usual, says Green. For modular to work, the TEC “had to be built first virtually, to perfection, and then followed up by verification,” in the physical world, adds Green. On the TEC, “QA-QC was not just lip service.”

GLY built its construction BIM by overlaying it on the highly refined design model. At the end of design development and the beginning of CDs, MacDonald Miller took over spatial coordination in the model. Clash detection was done weekly.

The strategy worked. The first prefabbed module was set within an allowable ⅛ in. of the BIM, says Green.

The TEC doubles as a living exhibit for visitors to view, from the outside looking in, the workings of the green central plant.

Photo by Sean Airhart/NBBJ

The tricky geofield work also benefited from BIM. The model included well positions, distribution piping, and existing and planned utilities outside of GLY’s contract.

AEI developed the initial plan for potential locations of the geowells during preconstruction. GLY and MacDonald Miller then used the plan to perform initial subsurface test bores and developed the initial BIM to establish potential geowell locations included in the request for proposal for the geothermal subcontractor. Upon the contract award to GeoTility, MacDonald Miller and GeoTility had primary custody of the model with oversight and coordination with GLY.

The model creation was not simple. To develop a dig protocol for each well zone, the team conducted a “potholing” investigation, which consisted of hydro-excavating spots on the perimeter of a zone to establish whether there were active utilities, before connecting the dots to create a dig map.

A significant challenge in planning the geothermal system was finding space for all of the geothermal bores under the crowded field. “The campus is massive in terms of acreage, but getting every last bit of green space would have required excessive amounts of piping across the site,” says AEI’s Oylear.

Bores were spaced 15 ft on center instead of the more common 20 ft. In addition, the depth was typically 550 ft, not the more common 300 ft. Through a design-construction optimization process, the team determined that the quantity of bores could be reduced by about 25% through a combination of increasing bore depth by 10% and the addition of electric hot water boilers to offset about 30% of the peak heating demand.

The electric boilers are a much lower first cost investment compared to an equivalent capacity of geothermal bores and would only be used on the coldest days of the year, says Oylear. That meant only a small decrease in overall campus energy efficiency, he adds.

The optimization exercise highlighted an important aspect of all-electric system design that AEI has carried forward to other jobs. Heat pumps systems are more expensive, particularly when paired with a geothermal source, than non-heat-pump systems. The way to offset this is to size the heat pump component of the system based on the majority of operational hours of the year, and to size a supplemental system to work in combination with the heat pump system during those few hours of the year where the full load is required from the system, Oylear explains.

Geowell drilling took two years. GLY only had permanent custody of half an acre of land. The other well zones had to be “borrowed” from other contractors on campus.

“Instead of getting to drill in the entire field at once, which is preferred, we had to sequence that work in seven separate areas,” each about 40,000 sq ft, says GLY’s Hamm.

The small zones were a consequence of many factors, including existing building demolition and the areas controlled by other general contractors for materials storage, crew tents or new utility installations, which included electrical service, sewers, domestic water, site lighting, data and more, says GLY.

The goal was for these utilities to be installed after the geowells in the 6-ft-deep area between the geowell system and the surface, but in some cases they were below or parallel. That required extra coordination, says Hamm.

Drone Flights

GLY used drone flights to assess and plan for future drilling areas prior to getting those spaces turned over temporarily by the other contractors. “We would assess” visible obstructions, elevations, square footage and slope via the drone, says Hamm.

After excavating 6 ft and leveling a section for drill rig stability, crews would bore a hole, using mud rotary drilling, insert the 1.25-in.-dia looped piping and fill the bore with grout. “The magic was keeping the hole open to insert the loop,” says Stuart Yanow, GeoTility’s president. Collections or groups of geowells were then pipe-manifolded together to a vault and distributed via larger-diameter pipes back to the central plant.

There were workarounds caused by the geology, including abandoning and relocating some bores. “Most of the time, you drill through an obstruction, but it takes longer, wears down drill bits and generally slows overall productivity,” says Yanow. In some cases, “we tried and tried but couldn’t get to the 550-foot depth,” adds Ben Leventer, MacDonald Miller’s senior project manager.

Hamm recalls being in a “panic mode,” when the drill rig hit a boulder it could not drill through, mostly far down. In those cases, which amounted to 25 of the 900 wells, the team drilled to 400 ft and then found other areas to add wells and still meet the design intent. “We revived the system design during construction,” says Leventer. “If we were short 150 feet on a well, we needed to make it up elsewhere,” he adds.

The TEC project also weathered outside forces, including a carpenters’ strike and a teamsters’ strike that interrupted concrete deliveries. Though most of the concrete job, which GLY self-performed, was finished by the time the strike hit, GLY did have to mix 33 cu yd.

COVID-19 and bad weather also had impacts, for a total of 26 lost time days. “We lost 11 days due to weather,” including six to snow, one to extreme heat and four to poor air quality, says Hamm. The remaining lost-time days were due to a delay in the civil permit approval.

In retrospect, OAC’s Green stresses the importance of setting expectations early in the work and of communicating goals regularly. “Hold team members accountable all along the way,” he advises owners, and build the project in the model first. “If you can’t build it perfectly in the model,” which has the same XYZ coordinates as the physical world, “there is a low likelihood you can build it correctly in the real world,” says Green.

A solid BIM execution plan is crucial to success. “Time spent in modeling and clash detection is pennies on the dollar for finding a mistake during construction,” he says. Trust the team but “verify the work in place against the model,” he advises.

Microsoft’s Rovegno also has advice for owners: “Choose very collaborative firms” with track records of working on complex jobs with short timelines.

AEI’s Oylear sums up the job: The TEC “was a career project for everyone involved. We feel this project was ahead of its time [yet] regulations are starting to catch up in a way that we will likely see more projects pursue similar strategies.”

-Janine-Pietz_ENRready.jpg?height=200&t=1737072241&width=200)