New York City's Massive New UV Water Zapper Firing Up

On April 23, contractors began a three-month-long, round-the-clock push to start diverting water from one of the main aqueducts serving New York City into the $1.3-billion Catskill-Delaware Ultraviolet Disinfection Facility. Their challenge is to direct a decades-old, gravity-flow stream through the new plant while slowing it to a rate compatible with UV treatment, all without interrupting the delivery of 85% of the water supply for nine million residents of the city and surrounding areas.

"We can't afford to have anything go wrong. There are a lot of people depending on this," says George Schmitt, accountable manager, Bureau of Engineering, Design & Construction, New York City Dept. of Environmental Protection (NYCDEP).

The facility will treat water from the Cat-Del watershed to meet federal Environmental Protection Agency surface-water treatment requirements, which dictate that all water systems not using filtration install ultraviolet or other approved disinfection methods to inactivate cryptosporidium parasites. The first half of the facility—28 UV units, each with a 60-million-gallon-per-day capacity—is scheduled to start operations on July 2. The entire facility—56 units with a total 2,020 mgd maximum capacity—is to be operational by Aug. 3.

In recent weeks, emphasis at Cat-Del has shifted from big-pipe and heavy-concrete work to disinfecting piping and fine-tuning electrical and instrumentation systems, says Mark Hanson, project director for the Malcolm Pirnie/CH2M Hill joint venture performing $82 million in construction management services. To bring the facility online, "the first thing we will do is test hydraulics, verify it meets the design and make sure we understand how well all the valves work to control the water," Hanson says. "The next step is to test the UV units with water flowing through them."

All piping has been pressure-tested. NYCDEP has tested each UV unit as well as all the operating systems, including electrical and backup power. Now the whole facility will be tested as a unit with water flowing for the first time, says Paul Whitener, principal project manager for CH2M Hill. Because the city will be consuming the water the plant treats during testing, chlorine treatment will be administered, he says.

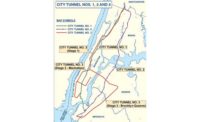

The biggest challenge is testing the facility and maintaining flow while coordinating with the city's many other ongoing water projects. The Delaware and Catskill aqueducts are the main conduits for sending water captured in the Catskill and Delaware watersheds to communities downstream and on to New York City. Initially, only the Delaware Aqueduct flow will be diverted to the UV plant for treatment before being fed back into the two-aqueduct stream, but that source is scheduled for interruptions during the run-in period.

"The [NYCDEP] will be taking the Delaware Aqueduct offline at intervals, for the next month and a half, for other work they are doing in the system," Hanson explains. "That complicates starting up because we need water to do our job."

But those off-line times will provide windows for contractors to install huge steel plates, or "stop shutters," which will force water flow into the facility. "It's not an instantaneous diversion, but a process with a lot of physical work to be done to divert the water," Whitener says. "It's not just like diversity with valves—we've got stop shutters and roller gates. It's not a pump system, so we can't back off if the flow is too great."

Water will be directed from the Delaware Aqueduct into the facility through a 1940s-era shaft that conveys water to grade from aqueducts 400 ft to 1,200 ft deep. "The water comes in from Shaft 19 and is diverted through four 12-ft gates and into the four conduits that transport water through the UV treatment quadrants," says Dinesh Patel, construction manager for the Pirnie/CH2MHill joint venture. "Sixteen energy-dissipating control valves slow down the flow to get enough retention for UV treatment."

The facility will be tested with a 200-mgd flow, which gradually will be increased as each unit is tested. "The [NYCDEP] doesn't need all four quadrants to get all two billion gallons [per day], so they can always do maintenance and still operate 24/7," Patel says.

Cat-Del is designed to add future capacity. "Conveyance to the building now is not more than two billion [gpd], but the building can handle more than that," Schmitt says. Capacity is limited partly by EPA guidelines on UV dosage, which are based on 40 mgd throughput per unit. "We could have increased capacity if we got approval for a higher dose for higher flow rate," Schmitt says. The facility includes stub-outs for a future Catskill Aqueduct tie-in, which is in planning.

The project is subject to a consent-order-driven schedule. The Malcolm Pirnie/CH2M Hill joint venture met all 2011 milestones and is about a month ahead of schedule for the final consent orders.

Ultraviolet disinfection and sterilization of water, like the diesel engine, is century old technology whose Science and Technology was pioneered in Europe and for various reasons, good...

That said a gravity fed water supply is infinity more reliable than one driven by pumps because gravity never fails while pumping system can, and chlorinating water is much more "fail safe" than relying on

continuous electrical power to disinfect and sterilize water although chlorination can fail with destructive microbes while UV never fails.

The age of civil engineering structures is not an absolutely reliable indicator of its condition. Thus decades old and even century old structures may be in fine condition while newer structures may not be.

This is recognized in testing the UV installation on the Delaware portion of the system, the newest portion of the system because of a bad section is the least reliable. Thus it is the ideal portion for carrying out testing.