Texas & Louisiana On the Scene: May 2024

Rendering of the planned replacement of the Kay Bailey Hutchinson Convention Center in Dallas, named for the former Texas governor and set to open in 2028.

Image courtesy of the City of Dallas

As Dallas prepares to issue an RFP for the estimated $3-billion replacement of the Kay Bailey Hutchison Convention Center, Thomas Taylor, a DeSimone Consulting Engineering principal who worked on every addition to its predecessor facility since the 1960s, recently recalled challenges faced on those projects.

Thomas Taylor, Principal, DeSimone Consulting Engineering

“I’ve worked on the convention center since the first renovation started in 1965,” he said, including serving as engineer-of-record on all three upgrades since. The original facility was built in 1957.

At the start of the 1965 renovation, foundation conditions at the site presented numerous challenges, with land around the facility ranging from hard limestone to shallow shale, said Taylor

Crew members were not aware of solid limestone east of the Trinity River, with unstable shale rock to the west reaching 160 ft deep. “At the time it was a surprise. We didn’t know there was shale below the limestone in downtown Dallas,” he told ENR.

To solve the shale issue, crews had to excavate deeper into the shale to lay the foundation.

Another issue was noise and vibration mitigation from freight trains that ran seven days per week under the convention center—then one of the largest column-free exhibition spaces in the U.S.

To deal with the problem, the facility was built on spring isolators, Taylor explained, adding that 350-lb loading was used to support the largest and heaviest exhibits with thousands of tons.

Those issues also posed problems for renovations.

The convention center now is set for demolition, with the larger facility to be built on the current site.

The project’s first phase is expected to start construction at the end of 2024, and complete by 2028. The new building will include 170,000 sq ft of ballroom area, 260,000 sq ft of meeting space and 800,000 sq ft of exhibit space. Plans also include a revival of its surrounding area, with upscale hotels, shopping and parks.

Taylor said he believes the new facility will catapult Dallas into a top convention destination. Last year, the city placed fifth on one industry ranking of top U.S. convention sites.

“I think we could capture the No. 2 spot,” he said, although agreeing the city could not dethrone Las Vegas. The new convention center and its surroundings could help bring an Olympic Games to Dallas, said Taylor, who was instrumental in a center expansion that helped the city mount a bid to host the 2012 Summer Olympics. London was the winning city for the event.

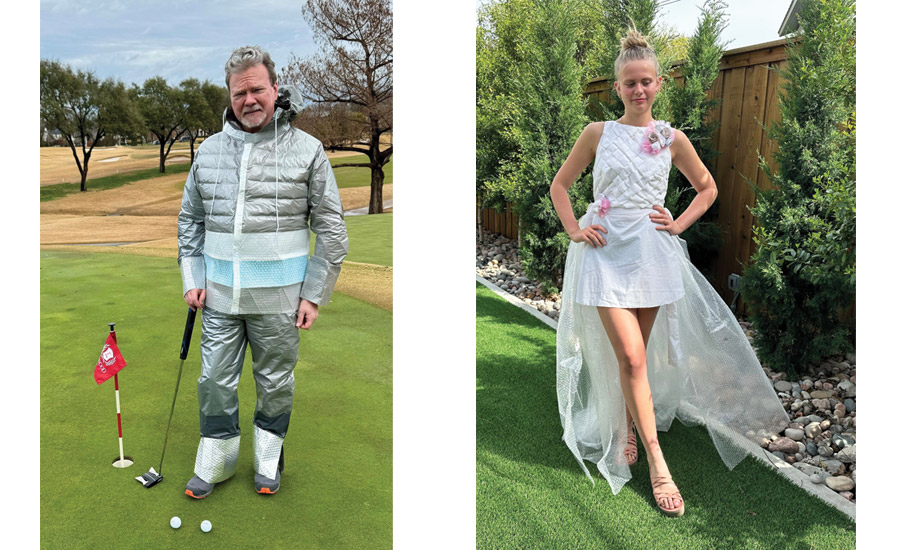

Photos courtesy of HKS

High fashion and construction are not often used in the same sentence, but Texas’ largest design firm, Dallas-based HKS Inc., is changing that. In April, it hosted its annual TRASHION Show at the Galleria Dallas shopping mall, an event that showcases creative waste reduction through reusing, recycling and repurposing of materials, part of the company’s environmental, social and governance (ESG) strategy.

Materials used in this year’s garments, such as those shown above, include packaging, plastic grocery bags, dryer sheets, candy wrappers, chip bags, bottle caps, paper cups, plastic bottles and wine corks, said Caitlin Potter, HKS vice president and TRASHION Show champion. Firm employees were challenged to reimagine their everyday trash into a creation fit for the runway, she said.

The event marks the fourth year of the HKS show, part of ESG in Design, a two-week business focus on how ESG priorities affect architecture and design.

“We introduced the TRASHION Show in 2019 for our firm to participate in these events by showcasing creativity,” Potter explained. HKS also joined in early 2020 the UN Global Compact, an agreement between the international entity and other global organizations to boost worldwide sustainability practices. The TRASHION Show idea developed while Potter attended the Mississippi State University College of Architecture, Art and Design. “We had a very similar design competition where architecture students created high-fashion garments out of trash,” she said.

The theme for the 2024 HKS TRASHION Show focuses on the four main elements—water, air, earth and fire. Garments created must have at least 90% reused or repurposed materials. They now are featured in window displays on Level 1 of the Galleria Dallas mall until June 23.

Enel North America said it has started work on the Ables Springs Solar + Storage project, which includes a 186-MW solar farm and 115-MW battery storage unit in Kaufman County, Texas. The project makes Enel the state’s largest utility-scale energy storage operator, said Stephen Pike, who leads U.S. and Canada clean energy work for the Italy-based developer. The firm has developed 3.8 GW of solar and wind capacity and 1 GW of grid-scale battery storage in Texas, he said.

The Able Springs project, co-developed by Red River Renewable Energy LLC, is set to deliver about 320 gigawatt-hours of power annually in Texas when online at the end of 2024 and create about 200 construction jobs, Pike said. The construction cost was not disclosed. Enel's first state battery project began operation in 2021.

Enel said it is partnering with Texas State Technical College to support scholarships for student training in wind, solar and battery technician programs, and also will contribute funding to local emergency responders and STEM education programs.

The Sundt Foundation, part of contractor Sundt Corp., has awarded $19,600 in grants to four Dallas-Fort Worth area nonprofits. They are Sleep in Heavenly Peace, which provides beds to children in need; Our Daily Bread Inc., to support transportation for program participants; The Welman Project, for school supplies and materials to North Texas teachers; and KADA, to promote hands-on STEM learning experiences for disadvantaged children. Barbara Terry, regional board member, said the nonprofits “are addressing key needs in our community.”