Digging Deeper | Transportation

In Phoenix, Crews Thread Needle With $730M Broadway Curve Revamp

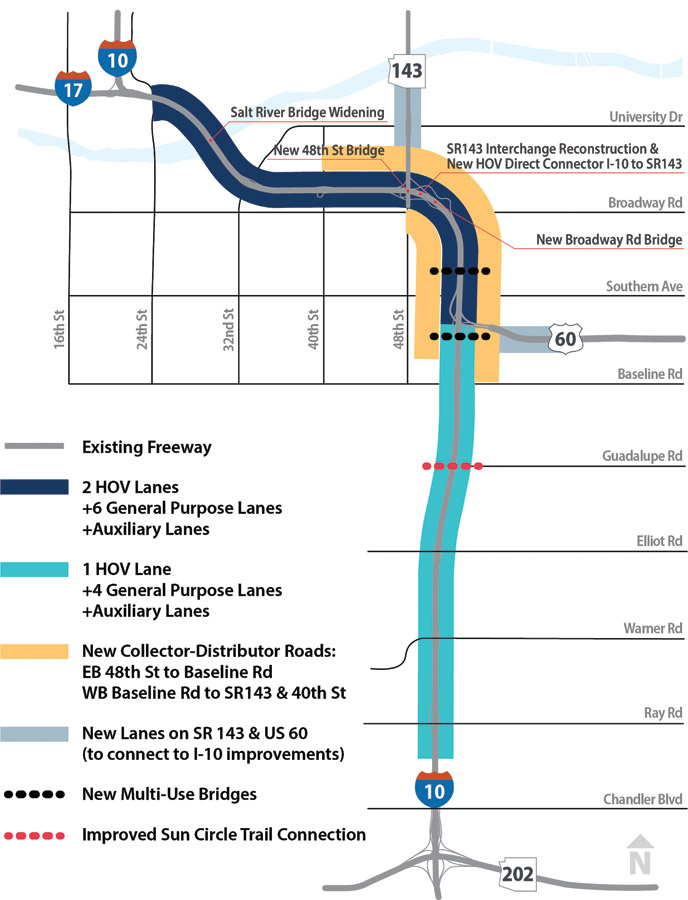

Traffic flow between S.R. 143 (bottom of image) and I-10 will be eased by gently curving ramps, eliminating the extreme curves of the former interchange.

Photo courtesy ADOT

Motorists scrambling to dart across three lanes of traffic when merging onto the freeway. Vehicles slowing to a crawl due to extremely curved exit ramps. Commuters enduring agonizing backups as three freeways converge in a tight footprint. Bicyclists and pedestrians sweating through long detours to traverse freeways.

These are just a few of the many problems the Arizona Dept. of Transportation (ADOT) has long sought to solve with a major do-over of the Interstate 10 Broadway Curve corridor. By constructing or rebuilding 21 bridges, adding lanes and introducing drivers to the concept of collector-distributor roads, ADOT’s largest freeway reconstruction project to date aims to untangle the convoluted interchanges and simplify navigation through one of Arizona’s most heavily traveled corridors.

But the effort hasn’t come without its own brainteasers, including committing to not close any main lanes of traffic during weekdays, complex construction sequencing with ever-shifting traffic alignments and constant engagement with stakeholders, businesses and the public to keep commuters—and the project—on route.

Crews placed the final beams for the 21 bridge structures on the project last month.

Photos courtesy ADOT

Multipronged Partnership

Around eight months remain on the public-private partnership design-build effort that began in July 2021. Of the $729.7-million total construction budget, $616.6 million of that has been allocated to developer Broadway Curve Constructors (BCC), a joint venture of Pulice Construction, FNF Construction and Flatiron Contractors.

While not a traditional P3 in which the builders also hold a maintenance or operations contract for a number of years, the P3/DB model gave BCC more flexibility during the procurement process and also enabled ADOT to negotiate with the best-value winner to incorporate ideas that other teams brought to the table, says Steve Campbell, BCC project manager and senior vice president with Pulice.

The contract includes a $50,000 per day early completion incentive, capped at $3 million, and a $70,000 penalty for each day late, says Marcy McMacken, ADOT spokesperson.

The project was originally identified as a priority by the Maricopa Association of Governments and funded by a voter-approved sales tax in 2004. ADOT performed in-depth studies from 2014-2017, and environmental review wrapped up in early 2020.

ADOT created informational videos and animated visualizations to introduce commuters to the concept of collector-distributor roads.

Schematics courtesy ADOT

*Click the images for greater detail

Design fell to TYLin International, Stanley Consultants and Aztec Engineering, but the concept of the collector-distributor (CD) roads had already been baked in by ADOT by the time the project went out for proposals, says Josiah Roberts, principal project manager with TYLin.

One of the design team’s biggest tasks was to track over 1,500 potential utility conflicts with over 30 different utility companies and coordinate over 70 sets of relocation plans, Roberts adds.

Currently, 300,000 vehicles pass through the scope area on an average weekday, and that’s expected to increase by 25% in the next 15 years. Because U.S. 60 and S.R. 143 both terminate into I-10 within a short distance of each other, “you have a lot of traffic that’s changing lanes and jockeying to get into position to where they need to go,” says McMacken. “The purpose of the CD roads is to separate the mainline traffic that’s just passing through the Broadway Curve area from the traffic that’s trying to get off at U.S. 60 or S.R. 143 or Broadway Road or 40th Street.”

Along with the CD roads, crews will widen and improve an 11-mile stretch of I-10 from Ray Road on the southern edge to just north of the Salt River where I-17 splits off. In some areas, an additional HOV lane and two general purpose lanes will be added (see map above). At its widest, I-10 will contain 26 lanes.

The 21 major structural elements include two new pedestrian/bicycle bridges.

“There are more than 5,000 businesses along this 11-mile corridor that are affected.”

—Nicole Moon, Public Involvement Lead, WSP

But interweaving the structures and CD roads throughout the busy interchanges has been a Herculean sequencing task for BCC. “Our commitment to the job is making sure that we’re maintaining the same number of lanes in each direction at all times, except for when we’ve got a full freeway closure,” says Luke Peterson, BCC construction manager. “So from a phasing standpoint, we’ve probably done four or five major shifts on traffic alignments just to make sure that we’re keeping the same number of lanes.”

For improving and widening the existing roadway, “we have to be able to get to those older work areas while still maintaining the same number of lanes” by splitting traffic around both sides of a construction zone, Peterson says. “The idea of splitting traffic to maintain freeway speeds is new to the Phoenix area.”

For the first major split orchestrated last fall, through-traffic was cleaved into two flows that pass around new ramps being constructed in the middle. Another major split comes later this summer over the Salt River Bridge, which is being widened as part of the project.

With a workforce exceeding 3,000 people, heat mitigation becomes critical during the busy summer months. Some crews, such as those building ramps and bridges, begin work at 2 a.m. or 3 a.m. Grading crews begin their shift at 5 a.m. “Most of the shifts are done by 1-2 p.m. before the sun’s really at its peak,” he says.

“People work behind temporary concrete barriers or they have a crash attenuator truck with them.”

—Steve Campbell, Project Manager, BCC

The contracting team also can schedule up to 25 weekend closures in the Broadway Curve area in each direction, plus a number of nighttime lane restrictions, during which crews and subcontractors work throughout the night.

With so much pass-through traffic, BCC puts a heavy emphasis on jobsite safety. “One of the things that we continue to pound in everybody’s head is: We can control ourselves, but we can’t control the traveling public,” says Pulice’s Campbell. While the posted speed limit is 55, driver speeds frequently exceed that. “People work behind temporary concrete barriers or they have a crash attenuator truck with them. There’s no latitude to say, ‘I’m only going to be out there for 10 minutes.’ There’s a 30-ft clear zone that you have to be behind.”

Crews take advantage of shade below one of two new pedestrian bridges (left). During a weekend closure to demo old overpasses (right), ADOT created the award-winning Ready to Rubble awareness campaign.

Photos courtesy ADOT

Award-winning Outreach

The project enabled ADOT to boost its public engagement to the next level. “It was really important to us during the environmental review phase to invite the public to be part of the project,” says Nicole Moon, public involvement lead for the project’s general engineering consultant WSP USA. “There are more than 5,000 businesses along this 11-mile corridor that are affected. So we had a business forum in 2019 and a freight and logistics forum because we wanted to talk with those people that were going to be most impacted by construction on our project.”

To avoid both the desert high temperatures and busiest traffic times, crews often work nights and early mornings.

Photo courtesy ADOT

One key insight from the outreach revealed that many businesses operate trucks for shipping or other purposes during the night, and giving them at least two weeks advance notice on overnight lane restrictions or weekend closures would greatly ease impacts to their businesses, Moon says.

The BCC team included mobility management firm Iteris in their original proposal as an added value, Campbell says. Iteris uses proprietary software to gather live cell phone data to track and analyze traffic during closures. This helps optimize future closures and assist with traffic management in and around the project, TYLin’s Roberts adds.

Crews widen Salt River Bridge, shown from above and below. During last year’s wet winter, high rainfall upstream required dam releases, which flooded the construction site for bridge pier foundations for several months.

Photos courtesy ADOT

The project also called for ADOT’s first project-specific mobile app, which has been downloaded more than 20,000 times to provide users with up-to-date information. Also a first, ADOT runs a paid advertising campaign via TV ads, social media and billboards “to get project information out to a much larger group of people instead of just those that are along the corridor,” Moon adds.

Also on social media, ADOT’s McMacken has been producing regular behind-the-scenes hardhat tour videos. Moon says the videos are helpful “because we want you to be watching the video on social media and not watching the crews while you’re driving through the project. It’s been a very successful campaign for us.”

In April 2023, a major weekend shutdown occurred to demolish the former 48th Street and Broadway Road bridges. To boost public awareness of the closure, ADOT created the Ready to Rubble: the Ultimate Bridge Takedown event. Stakeholders and media were invited to the site, and visuals were circulated to the public detailing the bridge removal process, McMacken says. The successful effort garnered awards for innovation from the Transportation Research Board, American Association of State Highway and Transportation Officials and Women’s Transportation Seminar.

Later this summer, drivers will get their first taste of the CD roads as traffic gets pushed over to enable work to continue on the median areas. To prepare, ADOT initiated a Find Your Lane campaign to assist drivers with adjusting to the new transportation paradigm.

Peterson says he looks forward to the shift, which will enable the final steps in the long construction journey: “It will let us do the final diamond grinding and asphalt surfacing, put final striping down, do the overhead sign work and final painting to really put the shine on the job.”