A 1972 ENR cover story said of Wiss Janney Elstner Associates in Northbrook, Ill., “It exists largely by looking for trouble, both before and after the fact of structural distress and failure.”

More than 50 years later, WJE and the field of forensic engineering are no longer seen as the novelties they were at the time. Decades worth of research produced since then has informed the design and construction of thousands of buildings, roads, bridges and other projects. Studies and tests performed by forensic engineering firms have made designs more efficient, turned unknowns into knowns and made building with newer technologies a far less risky proposition. As other firms joined the field, the marketplace for forensic engineering and investigative services has grown, reaching $5.1 billion in 2023, according to Global Market Insights. WJE ranked 122 in ENR’s 2024 Top 500 Design Firms, with $213.7 million in revenue.

“[WJE founder] Jack Janney used to say that one test is worth 1,000 expert opinions,” quotes William Nugent, president and CEO of WJE. “We believe that. No offense to experts intended, we consider ourselves experts, but when you can set something up and prove it physically, you’re ahead of the game. We can solve the problems we believe that nobody else can solve because we have that laboratory.”

The laboratory Nugent is referring to is the Janney Technical Center, a 70,000-sq-ft research laboratory in Northbrook, Ill., but the firm also has labs in Cleveland and Austin, Texas. The array of services the labs offer include structural testing and evaluation, materials testing and evaluation, facade testing, petrographic and microscopic evaluation, thermal analysis, chemical testing, metallurgical testing, corrosion analysis, fatigue and fracture analysis, nondestructive testing and evaluation, instrumentation and load testing, and code compliance testing.

One of the most important investigations the firm did was the 1981 collapse of two skywalks in the lobby of the Hyatt Regency Hotel in Kansas City, Mo. Two of the three 145-ft-long skywalks collapsed onto a dance floor below, killing 114 people and injuring 216. The incident remains the deadliest non-deliberate structural failure in U.S. history, according to the late structural engineer and investigator Henry Petroski in his 1985 book "To Engineer is Human."

In 1996 the NTSB called in WJE to investigate and reassemble pieces of TWA Flight 800 because of its past investigations of bridge collapses.

Photos courtesy of Wiss Janney Elstner Associates

Within hours of the accident, WJE assembled a team and arrived at the site. WJE’s president at the time, John Hanson, advised Gary Klein—now WJE executive vice president and senior principal—to get a team on the site and document everything. Initial visual inspections of the fallen walkways revealed severe distortion of the box beams, particularly where they connected to the hanger rods, which had failed.

To get a better understanding of the contributing conditions, WJE performed laboratory tests on replicas of the connections between the hanger rods and box beams. The results lined up with what WJE had found in its field survey. The investigation revealed that a last-minute construction change in the hanger rod arrangement had overburdened the fourth-floor walkway with a load transfer twice its designed capacity. Forced to support its own weight and the weight of the second-floor walkway beneath it, the middle fourth-floor structural box beam connection had failed.

WJE engineers were called in to inspect the exterior steel of the St. Louis Gateway Arch to determine the cause of discoloration and rusting.

Photo courtesy of Wiss Janney Elstner Associates

The final report issued by the National Bureau of Standards (now known as the National Institute of Standards and Technology) cited a structural overload due to design flaws that resulted in the walkways only having a minimal capacity to resist their own weight. The collapse and investigation had a tremendous impact on steel construction in the U.S. as well as on the expected responsibilities of structural engineers and steel fabricators.

“There are changes [in construction technology] that present new problems, and we like to think we have been at the forefront of [investigating] those,” says Klein. “If you look back in the early eighties, there were a lot of problems. The Hartford Civic Center Arena, the Kansas City Hyatt walkways, parking garage failures and really major collapses. I like to think that the industry has learned from those mistakes, and that we’ve maybe even contributed to a better understanding of how structures fail to prevent them from happening again.”

Going Beyond Buildings

As construction methods and materials have changed, methods of investigation have had to as well. The scope of WJE’s investigations changed dramatically in July 1996 when the National Transportation Safety Board asked the firm to investigate the crash of TWA Flight 800 after the plane exploded roughly 12 minutes after takeoff from JFK International Airport in New York City, killing all 230 people onboard.

“NTSB knew us because we had investigated several bridge collapses under their jurisdiction; they also have jurisdiction over transportation disasters,” Nugent explains.

The NTSB asked WJE to reassemble a 100-ft section of recovered pieces of the 300-ft plane’s fuselage. The main fuel tank, keel beam, cargo areas and pressure deck all had to be put back together in a manner that permitted viewing of the reassembled surfaces and installation of the passenger seating in the reconstruction. The reassembled aircraft structure needed to be rolled out of its hangar at a Grumman facility in Long Island after completion using a system WJE designed. And NTSB said the reconstruction had to be done in just over four months.

“We got the 100-ft section back together and it was a key piece for NTSB in order to figure out what happened. You could clearly see there had been an explosion in the center fuel tank just by the shape of the pieces when we got them back together,” Nugent recalls.

When Richard Elstner, Jack Janney and John Wiss were featured in ENR in 1972, their approach was novel.

Cover from ENR Archives

The ensuing NTSB report said the probable cause of the accident was the explosion of flammable fuel vapors from the center fuel tank. Although it couldn’t be determined with certainty, the likely ignition source was a short circuit.

After the investigation was completed, NTSB moved the reconstructed section of TWA 800 to an NTSB facility in Ashburn, Va., custom-built as a training facility for accident investigators. The facility was decommissioned in 2021 after NTSB switched to computer models for its future investigations.

“As soon as the legal stuff is behind us on these investigations, we share everything we learned and make it public, because it makes the profession better,” Nugent said. “It’s one of the reasons why we have less of the real catastrophic things happening today. Part of our mission is to solve problems, but it’s also to share what we learn with each other and with the world.”

WJE maintains an online database of tens of thousands of investigation reports searchable by keyword to inform its future efforts.

A difficult-access team member ascends a cable support for a roof. At right, engineers Ann Harrer and Brian Chen inspect a ceiling in the Big Dig.

Photos courtesy of Wiss Janney Elstner Associates

Existing Conditions

While the investigations into structural failures get more attention, investigations of existing conditions and recommendations for dealing with problems before failures occur make up a significant portion of WJE’s work today.

Discoloration, streaking and surface irregularities on the stainless steel exterior of St. Louis’ iconic Gateway Arch were a cause for concern for the National Park Service in the early 2000s. It sought an assessment of the structure to determine the source of the apparent corrosion and staining of the steel, and wanted repair recommendations based on the landmark’s historical context.

From 2005-15, WJE investigated and documented the history and conditions of the Gateway Arch. Visible stains and blemishes on the stainless steel skin and the condition of the interior of the structure were examined, with samples analyzed in WJE’s lab. A thermal and relative humidity monitoring system was installed to better understand the potential for microclimates and possible causes of deterioration inside the arch. A historic structure report was completed to serve as a planning tool for the long-term preservation of the monument.

During the final phase of the investigation, areas of the stainless steel skin that appeared discolored from ground level were examined up close for the first time using industry-standard rope access techniques. WJE architects, access experts, conservators and engineers worked to document and investigate the causes of the discoloration of the skin and conduct cleaning trials to mitigate them.

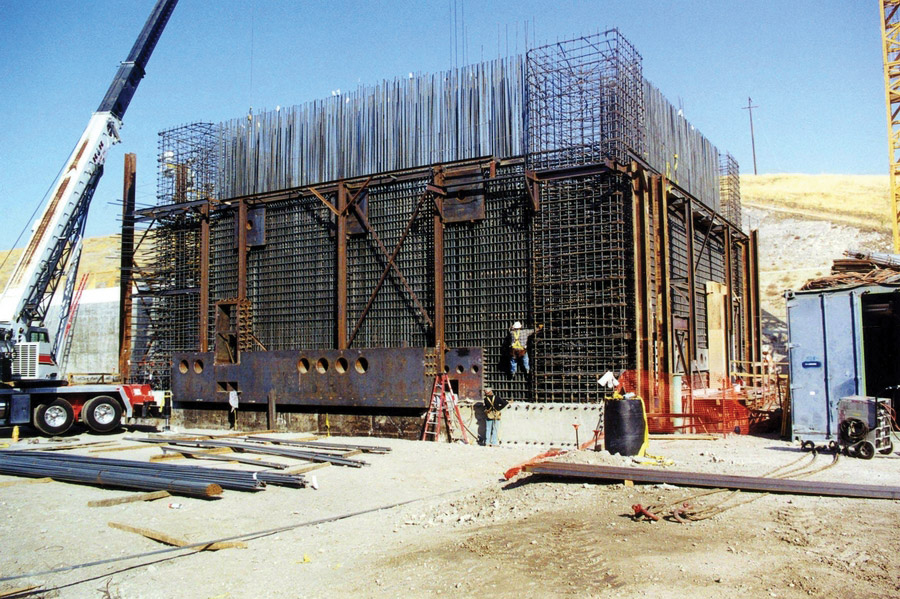

Site 300 at Lawrence Livermore National Lab (below left) has instrumentation sensors to measure blasts installed by WJE. At right, a WJE engineer examines concrete debris at the Surfside condo collapse site in Florida.

Photos courtesy of Wiss Janney Elstner Associates

The team was able to identify, assess and develop treatment recommendations for the long-term preservation of the Gateway Arch. WJE’s knowledge of materials conservation, engineering and extensive experience in preservation techniques contributed to meet the National Park Service’s goal of developing a long-term preservation plan for the Eero Saarinen-designed landmark. The report found the discoloration was due to blemishes and markings from the Arch’s initial construction, built-up pollution, graffiti and stains from superficial corrosion, and that it was structurally sound and in overall serviceable condition, considering its age.

“We’ve learned a lot over the years and have developed the laboratory skills and field testing skills to go along with that problem-solving practice,” Klein says.

As the needs for assessments of conditions and investigations have changed, so have WJE’s services. A unique situation was Boston’s $24.3-billion Big Dig project. During its construction between 1991 and 2007, the Central Artery/Third Tunnel project rerouted Interstate 93 through the heart of Boston into a 3.5-mile tunnel underneath the city and extended Interstate 90 east to Logan Airport underneath Boston Harbor. The most expensive highway project in U.S. history, it was already plagued by overruns, leaks and design flaws when on July 10, 2006, a concrete ceiling panel and debris fell in Boston’s Fort Point Channel Tunnel. The panel fell on a car traveling on the two-lane ramp connecting northbound Interstate 93 to eastbound Interstate 90, killing a passenger and injuring the driver. Then Massachusetts Gov. Mitt Romney ordered a safety review of the entire Metropolitan Highway System and brought in WJE.

“It was more to restore public confidence and ferret out where there might be weaknesses that needed correction as quickly as possible. That was the challenge. He wanted the report on his desk in 90 days,” Klein says.

WJE’s interdisciplinary team provided an evaluation of the design and construction of the Big Dig tunnels and facilities. The WJE team, more experienced in structural evaluations, worked with experts in electrical, mechanical and life safety systems, examining over 66 lane miles of roadway, tunnels and structures, with minimal disruption to operations and within the project’s delivery schedule. WJE documented deficiencies and recommended priorities for action—from immediate repairs to continued service with monitoring.

Phase one of the investigation consisted of a review of the Big Dig tunnel structures and finishes, including precast and cast-in-place concrete and steel-framed tunnel structures, precast concrete and metal ceiling panels, tile wall finishes, epoxied anchors and appurtenances. WJE’s work included extensive field investigations consisting of visual inspections and nondestructive testing, with subsequent finite element analyses of critical components.

WJE teams assess the Chicago Skyway Bridge (above left) and a 1,500-ft-long deck truss-arch of the Perrine Bridge over the Snake River in Idaho.

Photos courtesy of Wiss Janney Elstner Associates

Complicating matters was the fact that NTSB’s own investigation into the fatal accident was happening at the same time as WJE’s full, system-level review. “Their investigation was focused on one connection. Our investigation was the entire project plus some older tunnels that were part of what they call the MHS system,” Klein explains.

In the second phase, WJE’s scope was expanded to include evaluations of additional structures and roadways adjacent to the CA/T system. Specific repair recommendations and designs to address deficiencies recorded in the first phase’s investigations were provided.

“We accommodated them and delivered the report in time, recognizing that certain things would be scheduled for follow-up investigations that weren’t of an urgent nature. And we actually continued work on the project for most of 2007,” Klein says.

The team of Bechtel and Parsons Brinckerhoff serving as contractor and design consultant for the project agreed to a nearly $408-million settlement in 2008 to resolve all related liabilities.

As Nugent said, passing along the engineering knowledge, experience and findings of the firm’s teams to the next generation of 300-plus employee owners has always been a company value at WJE. The youngest engineer on the team in 1981 who rushed to Kansas City to investigate the collapse of the Hyatt walkways had only been at the firm for two years at the time. His name is Gary Klein.