2024 Southwest Best Projects

Teamwork, Safety Keeps Phoenix Transit Line Project on Track

Northwest Phase II Extension Light Rail Transit project selected as ENR Southwest's 2024 Project of the Year

The 1.6-mile Northwest Phase II Extension brings the transit system to the West Valley for the first time and is expected to add about 1,400 new daily riders.

Photo courtesy McCarthy Building Cos.

Northwest Phase II Extension Light Rail Transit

Phoenix

PROJECT OF THE YEAR; BEST PROJECT, AIRPORT/TRANSIT and EXCELLENCE IN SAFETY

KEY PLAYERS

Submitted by: Kiewit-McCarthy, a Joint Venture (KMJV)

Owner: Valley Metro Rail

Lead Design Firm; Civil/Structural Engineer: Jacobs

General Contractor: Kiewit-McCarthy, a Joint Venture

MEP Engineer: Sun Engineering (Operator Building); Jacobs (Other Electrical)

Parking Garage Design Firm: Walker Consultants

Landscape Architect: Dig Studio

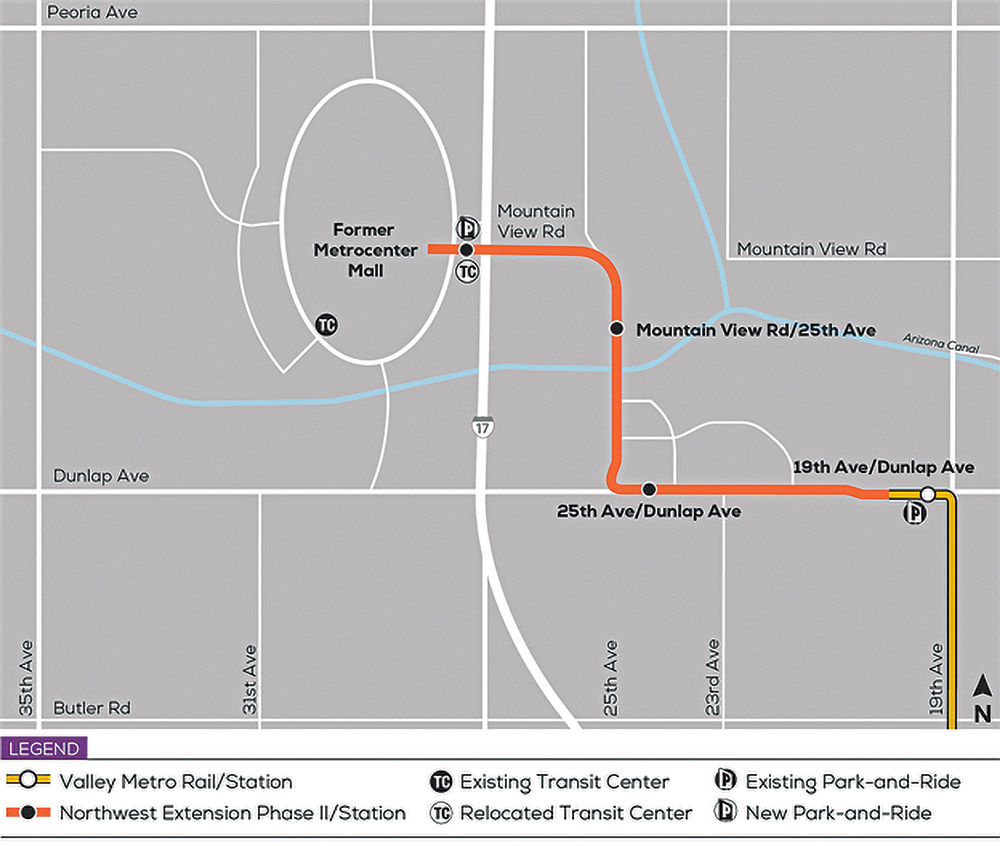

The new line (map, above) connects to an existing station at 19th Avenue and Dunlap and then extends north and west to the former Metrocenter Mall site, which is under redevelopment.

Map courtesy Valley Metro

*Click on the map for greater detail

While clocking in at 1.6 miles in length, Valley Metro’s newest section of its Phoenix light rail system packs in many firsts for the area within its tight footprint. The Northwest Phase II Extension provides the network’s first elevated light rail track and station, the first rail-only bridge over Interstate 17 and the first multimodal transit center and parking structure for the system.

Additionally, it’s the first time light rail has been connected to the West Valley. And the project features the first utilization of steel fiber concrete on the guideway. While breaking all of this new ground, the team also faced a utility relocation backlog that threatened to delay the project. Instead, the team brought the project into the station early, with an impressive $40 million in savings and a nearly spotless safety record.

The extension features the first rail-only bridge over Interstate 17, a heavily used commuter corridor.

Photo courtesy McCarthy Building Cos.

Designed by Jacobs, the extension runs west on Dunlap Avenue starting at 19th Avenue, then turns north on 25th Avenue and runs across I-17 at Mountain View Road, ending on the west side of the freeway near the former Metrocenter Mall. In addition to the elevated station on the west side of I-17, crews built two new at-grade stations and two other bridges. The four-story transit center is served by five bus routes and contains a 90,830-sq-ft parking garage with 252 stalls for Valley Metro’s Park and Ride Program.

Valley Metro awarded a construction manager at-risk contract to the joint venture of Kiewit-McCarthy (KMJV) early on when the project was still at about 15% design, which enabled the team to perform extensive value engineering to keep the project moving forward under its limited funding.

During a cost savings and risk workshop, KMJV, the city of Phoenix, Valley Metro, Jacobs and others “locked ourselves in a conference room for three days and brainstormed what scope of work was unnecessary and how do we meet the functionality of the project at the lowest cost,” says Nick Wiatrowski, area manager at Kiewit. Through the strategy, elements such as the lighting package were simplified, and in the end 141 cost saving ideas were agreed upon, carving out $61 million from the initial forecast.

Photo courtesy McCarthy Building Cos.

The final construction cost came in at $273.8 million, around $40 million under budget.

The project received funding from regional transportation pools and ballot measures, plus $158 million from the Capital Investment Grant program through the Federal Transit Administration.

At the ribbon-cutting ceremony in January, FTA administrator Nuria Fernandez said: “I am proud to be back in Phoenix, less than three years after signing the grant that funded this important extension that will make such a difference in the lives of people in this region. This was the first project funded by FTA under President Biden’s Bipartisan Infrastructure Law, and the city and Valley Metro have done incredible work ... delivering the project earlier than expected.”

Crews from the contracting team were empowered to identify safety concerns and come up with appropriate solutions. This included the power to stop work at any time if unsafe practices were observed.

Photo courtesy McCarthy Building Cos.

Utility Backlog

The project broke ground in 2020 right as the industry was dealing with the peak of the pandemic. But the impacts of COVID-19 manifested in unexpected ways on the project.

“For Phoenix, COVID really created an enormous construction boom, and there was just an insurmountable amount of construction that was occurring,” says Wiatrowski. “It put a ton of stress on the local utility companies right at about the same time where we needed them on our project relocating utilities so that we could begin our work.” A seven-month project delay loomed due to the labor and resource shortages at the third-party utilities. “That wasn’t acceptable for anybody,” he adds.

“I would love to do a project again with the same team and the same vibe and recreate that magic.”

—Chris Jacobson, SVP Operations, McCarthy Building Cos.

To claw back lost time, the team held another round of brainstorming and implemented strategies such as double shifts on critical items, resequencing work to reduce the number of traffic control phases and enlisting extra bench strength from the two companies.

A decade ago, KMJV worked together on another Best Projects winner, the PHX Sky Train, which judges lauded for combining the strengths of Kiewit’s infrastructure experience and McCarthy’s vertical construction acumen. Chris Jacobson, senior vice president of operations for McCarthy, says the “secret sauce” of the light rail project was “our expertise played in the exact same way with Kiewit focused on the horizontal and McCarthy focused on the [elevated] station, but our teams were integrated.”

To ensure the greatest level of partnering, KMJV says both firms were equally involved in “planning and decision-making, even allocating internal resources to one another for highest project outcomes.”

Due to the shared labor, equipment and self-performance expertise, KMJV says it was able to self-perform extensive parts of the job, including 21,000 linear ft of underground utility relocations, earthwork, bridge widenings, the I-17 overpass bridge, MSE walls, concrete for the Metro Center Station and all of the double-track installation.

Wiatrowski says one of the most significant ideas from the value engineering workshop was to substitute steel fiber in the concrete mix for the embedded guideway, direct fixated track and bridge elements in lieu of extensive reinforcing bars. The team developed the mix with Arizona State University, which validated the methodology for safety and strength.

This method not only reduced the amount of steel, but its stronger load-bearing capacity reduced the thickness of concrete from 14 in. to around 12 in., Wiatrowski adds. In all, the method reduced embodied carbon and cut track construction time in half by 121 days, saving millions of dollars. Concrete tolerances for the 180-ft-long elevated platform left “microscopic room for error,” says the team, requiring 550 pre-pour measurements to ensure accuracy.

The extension featured the light rail system’s first elevated station, located at the terminus of a new multimodal transit center, also built as part of the project.

Photo courtesy McCarthy Building Cos.

Leadership in Safety

The safety experts tasked with selecting the winner of ENR’s special safety award praised the depth and dedication of KMJV’s program.

“Looking at the different structures that we had—several bridges working in and around traffic, lots of heavy equipment—there’s a pitfall around every corner,” says Jacobson. “Our team did an awesome job of communicating all the way down to the craft level.” In combining their safety cultures, both contractors compared their internal practices to select whichever one was more rigorous. This resulted in a high-intensity safety program for all team members to adopt within a culture of collective decision-making, says KMJV.

The team also used underground mapping software that merged as-builts with designed utility relocations to visualize all utilities via GPS, made accessible to all workers on their mobile devices to prevent dangerous utility strikes. With construction continuing over three summer seasons, heat mitigation was also a primary concern, Jacobson says.

Artwork is incorporated throughout the project’s ground level and elevated stations and along the alignment, reflecting the community the transit line serves.

Out of 786,819 worker hours, the team’s OSHA recordable incident rate and lost-time rate both came in at 0.25, due to “a single subcontractor recordable incident on the project involving an employee coming into contact with a piece of the corner of the garage formwork system, resulting in a laceration,” according to the entry form. The end result, though, was a safer site when “the team implemented a policy of covering these potential contact hazards by means such as tennis balls, foam and other cushioning materials.”

Adrian Ruiz, director, safety and security for Valley Metro, says that the team’s “safety efforts protected not only the workers performing the work but the very active and vibrant retail and residential area surrounding the build site.” In addition, the design of the “bridge span and elevated station incorporated safety features and design components intended to reduce risk and mitigate hazards for the public,” he adds.

Community engagement was key throughout, from mitigating impacts to businesses during construction to the design of the project. Multiple art elements are featured along the extension, created by seven artists reflecting the character and history of the community.

“The test of a really good JV is if you want to work together again, and I think Nick [Wiatrowski] and I text each other about every week, figuring out what can be our next one,” says Jacobson. “I would love to do a project again with the same team and the same vibe and recreate that magic.”