Only Some Assembly Required: A Kit-of-Parts Approach to Construction

November 20, 2024

Only Some Assembly Required: A Kit-of-Parts Approach to Construction

November 20, 2024Image by Scott Hilling/ENR, photos and 3D models courtesy of WSP

In 2003, Stephen Kieran and James Timberlake wrote Refabricating Architecture, a book that argued the time had come to reevaluate and update basic design and construction methods that have constrained the industry and kept it closer to agriculture in terms of efficiency rather than manufacturing industries such as automotive production and shipbuilding.

The principals of the eponymous Philadelphia-based architecture firm KieranTimberlake further argued that process engineering allowed automotive, shipbuilding and aerospace industries to work better and faster than previous cost and time constraints had allowed and actually redefined their scopes of work—enabling improved quality and scope that transcended traditional limits of those cost-time resources.

Parametric building information modeling was touted as a catalyst for the transition to industrialized construction, as it was for auto manufacturing. But the last two decades have seen only moderate change in construction processes, as change orders and requests for information have become enshrined in cloud-based project management platforms and BIM authoring software.

While manufacturing tolerances are generally tighter and more precise due to computer-controlled machinery and processes in fabrication shops and factories, construction tolerances have stubbornly remained wider and more varied to accommodate variability of on-site conditions. In short, 3D design has not yet caused a widespread shift to tighter tolerances or enabled higher cost certainty from offsite fabrication, outside of assemblies produced by electrical and mechanical contractors.

There are bright spots, however. Design firm WSP and contractor Mace Group are pursuing a new approach that may mark a shift in the quest to industrialize construction processes.

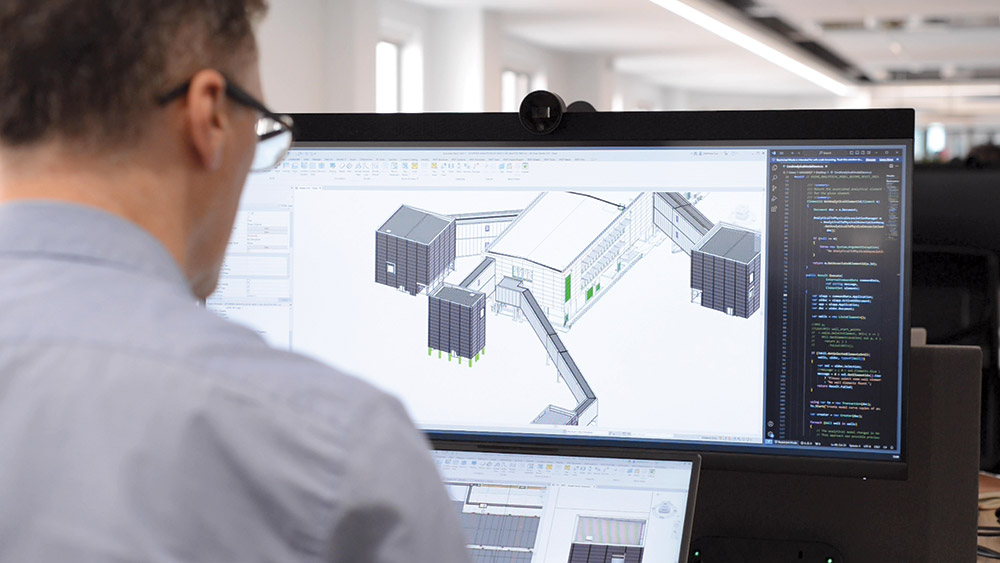

WSP’s plans for nodes at Manchester Airport began as a 3D Revit model.

Photo courtesy of WSP

Rethinking Assembly

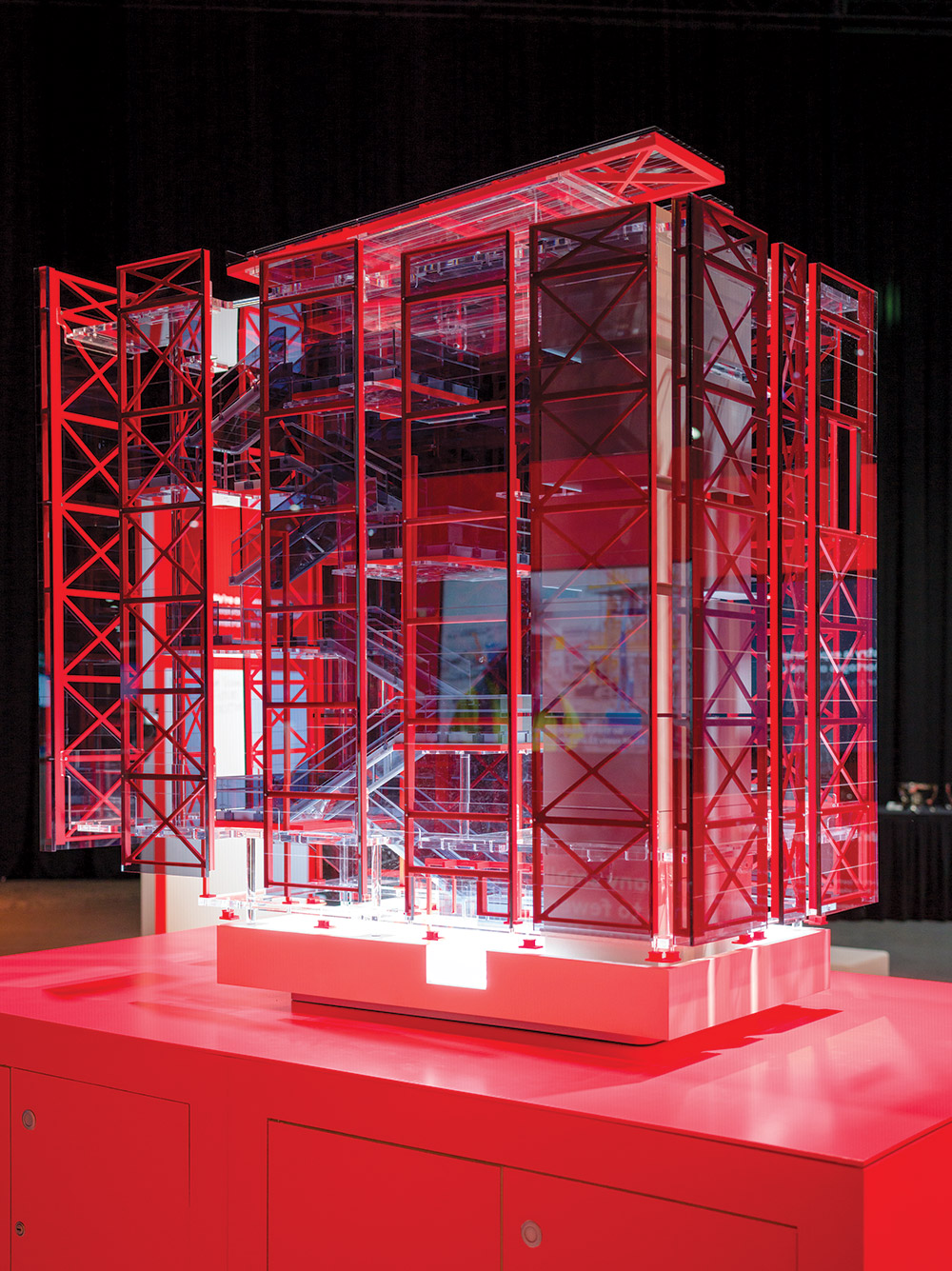

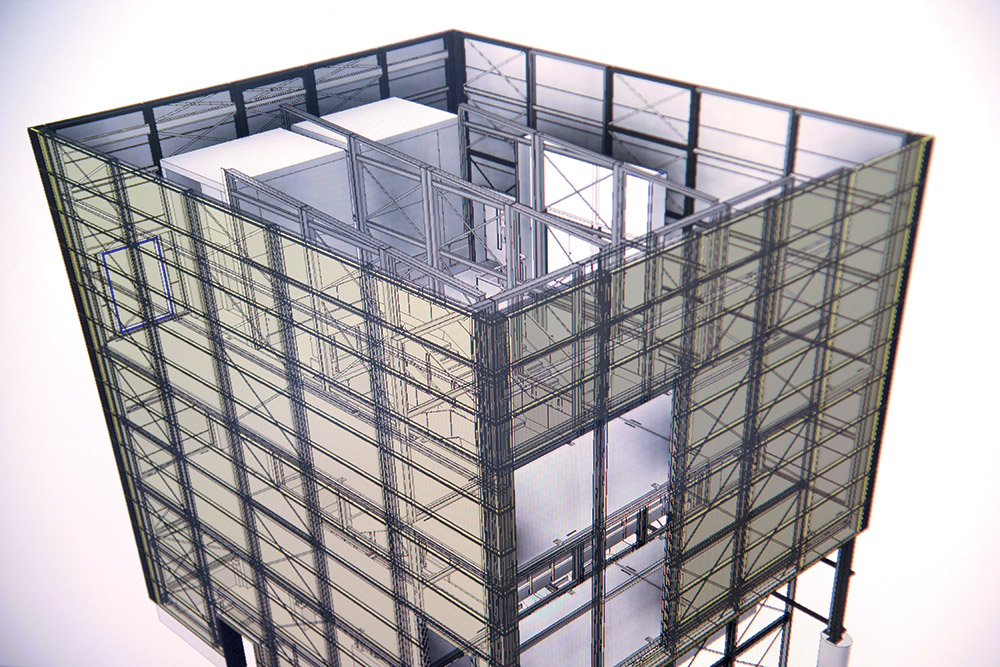

WSP’s plans for Manchester Airport nodes began as a 3D Revit model, with a kit of just 67 parts, first shown in a scale model at Autodesk University.

3d model courtesy of WSP

WSP has developed a kit-of-parts approach as a program-level design management process that combines customized offsite manufacturing and a design for manufacturing and assembly (DfMA) workflow. Autodesk is partnering with the firm on the initiative, with Az Jasat, its senior manager for industrialized construction, assisting to implement the technology. The process lets design teams balance the use of different construction methods, breaking down building designs into larger components that can be manufactured offsite at more precise tolerances before being transported to the site for rapid assembly.

By tracking these components, WSP can scale up from a per-project level and set program-level policies that align to a client’s specific goals. One current WSP client is Manchester Airport in Manchester, Engand. The third-largest U.K. airport is adding a concourse with 12 gates that will enable two of the world’s biggest passenger plane, the Airbus A380, to pass side by side as they move around Terminal 2. The new concourse is the largest part of a $1.65-billion expansion.

The kit-of-parts approach promoted by WSP and project construction manager, Mace, involves installing 150 precast concrete pilings for foundations to support the concourse and a number of steel structures called nodes, which allow different-sized planes to connect to it via air bridges. Each node is comprised of a stairway and elevator core building that allow passengers to change levels between the plane and the gate via a fixed link to the terminal.

Traditionally, nodes would be constructed in the field from thousands of components and transported individually to site. The kit-of-parts approach has reduced the number of parts to just 67, which can all be transported to the site via flatbed trucks.

“You’ve really got to design the details to suit the [construction] sequencing,” says Dale Sinclair, head of digital innovation at WSP. “That’s probably been our main learning point, how to get much slicker at sequencing and the whole lifting [via crane] piece of the installation.”

WSP’s plan for nodes at UK-based Manchester Airport began as a 3D Revit model, with a kit of just 67 parts, was first shown in a scale model at Autodesk University, with detailed drawings then develoed for onsite construction.

3D model courtesy of WSP

In collaboration with Mace, WSP invented a bracket to connect the concrete substructure interfaces to the rest of the node’s core and facade, says Sinclair. That key first step allowed the construction team to take advantage of the much tighter manufacturing tolerances and broader economies of scale that come with reducing the node to so few components.

“The brackets all get ‘lasered in,’” he adds, referencing their placement with laser positioning systems. “The point is that you’ve got a relatively small thing that you can position with the laser before you bring in the really big things. [It lets you make] sure that the site is essentially ready for the tolerances of the bigger things.”

Sinclair’s team at WSP had gotten used to working this way and brought Mace in early in the design process. Other engineers also joined the team as the project scope grew, but getting them used to detailing connections, designing temporary falsework and other project requirements took some educating. WSP also worked closely with the project’s specialty steel engineer, Pro Steel, to ensure nodes came together as planned. The firm is currently working on a program for the U.K. Environment Agency to deliver environmental monitoring stations across the countryside that also will be built using the kit-of-parts approach.

Each airport node was assembled by first completing the stairs and elevator core to provide stiffness. Steel struts and cladding were then connected to these core components.

Photos courtesy of WSP and Mace

It All Fits Together

Before working with WSP on the Manchester Airport nodes project, Mace had already used volumetric and modular techniques to deliver a bridge over an airport taxiway, as well as a new air traffic control tower at Heathrow Airport in London. In those cases, the contractor used strand jacks to slide in bridge sections and an onsite manufacturing facility to fabricate parts of the tower. These approaches allowed the airports to remain in operation during construction, with fewer disruptions to normal activities.

“Dale and I looked at this from that start, and we, at Mace, invested a significant amount of research and development to have the intellectual property, but we needed Dale’s expertise to turn that into an Autodesk model,” says company director Matt Randall.

Using the WSP kit-of-parts approach, Mace was able to reduce its crane demands to six lifts a day and the project schedule to a three-week build time. “If you compare that to a traditional build, that’s 110 days," he says, "if you’re closing a stand for 110 days, [that equates to a $100,000-per-day cost saving] and you can do the [same work] in around 12 days, so suddenly it makes a lot of sense.”

Mace estimates that the kit-of-parts approach—along with a temporary entrance that can bypass the traffic in and around the airport due to reduced volume of deliveries—has shortened the project schedule by 83,000 worker-hours and saved about 125 tons of carbon dioxide emissions compared to a more traditional delivery schedule and sequencing.

The parts for each node are split up into spine walls, corridors, roof cassettes, stairs, stair landings, trestles and fixed-link bridges. The diversified supply chain of where these items are fabricated is itself a virtual tour of the U.K., Randall notes.

“You’ve got some in Wales, some in Manchester, some in London and these are where the build is being done, miles away from the airport,” he explains. “But everybody is building standardized sub assemblies, and by diversifying the supply chain, you can really increase your productivity.”

The finish and paint shops for the sub assemblies are also in the U.K., and can share execution loads if production bottlenecks become an issue.

As in all construction projects, there were some unknown factors. Randall says Mace is looking to improve foundation work. The contractor created footings to get the site to a fixed grade level so all sub assemblies can work off the same reference altitude, but that took time and effort. “The groundwork has taken such a long time to get these bases into alignment,” he says. “That’s something we’ve looked at improving to simplify the foundations.”

Six workers on average were used to construct four completed nodes at Manchester Airport, with the final group of four nodes on track to be built by January.

Photos courtesy of WSP and Mace

From Design to Real Steel

Pro Steel is managing the steel-to-steel connection design, steelwork manufacturing, intumescent fire-rated paint system application, off-site steelwork preassembly and cladding and site installation of all structural steelwork for Manchester Airport’s fixed-link bridges and node buildings.

“We’ve built four of the eight nodes so far, and every single one is getting quicker,” says Steve Richardson, firm project manager. “The target for a single node is basically three weeks, and we’re starting to knock on the door of that. The target for a double node is six weeks and we're very much expecting that for the next one we put up, and that’s a fully clad node.”

Interior finish building trades move in and fit the nodes out after installation, but work on them is more or less finished after a three- or six-week construction schedule. Richardson says node projects each have a six-person crew on average. Pro Steel briefs workers using the 3D models to show context, orientation and constructability issues before they start "because it’s much easier to look at a 3D image,” he says.

One hiccup from node design to construction was having to change some connections designed in the model for constructability.

A typical 15-meter-tall double node has five panels on each side, plus a corner panel, Richardson says. Each panel is about 3-m wide and had slotted holes on the vertical faces where they connect to each other, "which was largely completely pointless because they share a foundation," he says. "Yet, on other elements, where you’ve got three separate large components being joined together … there were no slotted holes." In looking at the design, Richardson says he asked WSP to alter it to provide the holes in these particular brackets.

WSP’s Sinclair adds that his team learned a lot about construction sequencing for crane picks and have since incorporated their lift strategies into the design for the U.K. Environmental Agency stations.

The 3D model of Exchange’s framing also acts as a roadmap to its finished installation.

Photo and image courtesy LIFTbuild

DfMA in the USA

A U.S.-based project that used a similar kit-of-parts approach is Exchange condominium tower in Detroit. Assembled by LIFTbuild, a subsidiary of Barton Malow, the project was delivered via a series of strand jacks and a proprietary “tray” to lift and bolt floor slabs into place after building them on the ground to reduce safety risks and accommodate a tight site with no laydown room. LIFTbuild used supply chain and DfMA techniques similar to the ones WSP, Mace and Pro Steel have used on the Manchester Airport nodes.

“A lot of what we did was taking advantage of assembling things at grade,” says Joe Benvenuto, LIFTbuild chief operating officer. “Some of [that] came from the warehouse facility that we had built and rented for staging and pre-fabrication. The roof is a good example." he notes. "All of that membrane went on, all the rooftop equipment [installation work] is happening on site but before it is lifted into place. All of the penthouse roofs were assembled, membrane put on and all done at grade.”

Another prefabricated component was framing. LIFTbuild worked with Exchange architect Ghafari to model wall framing down to the level of each screw and then roll-forming all studs.

Benvenuto said getting all project team members comfortable with the idea of a DfMA workflow is the most important part of gaining real efficiency savings from the process.

Prefabricated exterior panels were built in a LIFTbuild offsite facility and delivered ready to install to the Exchange condo project site in Detroit.

Photos courtesy LIFTbuild

“We’ll take the program of the building and the documents, with this usually happening in the schematic design phase, so we have an opportunity to change design if needed to support a prefabrication effort,” explains Benvenuto, adding that waiting until the design is done to make these decisions could require changes to accommodate prefabrication goals. "I think that [when the] schematic is just getting into design development-level documents is the right time to do it,” he says.

Benvenuto says laying out a strategy and going through a workshop with all subcontractors to identify opportunities to perform work earlier in the sequence—such as roof membranes and framing—helped enormously on Exchange, which was itself a pilot project for the LIFTbuild system.

“We kind of put together action plans where we would sit down with an architect and address prefabrication strategy and with the engineer,” he adds. “If there were no issues with designing things the way we normally would, if this was solely a means and methods [issue], meaning the design can continue to go down the road as it is, then it would.”

LIFTbuild now is exploring opportunities in multifamily residential work for its second project. As with WSP and Mace, the process efficiencies of DfMA have excited the LIFTbuild team.

“We have tried to remodel that whole design lifecycle because of the way our building is built,” says Benvenuto. “When you design for more of a manufacturing environment or DfMA, it’s a whole different level. I think the sooner we align the objectives of construction with the objectives of design, the better off we will be.”