DRAPER WATER TREATMENT PLANT REDUNDANCY AND RESILIENCY STRENGTHENING FOR WATER TREATMENT AND STORAGE

Oklahoma City

BEST PROJECT

Submitted by: Carollo Engineers Inc.

OWNER City of Oklahoma City

LEAD DESIGN FIRM/STRUCTURAL/MEP Carollo Engineers Inc.

GENERAL CONTRACTOR Archer Western Construction Co.

CIVIL ENGINEER Olsson Engineering

STRUCTURAL ENGINEER White Engineering Associates Inc.

With a treatment capacity of 150 million gallons per day, the Draper Water Treatment Plant is the largest such facility in the state of Oklahoma and has a more drought-resistant supply than the city’s other water treatment plant.

The primary purpose of this $71-million project was to replace Draper’s clearwells with new ones designed to meet modern seismic resistance standards, improving the facility’s resiliency.

The scope also included construction of a 120-in. transmission pipeline up to 40 ft below grade for a redundant means of filtered water transport to the new clearwells.

The design team conducted geophysical analysis of the subgrade, which indicated that there were unsuitable soils and periodic groundwater at the location planned for the clearwells. A delegated design utilizing ground improvements and a crushed stone transfer pad was deployed as a cost-effective means to accommodate the foundation loads and desired seismic resistance level.

Photo by Skylar Skaggs/Archer Western Construction Co.

The owner, engineer and contractor thoroughly assessed site conditions through selective excavations to better inform the delegated design. This led to a reduction in both cost and schedule for that design element and improved the overall design efficiency.

Recognizing the risk to the existing clearwells from recent seismic events, the team designed and constructed a contingency structure and developed an operational plan to divert the filtered water away from the clearwells in the event of a major failure.

During the planning process, the design team evaluated several options for providing both disinfection and transmission of filtered water from the filters to the new clearwells.

Computational fluid dynamics modeling helped the team evaluate the efficiency of the chlorine contact for disinfection, utilizing an innovative pump mix design.

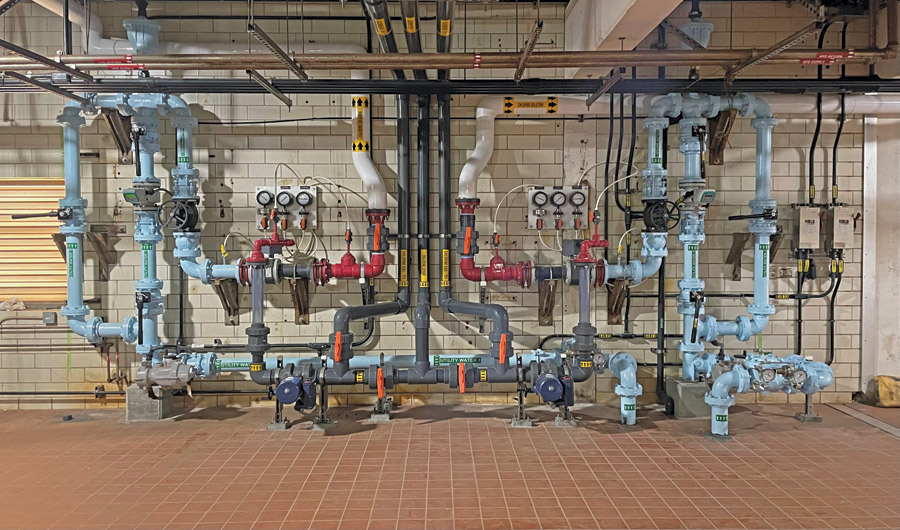

During construction, the team worked with local fabricators to construct an efficient, robust and an easy-to-operate and maintain chlorine injection and diffusion system within the 120-in. pipeline contactor.

Photo by Skylar Skaggs/Archer Western Construction Co.

With greater transfer efficiencies and the ability to disinfect post filtration, the Draper WTP is able to reduce total trihalomethanes entering the distribution system, benefiting the client and community as a whole.

This project had several safety challenges. The first was the trench safety for the 120-ft pipeline that went underneath the existing power supply ductbanks that fed the plant. The Archer Western-led project team used a pier and beam system to bridge the ductbank to open cut the 40-ft excavation in rock underneath this ductbank while keeping it in service.

Another safety concern was installing the coatings on the filter effluent flume while maintaining flow downstream of the work area. Archer Western installed a series of bulkheads to protect workers and to keep the water off the flume section that was being repaired. The work was performed in a confined space with hazard atmosphere (coatings and sand blasting). Permit entry, constant air monitoring, competent training and daily bulkhead inspections were all part of the standard operating procedures, work plan and job hazard analyses for this work.