Construction Managers Embrace 4D BIM for Safety

Jobsite safety is an ongoing challenge.

As preplanning gives way to activities and construction moves through its phases, the site, crews, equipment and logistics erupt into dynamic flow. Keeping the workforce and public safe as the project swirls through its cycles requires that managers be vigilant analysts, aggressive contingency planners, flexible adjusters, great communicators and effective safety trainers.

Contractors say having a clearer picture of how the project will unfold is key to reducing safety risks; four-dimensional building information modeling helps reveal them.

Such models create animated sequences that show a structure's components—including permanent and temporary works, major equipment and laydown areas—according to the timing of the project schedule, typically the fourth dimension in the model.

Planners say 4D BIM helps them coordinate schedules, eliminate conflicts and confusion, improve training and enhance safety by design. The models can help head off spatial conflicts and safety risks that otherwise might go undetected. But useful models must be updated frequently.

"It's not an easy process," admits Scott Kerr, principal BIM integrator at London-based Balfour Beatty Construction Services, which has maintained a 4D model through the life of a complex terminal expansion project at London's Heathrow Airport. The terminal is set to open June 4.

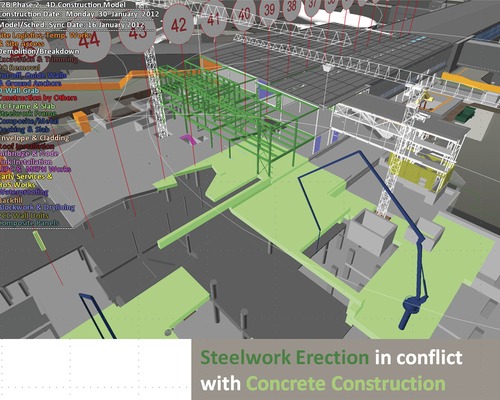

The firm used the project's 3D models from Autodesk Revit, AutoCAD Architecture and Tekla and fed all into Autodesk's Navisworks Timeliner, a schedule animation program, to build its 4D model. Timeliner assigns "exclusion zones" to scheduled activities and equipment locations, represented as objects in the model.

Balfour Beatty updates the model and schedule regularly and runs the 4D simulation each week to create 14-day and 42-day "look-ahead" views of currently planned activities.

Timeliner's conflict checker searches out clashes in space and time between equipment and trades. Activity locations are color-coded in its model, such as structural steel erection flagged for overlapping the exclusion zone for concrete placement.

"When we synchronized the schedule with the model we got that flag," says Kerr. "Potentially we have an issue; something has to give."

"I definitely think the value and benefits outweigh the effort," Kerr adds. "You have to manage the process, the changes and the things that come from left field, and the model can help you understand all of that—but it's a moving beast."

Technology Developments

Contractors, construction management firms, academics and software vendors are working on ways to improve and enhance 4D scheduling techniques. They include automated programs that check 4D models for risks and safety-code violations, based on rules such as those prescribing clearance dimensions, equipment specifications or labor allocations.

In New York City, Jennifer Downey, an architect who manages support services for Turner Construction's Integrated Building Solutions group, is collaborating with city building officials, participants in the autocodes project of research group Fiatech and the developers of Solibri software's Model Checker—a program that analyzes design models for dimensional compliance with building codes and regulations—to flag safety issues during construction.

The Model Checker software runs against a BIM database of thousands of elements in a model tagged with the project's OmniClass Construction Classification System, or Uniformat, numbers.

This identifies an item, such as a men's room—classification number 13-23 17 11—and the associated regulations that apply, such as Americans with Disabilities Act compliance dimensions. The Model Checker flags unclassified objects, as well as objects that fail to meet regulations.

Downey has been modifying Solibri templates to set up runs for construction projects in their various phases, such as excavation or steel erection. She is tagging construction site objects in the model—such as slab edges, openings, gates, flaggers, materials storage points, portable toilets, and fire and life-safety features—to which rules apply on a construction site.

"There is a very long list of requirements for jobsite safety from different international and local authorities, as well as Turner's own requirements," Downey says. "I took the standard rule set and modified it to be safety-related. We have identified 137 items that could be reviewed in a modeling environment."

In the process of modeling, participants can obtain quantities for safety materials, such as linear feet of edge-protection netting.

One early payoff is in verifying the correct placement of fire extinguishers of the proper classifications—which are to be positioned within 75 ft of one another in plain sight, provide full coverage of every floor and be located within 10 ft of stairways.

"For something as simple as fire extinguishers there are a lot of requirements that come into play," Downey says. Running the Model Checker against the model with fire extinguishers in place verifies their correct placement in the plans.

Mojtaba Taiebat, a Georgia Tech University researcher now at DPR Construction, also is developing rules that could be used with compliance-checking software such as Solibri for job-hazard review and to flag potential falls by analyzing openings in unfolding 4D models.

Taiebat proposes his checker be used as part of a collaboration between designers and constructors in an integrated project-delivery format as early as the conceptual modeling stage, as part of a "design for safety" concept.

He says a detailed schedule is not required at that stage, but modeling work locations, scaffolding, formwork, material delivery paths, openings and edges would be.

"The model represents contributing factors of fall hazards and prone-to-error conditions," he explains. Once those factors are simulated and shown to the integrated project delivery team, hazards can be reduced through design alternatives, changed construction methods or altered scheduling, based on the team's experience.

The Great Communicator?

And then there are managers who say when teams of designers, contractors and subs watch planned work unfold on screen together, they are motivated.

As they see objects representing equipment and materials coalescing through time, managers not only pick up on previously hidden conditions such as conflicts between unrelated activities, but they also understand and resolve issues in advance.

"When you look at the site and say 'here is what it's going to look like next week and here's what's going to happen,' people are going to watch a video because it's cool," says Ken McBroom, chief scheduler at McCarthy Building Cos. Inc., Newport Beach, Calif.

McBroom cites a hospital project on which he used 4D project management software Synchro Professional to animate the critical-path method schedule. That is when his plumbing contractor realized that planned roadwork would block a critical delivery, which was quickly rescheduled.

"The plumber is not looking at the schedule of the curb-and-gutter guy. It's not his problem," says McBroom. "That happens a lot because two things don't seem to fit together." But in a 4D visualization, they do.

"It is difficult and time-consuming to communicate a complex construction plan using traditional tools," adds Steve Moore, southern district planning manager for TIC, a Kiewit Corp.-owned heavy industrial contractor.

"Safety personnel do not have time to study stacks of drawings or a 5,000 line-item schedule. It gets even more complicated to visualize the plan as field conditions constantly evolve and change during the project," he says. "[But] 4D gets everyone up to speed on a complex project very quickly, with detailed imagery."

"Critical Path" methods do not give shortest time to complete a project. This was shown in the 1960's by Ronald Graham who in an attempt to shorten the computation time arranged a bank ...

Reducing unhappy accidents, the happy accidents, are the ones that prevent the unhappy accidents is not simple. In fact a new class of unhappy accidents is increasing due to safety regulations each one individually good clashing to create overall unsafe conditions.

Safety rules themselves often need rethinking for example the deepwater horizon accident in the gulf may very well have been prevented if the very experienced drilling crew chief was allowed to continued drilling operations instead of being pulled off the job to attend mandatory refresher training.