Monster Machines Doing Heavy Duty in California

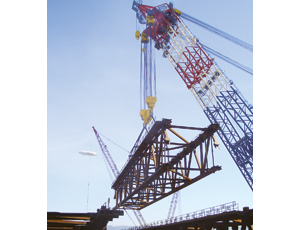

Construction pros are no strangers to heavy equipment, but two new machines working on the eastern span of the $5.5-billion San Francisco-Oakland Bay Bridge make most ordinary tools look like children’s toys.

Mike Flowers, project director for American Bridge/Fluor Enterprises Inc. joint venture, says he knew very early that standard construction cranes just were not up to the job, which is to build the bridge’s unique self-anchored suspension span. “When we started looking at it, we could not find anything here in the U.S. that was even remotely capable of doing what was required,” says Flowers. “The cranes on most bridge jobs might be able to pick 150 tons, and on this project we need to pick pieces that go as high as 1,300 tons.”

The solution was a custom-designed, barge-mounted, shear-leg crane with an impressive 1,700-tonne capacity. But just getting this massive machine—dubbed the Left Coast Lifter—to the jobsite proved to be a major undertaking.

After having the specially reinforced, 100-ft-by-400-ft barge built in Portland, Ore., ocean-going tugs towed it to Shanghai in April 2008, where the Zhenhua Port Machinery Co. built, installed and tested the crane with loads up to 2,000 tonnes. The finished product, with twin 328-ft-long, self-erecting booms, was loaded aboard a 750-ft, semi-submersible cargo ship that sailed under the Golden Gate Bridge in mid-March. The deck had to drop nearly 21 ft to release the barge.

The scale of the $50-million machine boggles the mind. Weighing in at 3,920 tonnes, the crane sports twin 850-tonne hooks along with a single 100-tonne hook and a 10-tonne utility hook. Raising the boom from its minimum to its maximum lifting angle takes more than an hour.

Despite its enormous dimensions, Flowers says the Left Coast Lifter only requires a crew of four. “With its LCD touch-screen displays, video monitors and joystick controls, it has actually proven to be fairly simple to operate,” he says.

As for what happens to the Left Coast Lifter after it has completed its 18-month assignment, Flowers says the joint venture will have to weigh the business implications of keeping the crane and finding more work versus selling it. “Who knows, maybe it will end up on eBay,” he says.

Pump It Up

In addition to 67,000 tons of steel, the Bay Bridge project requires concrete—lots of it. Much of that will be put into place by a Putzmeister 70Z-Meter, the world’s largest truck-mounted concrete pumper.

The truck was the brainchild of Mike Paragini, owner of Associated Concrete Pumping, Sacramento, who approached Putzmeister about building the rig several years ago. He took delivery of the German-built machine last August and has been using it on construction projects throughout northern California and Nevada.

Even by the standards of so-called super-boom concrete pumpers, the 70Z-Meter’s statistics are impressive. The five-section Z-fold boom offers 227 ft of vertical and 213 ft of horizontal reach. The 200-cu-yd-per-hour pump is...