Home » Keywords: » additive manufacturing

Items Tagged with 'additive manufacturing'

ARTICLES

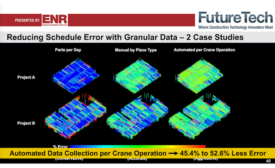

ENR FutureTech Digs Deep Into Construction Data in Action

Conference focuses on the ways contractors, designers and owners use their data

Read More

The latest news and information

#1 Source for Construction News, Data, Rankings, Analysis, and Commentary

JOIN ENR UNLIMITEDCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing