Just as the culture clash between science and engineering is an obstacle, so is the procurement approach involving each of IO's seven members making their contributions in kind, officials concede. "Europe alone could have done it," but the aim was to spread the development effort, says Griffith.

Domestic agencies in each region procure parts of the machine to be shipped for assembly in France. The U.S., for example, is doing 75% of the steady-state electrical network. As part of that deal, ITER U.S. last January had an 87-tonne transformer delivered from South Korea to the Marseilles site.

Europe is delivering the 29 buildings and infrastructure at the 42-hectare site at a cost exceeding $1 billion. The buildings—totalling some 50,000 sq m—will consume 250,000 cu m of concrete, mostly in the Tokamak complex.

The complex is rising from a 1.5-m- thick, seismically isolated base slab in a 120-m-long, 80-m-wide, 17-m-deep pit. The 9,600-sq-m slab floats on 493 elastomeric bearings 18 centimeters deep atop 1.8-m-tall concrete plinths cast on a 1.5-m-thick foundation slab. A consortium led by Paris-based VINCI Group started work in 2010 and completed both slabs and plinths last August.

From the slab, VRF, another VINCI-led consortium, will build the Tokamak complex and other buildings in a $315-million contract awarded by F4E in late 2012.

VRF is working on the first level of walls, which include some of most heavily reinforced concrete in the Tokomak's support system, says Romaric Darbour, F4E's deputy head of site, buildings and power supplies. The team of designers and contractors have tested constructibility with 3D computer simulations and, in March, a full-scale trial concrete placement.

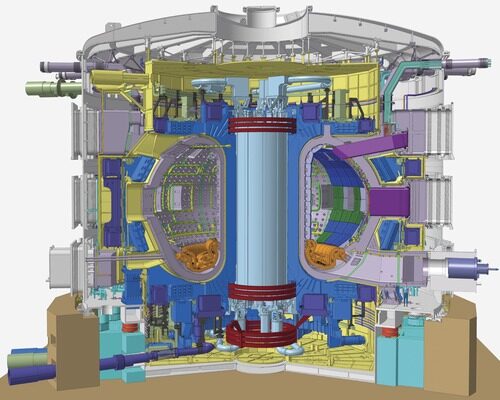

The machine will be founded on 18 spherical bearings distributed around a concrete ring. The ring will be connected to a concrete bioshield by 1-m-thick, 3.5-m-long, 3.6-m-tall radial walls. The Tokamak will be enclosed by a cylindrical, 30-m-dia bioshield that has, in places, walls more than 3 m thick.

Preparing for machine assembly, another team is putting up a 60-m-tall steelwork building next to the Tokamak pit. Six thousand tonnes of steel started to be erected last September, and the 900-tonne roof is due for raising this summer, says Darbour.

At present, IO is preparing to start procuring contracts this June to assemble the machine. By next spring, IO aims to appoint a construction manager to handle three contracts that cover the assembly and the electrical and mechanical installations, says Ken Blackler, head of assembly and operations.

At over $1 billion, the work has roughly doubled in price since 2010 because "the design was not ready," says Blackler. He believes assembly will start in 2017 and end around 2024. But he adds, "We are still working on the baseline."