For John Crocco, building the labyrinthine Perelman Performing Arts Center at Manhattan’s World Trade Center is challenging but also cathartic, because of his history at the WTC site.

On Sept. 11, 2001, at 9:03 a.m., Crocco was standing outside the 110-story south tower of the original 16-acre complex, where he worked on the 21st floor, when the skyscraper “exploded” overhead as terrorists crashed a hijacked plane into the building at the 77th floor. He fled to avoid falling debris.

“This project is very personal to me,” says Crocco, senior project manager for Sciame Construction LLC, the construction manager-at-risk for the 129,000-sq-ft theater, a deceptively simple-looking cube.

Crocco is not alone. Others on the job to create the final public piece—and only performing arts building—at the WTC’s 16-acre replacement complex have strong memories that render the theater special to them and motivate them to overcome the complexities of building three reconfigurable performance halls—with major moving parts—and an exotic iridescent marble skin that changes hue, depending on the sun’s strength and angle.

One of those people is Samantha Gass—a Sciame project manager—though she was only in eighth grade on 9/11. “My father walked down 67 flights of stairs” to flee the south tower, Gass says.

He got out before the collapse at 9:58 a.m., which was 30 minutes before the north tower fell. Crocco’s colleagues in the south tower also survived.

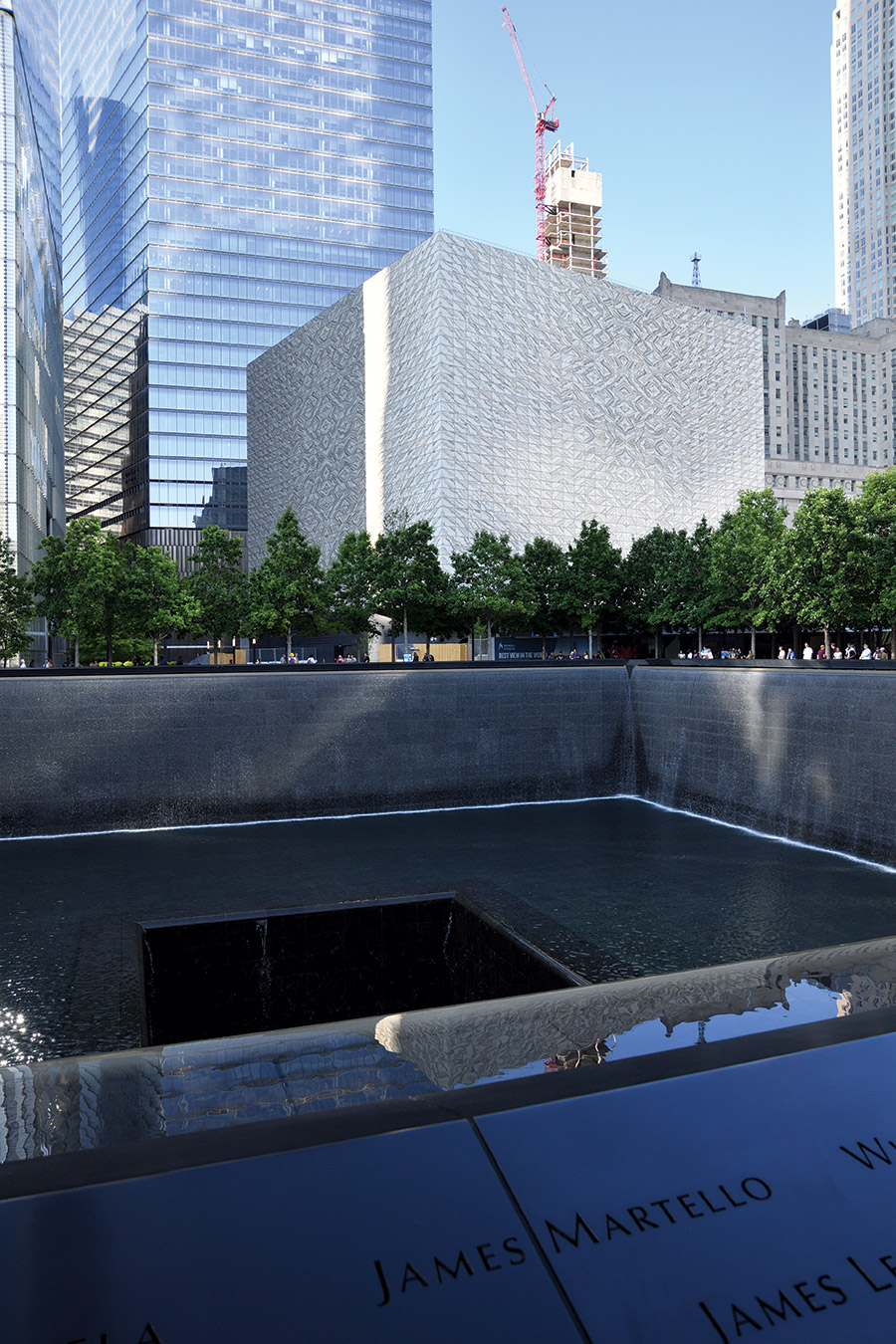

By day, the cream-colored theater box fits unobtrusively into its environs, but by night, it is transformed into a glowing lantern behind the north reflecting pool.

(Top) Photo by Tom Sawyer; (Above) Photo by Nadine M. Post/ENR

On that day that rocked the world, the terrorists killed 2,753 people at the WTC, injured many others, destroyed the buildings in the 10-million-sq-ft complex and sucked the vitality out of Lower Manhattan. The catastrophe inspired the 2003 WTC master plan, by Daniel Libeskind, that would improve upon the original WTC, as a way to honor the victims, help with healing and revitalize the area (ENR 8/15/11 p. 14).

A diminutive 160-ft-square cube, only 117 ft tall, the theater box itself sits on a 21-ft-tall plinth clad in black granite, interrupted by a grand entry staircase. The $500-million PAC NYC, as it is nicknamed by the nonprofit that owns it, opens in September. Major funding includes $130 million from former Mayor Michael R. Bloomberg—PAC NYC’s board chair; $100-million from the federal government via the Lower Manhattan Development Corp.; and $75 million from financier Ronald O. Perelman.

The eight-story theater sits in the center of the north side of the WTC site, due east of One WTC—the 1,776-ft-tall single replacement for the destroyed twin towers. The theater also is near Santiago Calatrava’s exuberant World Trade Center Transportation Hub, which houses the PATH subway terminal of the WTC’s landowner, the Port Authority of New York and New Jersey, as well as entrances or pedestrian connections to 12 New York City subway lines.

The theater sits next to the 1,776-ft-tall One World Trade Center to the west, near the ribbed World Trade Center Transportation Hub and a stone’s throw from the 9/11 memorial’s north reflecting pool.

Photo by Iwan Baan

Most significantly for the design architect, REX, the theater is within a stone’s throw of the north reflecting pool of the 9/11 Memorial and Museum. The proximity informed the architecture.

By day, the “pure elegant” form of the theater, clad in light cream-colored, dark-veined translucent marble, is a backdrop to the memorial, says Joshua Ramus, founding principal of REX, which in 2015 won an international competition to design the theater, in a collaboration with Davis Brody Bond, the executive architect, and Charcoalblue, a theater consultant.

The regular form and daytime color are purposely subdued, deferential to the 9/11 victims, their families and other visitors. But at night when the memorial is closed to the public, the demure box, much like a chameleon, transforms into a golden beacon, lit from within. “We had the idea of a lantern—a heart glowing,” says Ramus.

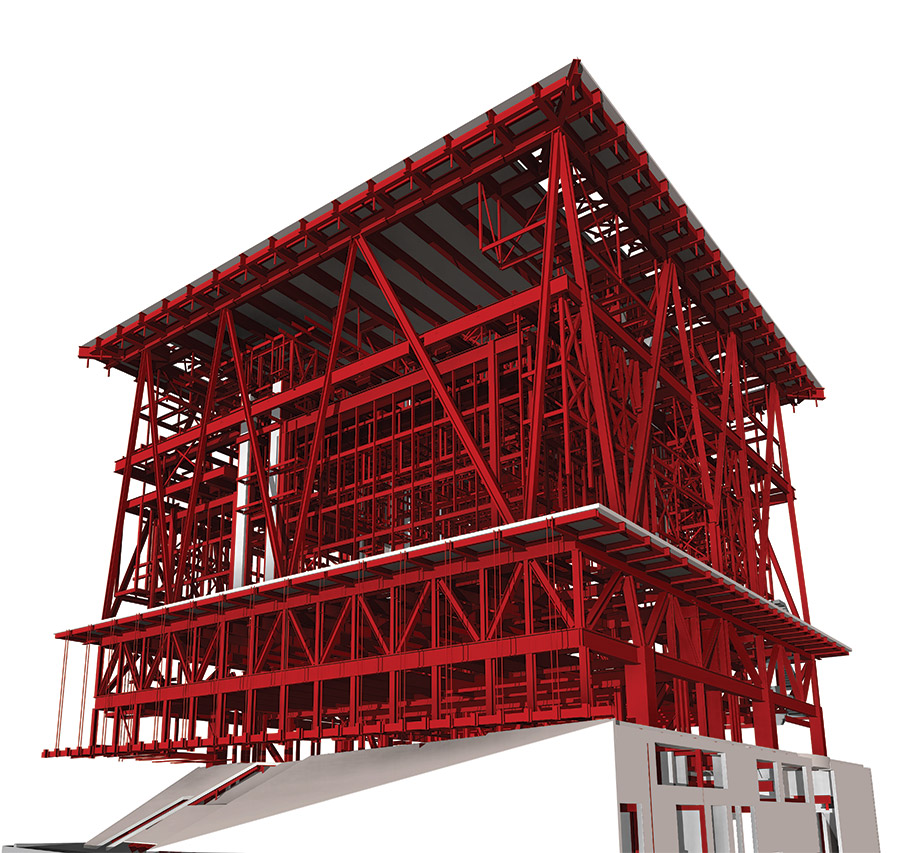

Steel erection started with the seven supercolumns and continued with the preassembled lower truss section of the 104-ft-deep belt truss (left). The 85-ft-deep upper section of the belt was stick-built (middle). Staging space for all the structural steel was limited, which forced mostly just-in-time deliveries.

Photos (Left and right) Courtesy PANYNJ; (Middle) by Aaron Thompson

Another person on the theater project with early history at the WTC redevelopment is long-time Lower Manhattan booster Frank Sciame, the contractor’s founder, chairman and CEO. In 2006, then Gov. George E. Pataki and then Mayor Bloomberg recruited Sciame to form a pro bono team to bring down the cost of the 9/11 Memorial and Museum after bids came in a whopping $470 million over the $500-million budget.

Sciame had a memorable conversation with the late John C. Whitehead, who led the Lower Manhattan Development Corp., responsible for the rebuild. Whitehead said, “Frank, I really will leave it to you to work out the memorial, but don’t touch the performing arts center. Without culture downtown, Ground Zero will never be successful.”

Sciame gave Whitehead his word. It would be “hands off the theater” during the value engineering.

Because of his promise, winning the PAC NYC job was almost providential for Sciame. He saw the obstacles— imposed below grade by existing port authority infrastructure and above grade by a tight site with limited access, strict security, intense logistics and a precise Swiss-watch-like design—as opportunities. “We embrace the tough ones,” Sciame says, adding he recently even told the architect to make the punch list “tough.”

Like Sciame, David Williams has a direct connection to the 9/11 memorial. In 2004, Williams joined Davis Brody Bond, the memorial’s executive architect and architect for the mostly subterranean museum, specifically to run the memorial project. When recruited, Williams dropped everything. “I’ll be there in two weeks,” he recalls saying. He stayed 100% immersed in memorial work until it opened seven years later, in 2011.

Williams, currently a partner, delayed retirement for two years, until September, to finish the theater. For him, the job is a career-topper and a swan song.

A requirement to use existing foundations designed and installed for a larger theater, never realized, complicated engineering and pushed the structure, including a 104-ft-deep belt truss and its perimeter supercolumns, to the edges.

Graphic by MKA

PAC NYC also is a career-topper and retirement-delayer for structural engineer Jay Taylor of Magnusson Klemencic Associates. A presence at the WTC site is important to MKA because its predecessor firm led by John Skilling was the structural engineer for the twin towers, completed in 1972. “We have history at the site,” says Taylor, an MKA senior principal-retired.

Taylor also has his own history at the WTC, dating to 2004. He was MKA’s project manager for the first effort to build a much-larger performing arts center in the same location, designed by architect Frank Gehry.

The project fizzled, but only after foundations were built in the WTC’s four-level basement, called the bathtub, based on MKA’s load requirements but engineered by WSP.

Built out early in the redevelopment, the bathtub contains the PATH, port authority infrastructure and foundations and power infrastructure for all the WTC buildings. There was no space left for the new theater’s foundations. MKA had to use the existing WSP foundations outside the smaller PAC NYC footprint.

The port authority only gave MKA seven points for seven supercolumns to transfer loads from the theater to the WSP foundations, which had limited bearing capacity.

That forced MKA into a structural straightjacket. “We had to reverse engineer the building from the bottom up,” says Taylor, because “more than 60% of the footprint could not have a column.” That restriction pushed the structure out to the edges, he adds.

One of the three reconfigurable halls takes shape, with the belt-truss’ lower-chord truss and the tall upper-chord V-shaped web members still visible. Hall framing was erected without shoring.

Photo by Aaron Thompson

The situation, which forced an obsession with building weight, had a ripple effect. MKA selected structural steel because of concrete’s mass. That in turn made mechanical system steel-wall penetrations trickier.

In an intense collaboration, based on MKA’s new- theater loads, WSP engineered seven “interventions” that would transfer supercolumn loads, six along the box’s perimeter and one internal, from the theater box’s 104-ft-deep belt truss to the WSP foundations.

The theater is packed with 6,300 tons of primary steel, ten times the tonnage of a six-story office building MKA is designing. PAC NYC is “pound for pound, the most complex project MKA has ever done,” says Taylor.

The theater’s reconfigurable halls, designed with Charcoalblue, can remain separate or be combined into one or two halls. More than 55 stage and seating set-ups are possible, thanks to movable feats that include walls—called guillotine doors—that rise into mechanical space above the ceiling and disappear, a performance hall floor on lifts, rolling seating towers and removable seats.

“A theater is a complex animal,” says REX’s Ramus, who has designed two other theaters, both with MKA. “A reconfigurable theater increases that complexity,” he adds.

At the “mystery box,” as Ramus calls it, the biggest self-imposed complexity is static—the iridescent stone curtain wall. The vein pattern on each face consists of “calm zones” near the edges and “turbulent zones” in the center, says Ramus, who collaborated with facade specialist Front to design the exotic skin.

Spiralifts in trap area under largest hall work like Slinky toys to raise and lower floor sections, allowing myriad stage and seating configurations (above). Seating tower sits in scene dock between guillotine doors—hoistable walls that allow performance halls to be combined (right).

A Real Nail Biter

The facade is composed of 4,896 insulated glass units. Each 5 ft x 3 ft panel, weighing 300 lb, is a laminated sandwich of an outer pane of antiglare protective glass, a ½-in.-thick panel of dark-veined translucent marble from the Estremoz region of Portugal and another pane of glass.

To Joseph Mizzi, Sciame’s president and chief operating officer, the most complicated and gratifying single system is the facade. Contracting it was a real nail biter due to the difficulty of finding a supplier at the budgeted cost. REX even had an alternate conventional scheme designed, in case the translucent skin didn’t pan out.

Mizzi recalls calling Ramus from his cell phone, out of sheer excitement, after solidifying the deal with the curtain wall supplier, Gartner. “We have secured the facade,” he said. And throughout the cladding installation, Mizzi sent Ramus cellphone photos.

The plinth houses back-of-house functions plus accessible and staff entry. The lobby, open to the public with a corner stage for free performances and a restaurant, is level two of the eight-story building. An indoor perimeter corridor, with the marble skin exposed on one side, wraps all four sides. The corridor is accessible to the public at the lobby level, and to ticket holders at the performance halls on level four. At the lobby level, the vertical expanse of iridescent marble on view is 30 ft. At the theater hall level, it is a sweeping 78 ft.

The corridor is outbound of the 104-ft-tall belt truss, which consists of a 19-ft-deep bottom chord truss and an 85-ft-deep upper portion, with built-up box sections as web members. All gravity and lateral forces are transmitted by the floor diaphragms to the belt truss, then finally through the supercolumns to the WSP interventions.

All interior structure, including two-story trusses at two levels and roof trusses in the interstitial mechanical level just below the roof, transfer loads directly to the belt truss, except in one instance where loads are transferred, via a girder, to the single interior supercolumn.

Almost nothing is repetitive. The supercolumns are built-up box shapes, dimensionally varied. They range in length from 39 ft to 18 ft, depending on their landing points. The interventions also vary. They consist of built-up plate girders up to 8 ft deep, trusses up to 29 ft deep or, in one case, a supercolumn directly spliced to a built-up WSP column.

Theater cube sits on a granite-clad plinth. Entry stair is a stone’s throw from the north reflecting pool of the 9/11 Memorial and Museum. Edge corridor offers sweeping inside views of the translucent marble cladding at lobby and performance hall levels. Halls can be combined by raising walls between them. Roof has no equipment.

Graphics (Left) by REX; (Right) by Chris Janjic

The supercolumns are pinned at the port authority structure and therefore restrained against movement in all directions, but with no ability to resist moment. “This results in the supercolumns acting as inverted cantilevers,” similar to chair legs, says Peter H. Range, MKA’s project manager for construction.

All lower belt-truss nodes at supercolumn locations are welded to allow for as much tolerance as possible, adds Range. The nodes are as large as 18 ft x 5 ft and as small as 5 ft x 4 ft. The heaviest weighs 16 tons.

Taylor likens the project to building three ships in a bottle because each hall is structurally independent and acoustically isolated.

By all accounts, construction planning was as challenging as design. At every value engineering moment, REX’s Ramus issued a reminder to the team to hold firm on the reconfigurabilty, the pure form and the “transformative” stone exterior, he says.

Coordination was especially difficult, says Mizzi. The biggest headaches concerned the interrelationships of the major building systems—the facade, the MEP systems and the structure. “We had some animated conversations,” says Mizzi.

Translucent marble curtain wall, made of nearly 5,000 units, changes color and character as the sun hits it, transforming its appearance both for those outside the building and for those in the interior perimeter corridor, where the veined stone is expressed.

Photos (Top) Copyright Field Condition; (Above) by Laurian Ghinitoiu

“The MEP systems touched every trade,” he adds. “Our stress level was heightened early on because we had to release the steel order,” including MEP duct cutouts, before the penetrations are typically located, he says.

Steel erection began in September 2019, with the installation of a supercolumn in the site’s northeast corner, and proceeded counterclockwise until all seven were installed. Steel topped out in late June 2021.

Limited laydown and staging space meant mostly just-in-time deliveries through the site’s two access points, on the north and south sides.

Steel contractor and fabricator Cimolai S.p.A., based in Rome, and steel erector Stonebridge Inc. were awarded the project in October 2018, because they had a plan to split the bottom chord of the belt trusses in half, which allowed them to preassemble members overseas, says Sciame’s Crocco. They also were able to erect the performance hall steel without shoring.

The schedule was “very tight,” said Federico Tosi, Cimolai’s project manager, in an email. Fabrication started in January 2019 to send the first shipload—700 tons of steel—that June, for arrival a month later.

Big pieces, which accounted for more than half the total tonnage, were shipped from Cimolai’s workshop in San Giorgio di Nogaro, Italy, which has a private quay. The rest traveled on container ships.

Stonebridge used two cranes, one on the north side and the other on the south. “This gave us the ability to use the cranes to install the curtain wall and in addition work on the interior spaces without the disruption of having to dismantle a crane,” says Crocco.

On the east and west sides, there was no need to use falsework due to the smaller distance between the supercolumns. But on the north and south sides, crews erected the preassembled lower truss section of the belt truss on shoring towers—tridimensional reticular sections, founded on WSP’s structure on the north side and on the concrete slab on the south. After crews set opposite ends of the trusses between a supercolumn and falsework, they filled in the midsection.

Each steel section was installed in a sequence determined by Stonebridge’s erection engineer. This was challenging, says Crocco. Some areas couldn’t be erected before others. For example, a section of the eighth floor had to be built first to erect the fifth, sixth and seventh floors because the lower-floor steel hangs from the eighth floor structure.

Tosi agrees the most demanding part of the operation was not the belt truss but rather two interior two-story trusses at level eight. The trusses are each 38 ft deep and 138 ft long, and the space available in the field for crane placement and erection was very tight, he says.

The two trusses—one on the north and the other on the south side—were preassembled on the ground in three sections to create the depth. This made geometric control difficult, says Tosi.

“There was no space inside the building to set any temporary tower, so we had to put in place temporary stubs, using parts of the steel structure below, to temporarily transfer the load during the erection,” Tosi explains.

Some interior trusses were erected in pieces using stubs or shoring. One piece was erected on hydraulic jacks that spread the loads on a concrete wall in the bathtub. This was necessary to maintain the predetermined value of camber on this truss during erection, says Tosi.

Theater’s cube, lit at night from within, is a quiet backdrop to the 9/11 Memorial during the day.

Photos by Tom Sawyer

Intensive Materials Production

As with the steel, the cladding also had a long journey to the site. It began at the marble quarry in Granoguli and continued at the stone fabricator in Pedreiras, Portugal.

The glass-and-stone layers were laminated at a plant in Lyon, France. The insulated glass units were then produced in Plattling, Germany. Finally, to streamline installation, curtain wall elements were fabricated into 1,200 four-piece megapanels in Gundelfingen, Germany, before being shipped to a warehouse in New Jersey to await delivery to the site.

Gartner was awarded the contract to supply the curtain wall because of its production capabilities, design-assist capabilities and an understanding of the intensive material production process, says Robert D’Agostino, Sciame’s project manager for the skin.

The stone has a distinct vein pattern when cut in a certain direction, he explains. Each facade is book-matched and almost exact on all four faces.

The design team selected every stone piece through a virtual program and designated it for a specific location on the facade. The fabricator had scanners set up to take images of the stone to facilitate this process, says D’Agostino.

Curtain wall installation started in July 2021 with the steel backing. Megapanel installation started in October of 2021 and was completed that December.

Crews installed the megapanels from the bottom up. Each megapanel is fit up and then set down into its clip. Due to the clip system, if you installed from the top down on the face, the installed panel above would block the installation of the panel below, says D’Agostino.

The work went very smoothly, with no fit-up issues, thanks to all the logistical planning, he adds. “The only breakage was individual stone-glass pieces that were able to be replaced,” says D’Agostino. Some of this either occurred in transport or once installed.

The MEP systems, designed by Jaros, Baum & Bolles, also presented challenges. The halls are acoustically separated from the rest of the building, making MEP cross connections difficult, says Mizzi.

Also, the roof is clear of MEP equipment. And there was limited shaft, plenum and back of the house space for MEP infrastructure, which significantly increased the difficulty of coordination and required precise execution in the field, Mizzi adds.

The performance halls are topped by interstitial mechanical space below the roof. The halls hold a maximum 450 seats, 250 seats and 99 seats. They are enclosed, on either one or two sides, by four liftable guillotine doors, similar to pocket doors but hoisted vertically, designed and fabricated by Clark Door Ltd. and installed by SISSCO Material Handling.

The doors are actually walls, with two-hour fire ratings and acoustical isolation. They allow the halls to be configured 10 ways, says Sciame’s Gass. The walls outline scene dock corridors between the halls. Clad with millwork on the hall side, they blend in if not raised.

The two walls between the larger theaters are 65 ft wide and 32 ft tall and weigh 50 tons each. The two that separate the smallest hall from the medium size hall are 40 ft wide and 23 ft tall and weigh about 25 tons each.

Each wall has four motors and two safety lockbars. When lowered, walls bear on steel plate channels. When raised, the lock-bar engages, much like a dead bolt, into receivers at the top of the walls to hold the load. The walls’ hoists are a counterweightless system with cables around a drum. That allowed a slim profile for the door pocket, says Gass.

Like a Slinky Toy

In addition to the kinetic walls, the largest hall has floors that raise and lower via a compact Spiralift system supplied by Gala. It is installed in the trap level below the hall floor and bears on the third-floor slab. Spiralift uses bands of intertwining steel to form a strong and stable column that can be extended or shortened, like a Slinky toy, says Gass. There is no pit or piston.

The system has over 50 Spiralifts that move 17 floor sections at 5.9 ft per minute. Maximum lifting capacity is 22,500 lb, with a maximum static load of 45,000 lb.

The movable components are all camouflaged to look stationary. They are part of the design intent to suspend disbelief to theatergoers and offer surprise for repeat customers who don’t know what configuration to expect from visit to visit, says Jerad Schomer, director of Charcoalblue. “Artists are empowered to create [different] environments, which engages theatergoers,” he adds.

In the end, the intricate puzzle of moving and static pieces did fit together. But as REX’s Ramus says, “making something look simple is extremely difficult.” And MKA’s Taylor adds, at PAC NYC, “no one will ever know the extent of the effort to make things look simple.”