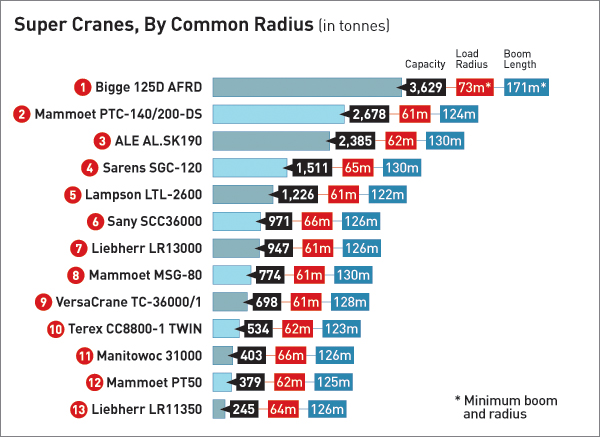

The World's Biggest Supercranes

"It usually has some prep, but it is not super-extensive," he says. Deep South has built two 36000s and another on the drawing board. One is working in Colombia at a refinery—the company's first time using the crane abroad.

Transportation is another consideration with supercranes. Some cranes, such as the Mammoet PTC, are designed to ship in containers, which then become ballast boxes for the crane. Users are instructed to fill the boxes with local materials—such as sand and gravel—to provide the proper counterweight. Lampson's crane breaks down into about 100 truckloads, and the boom pieces are pinned, not welded, which cuts down on wasted space during transport.

The Bigge-built supercrane travels in about 160 truckloads. Instead of using a traditional counterweight, its central ring bears down on a 4,500-tonne mass of concrete and steel in the ground. Its dual rings bear on spread footings.

Will crane capacities keep going up? Most interviewed for this story believed they will. Ashton says Bigge is working on a design that is "quite a bit bigger" than its current machine. Meanwhile, he adds, the engineering found inside these supercranes is something to celebrate.

"Everybody loves a crane," Ashton says. "It is the most exciting part of the construction industry."

rruggle, I think you have missed the point of this story—the information here is the result of countless hours of research, interviewing experts, consulting with engineers and studying ...

Thank you Mr Vanhampton for an article I consider one of the more solid articles<br/>appearing in ENR. I do appreciate the work you put into the article.<br/><br/>It is the translation ...

appearing in ENR. I do appreciate the work you put into the article.

It is the translation of 2500 in one system of units to 2268 in another system of units

I object to. I would round 2268 to 2300 so there would not be spurious accuracy. More

importantly with fewer digits there is a lot less chance of getting the number wrong and

here any transposition error is on the side of danger eg 2628 for 2268.

If concern is felt that 2300 is larger than 2268 perhaps a standard can be written so there

is rounding down ( the official name for this is truncation and truncation has the additional

benefit that it is less error prone than rounding).

Flatly put, not too diplomatically put, all the experts you consulted on the conversions

are wrong. My guess is that they just did not give the matter the attention it deserves.

Again I want to thank you for a very worthwhile article.

Sorry rruggie, it appears to me that you are making an unverified assumption. Not all zeros are insignificant, and just because a crane’s capacity is named to a rating of so many hundre...

Since the load limit is essentially a guarantee, or a safety limit, it appears to me that the limitations on the limit are the accuracy of the field measurements of load amount, lift radius, and similar factors. In this case, the comparison numbers are assigned, not measured, so they have no inaccuracy. You may argue that no one will measure the loads that accurately in the field, but that does not make the rating comparisons wrong. In theory, and I believe in fact, they are as accurate as your field measurements, and different applications will have different accuracies in the field.