Articles by Jeff Yoders

Information Technology

Autodesk Acquires Payapps, Maker of GCPay, to Compete in Payments

Acquisition of payments platform provider aligns Autodesk to compete with Procore and Oracle

Read More

Construction Technology

Oakland 'Phoenix' Multifamily Project Uses Industrialized Construction, Mycelium

Read MoreMaterials

Lower Sioux Developing First US Hempcrete Production Facility

Southern Minnesota tribal community is building homes with homegrown hemp materials

Read More

ENR 2023 Top 25 Newsmakers

Tom Murphy Jr.: Spearheaded Development of Potentially Game-Changing Building System

Read MoreENR 2023 Top 25 Newsmakers

Joe Benvenuto: Pioneering an Uplifting New Construction Delivery Method

Exchange is the first U.S. use of top-down construction since the '70s,

Read More

Information Technology

Sage Acquires Bridgetown Software, Creator of BidMatrix

Acquisition brings cloud capabilities to Sage Estimating

Read More

Economics

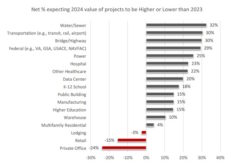

AGC Survey Finds Mixed Outlook Among Contractors for 2024

Robust infrastructure, public work seen as one potential bright spot

Read More

Transportation

Gordie Howe Bridge Completion Pushed Back to September 2025

Canada-US crossing cost swells to $4.7B due to pandemic, unknown conditions,

Read More

Equipment

Cummins To Pay Record $1.67B to Settle Claims of Bypassing Emissions Tests

Settlement will be the largest ever under the Clean Air Act if paid in full

Read More

The latest news and information

#1 Source for Construction News, Data, Rankings, Analysis, and Commentary

JOIN ENR UNLIMITEDCopyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing