Technology

Generative Design Helps Quebec Wood Export Bureau Plan, Ship Multi-Use Disaster Shelters

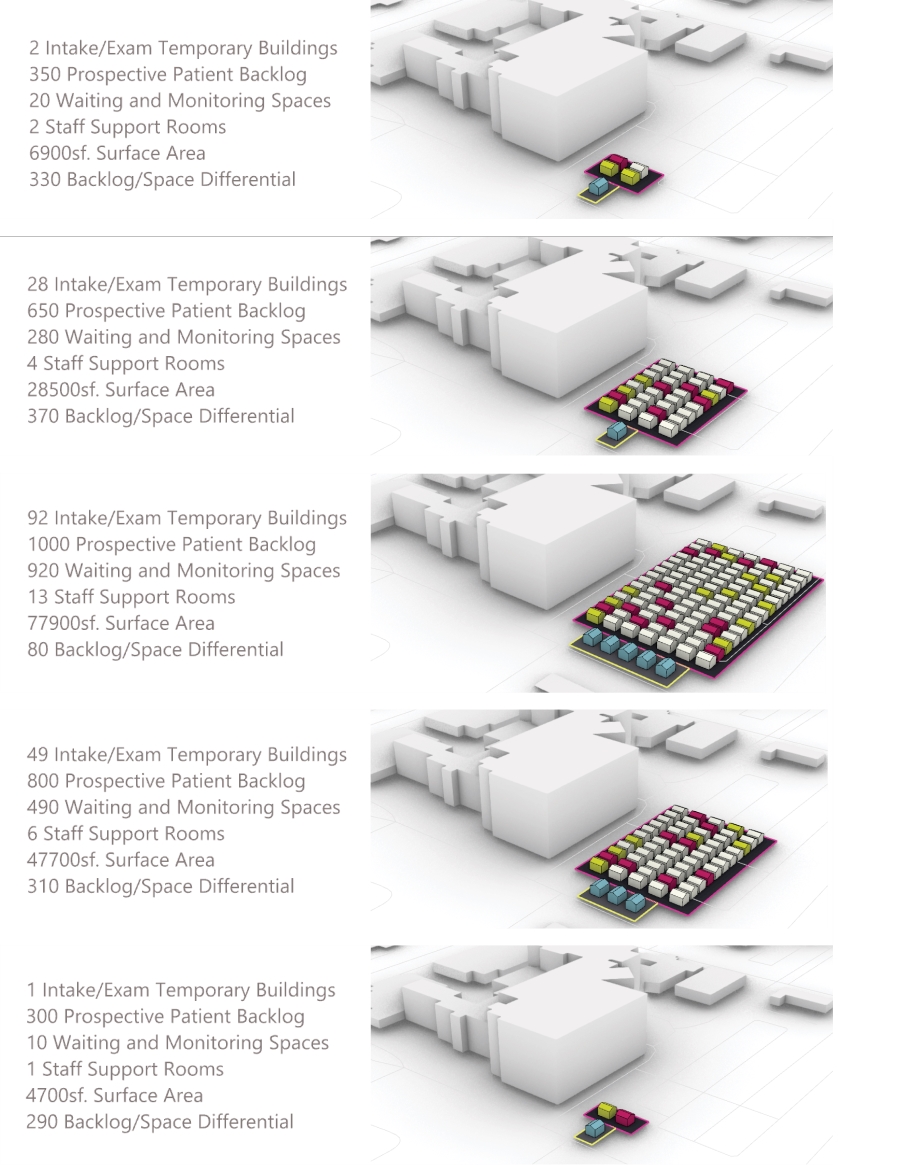

VIATechnik's generative system creates different versions of shelters for disaster relief

Chicago-based virtual design and construction consultant VIATechnik was already working with the Quebec Wood Export Bureau in March on a generative design solution for rapidly deployed wooden structures for responding to disasters such as floods, hurricanes and refugee crises. Then came the COVID-19 global pandemic crisis, with its attendant healthcare facility shortage.

[For ENR’s latest coverage of the impacts of the COVID-19 pandemic, click here]

Working with QWEB, VIATechnik had developed a VDC strategy to optimize not only the generative design but the shipping, assembly and site logistics of temporary, prefabricated relief structures, but the parameters of the project has since changed with the times.

“We kind of did a whole second round with them [as the extent of the COVID-19 pandemic became clear],” says Mac Little, a VIATechnik computational BIM lead who led the generative design workflow on the project. “I said, ‘Hey well why don't we take this idea, re-vet it and then reset all of these things so you can come in and pick surface areas and see how things populate, increase or decrease the area based on a patient flow.”

Using a plugin workflow with Grasshopper and Unreal Engine, VIATechnik was able to quickly iterate various site layouts of QWEB’s prefabricated structures, accounting for differences in climate and building orientation, as well as site footprint and terrain, without having to manually redo the modeling work.

The prefabricated buildings are built with renewable materials, such as wood, and can be moved to other locations for healthcare uses such as COVID-19 testing structures, alternate care facilities for patients and as structures for families at home so as not to expose them to infection. Logistics are also including in the project, allowing QWEB's 200 member companies to quickly fabricate the primarily wood-based components of the structures and ship them out via Canada's rail and port network.

By using a generative design, the program can adjust it's parameters as needs rise and fall, and allows disaster-response agencies to quickly plan and test out designs for new locations.

“We looked at the parameters, the sites, how you would actually use this [structure], what that would look like,” asked Little. “What do you want to scale, is it density, is it community spaces, do you want actually more space instead of having these dense populated refugee camps?"

The structures themselves are compact enough to be put together onsite by small teams from agencies or disaster-relief organizations.

Eli Gould, QWEB's U.S. representative based in Vermont, said the structures have already been specified for use in the Bahamas and QWEB would welcome any opportunity to work with relief organizations in the U.S such as the American Red Cross or Team Rubicon. The company is also open to working with U.S. government entities such as the National Guard and the U.S. Army Corps of Engineers, which have been tasked with setting up COVID-19 testing sites and alternate care facilities in cities and towns across the country. says Gould.